The present fast-paced and dynamic scenario in the world of electronics requires it more than ever before that PCA/PCBA and IC designs be reliable and functional. As technologies and devices develop at a rapid rate with a focus on efficiently serving complex needs emerging with IoT, AI, and 5G, a result-driven practice like Design for Testability or DFT plays an integral role. Through this article, it shall be explored how DFT can be done with advanced tools and techniques.

Increasing Relevance of DFT

Design for Testability, or DFT, is an area that focuses on incorporating testing functionality into PCBA designs and IC designs. DFT testing leads to substantially shorter testing times and better fault coverage at a reduced cost. As IC designs get more complex due to advancements in 3nm process technologies and multi-billion transistor designs, DFT has become an essential area.

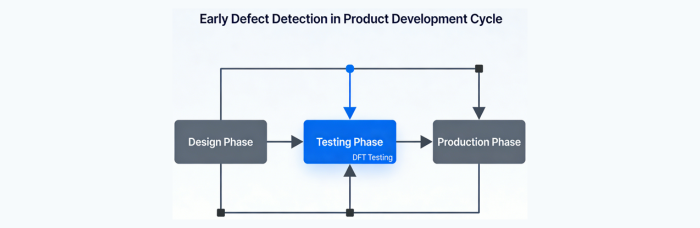

Early and Efficient Fault Detection

It would be difficult to identify more essential benefits associated with DFT compared to its applicability in identifying production defects at early stages of product development. By identifying these defects at early stages, it becomes easy for producers to remedy these problems without engaging in redesigns and thus result in high customer satisfaction.

Effective Testing of Complex, High-Density Designs

Contemporary electronic products usually include tightly packed components with high-speed operations. These raise additional challenges to conventional testing procedures. DFT techniques make it easier to get access to critical testing points and improve diagnostic functions. They make it possible to carry out testing on complex designs.

Reducing Test Escapes

Although no testing method assures 100% fault coverage, DFT greatly decreases the possibility of test escapes. Test escapes occur when faulty products are missed at the testing stage. Reducing these occurrences helps prevent expensive repair and ensures superior product reliability.

Expert DFT Methods for 2025 and Looking Ahead

Hierarchical DFT

Hierarchical DFT helps deal with very large IC designs. Hierarchical DFT decomposes large IC designs into more manageable chunks. It helps test various chunks parallely, thus significantly reducing the amount of data required and testing time. It proves very useful for testing large ICs with billions of transistors.

Power-Aware DFT

Power-aware methods play a vital role in testing because they help in avoiding the violation of optimal power constraints. Moreover, they have specific importance for battery-driven designs, including IoT and mobile processors.

At-Speed Testing

At-speed testing, common in high-speed technologies like 5G, implies Built-In Self-Test (BIST) sections working at full operational speed. At-speed testing helps detect defects related to timing, which might have been missed at slower testing speeds. It thus ensures that the component will work as it should at its optimal use environment.

Applying Contemporary DFT Technologies

By 2025, the role of modern DFT solutions becomes imperative, incorporating automation, artificial intelligence, and cloud functionality into testing:

Automatic DFT Insertion: The task of interconnecting scan chain and test points is made automatic, thus eliminating any possibility of error. It reduces the project duration.

AI-Powered Fault Analysis: AI tools make use of designs to predict regions that can potentially have faults and thus improve fault coverage significantly.

Cloud Test Simulation: Clouds allow simulations involving a large number of tests without requiring expensive equipment, as multiple operations can be performed concurrently, thus shortening simulation times.

Automating Test Pattern Generation

ATPG tools are essential for realizing high fault coverage requirements, as prevalent in dense designs. These tools automatically generate vectors for testing different fault types. As a result, these tools offer comprehensive testing capabilities even for intricate designs.

Test Flow Scripting Integration

Scripts for automating processes involving DFT that are included within the overall design flow, from synthesis and through place-and-route, assist in cutting down on iterative designs and getting a product to market faster.

Real-Time Test Monitoring

Automated monitoring systems offer facility members real-time feedback during testing so that they can adapt and make changes on the spot. This will eliminate wasted time on large-scale debugging and failure analysis.

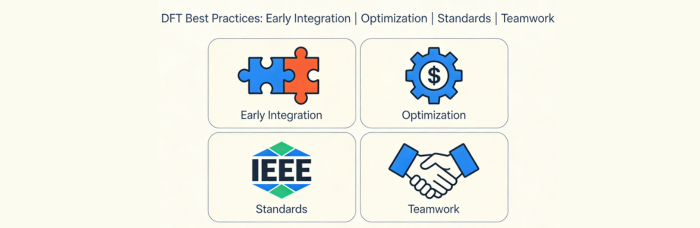

Best Practices for DFT Implementation

Effective DFT implementation requires a set of best practices that can be formulated to deal with the challenges posed by today’s advanced electronic designs:

Integrate Early: Integrating DFT planning with initial design processes reduces costs associated with redesign and ensures that DFT planning meets design criteria.

Optimize Test Time and Cost: Test data compression and parallel testing methods are employed to optimize testing costs and times.

Use Industry Standards: Use standards like IEEE 1149.1 (JTAG) for boundary scan testing. Industry standards make testing and debugging easier.

Facilitate Teamwork: It inspires cooperation among the design and test teams for easier optimization of DFT. It addresses problems from an overall perspective and shortens the resolution of issues by as much as 30%.

Overcoming DFT Challenges

Although DFT has its benefits, there are challenges associated with its implementation in modern designs as outlined below:

Handling Test Data Volumes: As designs increase, so does the size of the test data. Use data compression algorithms and cloud services to effectively deal with large volumes.

Balancing Test Coverage and Power Consumption: Having high test coverage leads to high power consumption. Use power-conscious testing methods that allow you to maintain safety within acceptable levels of power consumption.

Verifying Heterogeneous Designs: Modern semiconductor chips are increasingly more likely than older designs to include digital, analog, and RF components within a single chip. To effectively check these designs, industry professionals rely on mixed signal DFT solution tools and methods.

As we proceed into an age where rapid technological progress becomes more pronounced, learning about effectively employing DFT advanced methods becomes an imperative for businesses seeking to be at the cutting edge of the highly competitive world of electronics. By taking advantage of early planning methods and making use of collaborative and advanced technologies and tools, it becomes possible for experts to derive maximum benefits and achieve more efficient transition times and a higher cost-effectiveness.

At PCBCart, we are dedicated to providing you with world-class production and assembly services and are bound by the strictest standards on quality. We have extensive knowledge and expertise that will ensure your PCBA and IC designs not only live up to but surpass market standards, and as a result, you will have created something truly remarkable and successful. From IoT, AI, and 5G technologies, no challenge will be too big as you bring your next-gen designs into life with our unparalleled precision and quality. Let us help you today with a consultation and a competitive price for your revolutionary electronic solutions.

Get an Instant Quote for High-Quality PCB Assembly

Helpful Resources

• Automated Optical Inspection

• Automated X-ray Inspection

• PCB Assembly Inspection Methods

• Electrical Test

• First Article

• Free DFM Check