Within the rapidly expanding and competitive realm of the electronics industry, it will not be an exaggeration to state that Printed Circuit Boards (PCBs) form the backbone for almost all products. To optimize and reduce costs for PCBs will remain an important task for various businesses and technocrats. PCBCart, as a prominent player with rich experience within the domain of high-quality PCB manufacturering and assemblies, realizes that cost reduction remains an on-going process and not merely an act based on intelligent designs. This article aims at unscrambling various cost drivers associated with PCB manufacturering and exploring ways and means on which cost savings can be achieved without sacrificing an inch on quality.

Main Cost Drivers in PCB Production

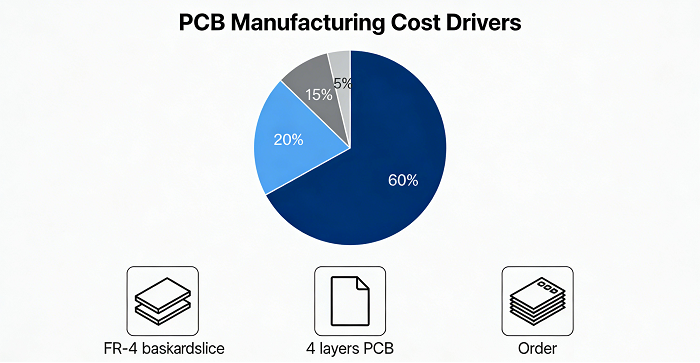

Prior to examining methods of cost savings, it becomes necessary to discuss factors that affect PC board pricing. Four major factors influencing PC board prices have been identified based on PCBCart’s production statistics. These factors combine for more than 90% of PC board costs and are as follows:

1. Material Expenses: Contributing approximately 60% towards overheads, materials comprise substrate materials such as FR-4 and Rogers, copper foil, solder resist ink, and surface finishes. Speciality materials like high frequency Rogers 4350B or flexible polyimide may raise these costs 5-10 times.

2. Complexity of Design: Complex designs result because there are complexities due to layer count, trace size/space, via specifications, and board size. It translates to more processing time and defects. A 6-layer PCB will be approximately 40% more expensive compared to a 4-layer PCB. Moreover, traces below 0.05mm will necessitate expensive LDI equipment, thus an additional 15-20% cost.

3. Order Volume and Lead Time: Smaller production volumes (1–10 prototypes) result in high costs per unit because of setup costs (e.g., making masks and programming machines). Rush orders within 24-48 hours may increase costs between 50-100 percent because of labor and shipping costs.

4. Cost After Manufacturing: The standards and testing specifications set forth by quality control (QC), for instance, IPC-6012-2 vs. IPC-6012-3, impact cost. Aerospace/military standards might raise the cost of quality control by 20-30% more as opposed to industry standards.

How Design Parameters Reduce PCB Costs: Proven Strategies by PCBCart

Design is the first-and most impactful-stage to optimize costs. PCBCart's engineering team recommends honing in on five key design parameters that can help eliminate unnecessary expense without sacrificing performance.

1. Substrate & Material Selection: Choose “Fit-for-Purpose” Options

One of the common pitfalls in the cost is over-specifying materials. PCBCart recommends matching materials to your application's actual needs, not just "best-in-class" standards:

· Substrate: FR-4 is the most cost-effective option for 90% of applications ≤1 GHz commercially. For 1 to 5 GHz signals, I-speed substrates provide a performance-cost balance that helps avoid the premium of Rogers materials, which have been necessary for RF signals or use cases at ultra-high frequencies.

· TG Value: Commonly available substrates of TG130 meet most requirements. Upgrading to TG150 or TG170 costs 3–5% or 8–10%, respectively—only upgrade to higher TG if your PCB operates in an extremely hot environment, such as automotive under-hood.

· Copper Foil Thickness: 35um (1 oz) copper is the standard for the industry in most circuits. 70um (2 oz) copper adds $10–15 per square meter and should only be used for high-current applications (e.g., power supplies).

2. Layer Count & Panelization: minimize complexity and waste

One of the most impactful cost levers is layer count, with every additional layer adding up to material, lamination, and drilling costs. PCBCart's strategies here include:

· Prioritize Even Layers: Odd-layer PCBs, for example 3-layer PCB, add 15% in processing cost to the even-layer alternatives, like 4-layer PCB, because odd lamination may cause uneven warping. Thus, when possible, prefer 4-layer boards over 3-layer or 5-layer designs.

· Optimize Panelization: PCBs should be arranged on a manufacturing panel to optimize material usage. The target material usage percentage should be ≥80% for double-sided boards and ≥75% for multi-layer boards. Use the standard V-cut spacing of 1.6mm to minimize waste. PCBCart's online panelization tool may reduce up to 15-25% of the cost for each unit of high-volume orders.

3. Trace, Via, & Solder Resist Optimization

Small design changes to traces, vias, and solder resist can avert the need for costly specialized processes:

· Trace Width/Space: Stick with standard 0.1mm+ trace widths/space; ultra-fine traces at 0.05mm require LDI equipment and add 10–15% to the cost—use them only when necessary for a high-density design, such as smartphones.

· Via Specifications: Standardize on ≥ 0.3mm via diameters. Smaller vias (≤ 0.2mm) or special types, for example, half-holes, 6mm+ PTH holes are increasing drilling time and tool wear, raising costs by 20-30%.

· Solder Resist Ink: Green ink is most cost-effective. White, black, or custom color (such as purple, transparent) requires 15% to 25% higher cost and longer lead times. PCBCart recommends green color for most of the commercial applications.

4. Surface Finish: Balance Cost vs Functionality

Surface finishes protect PCBs and ensure solderability, but costs vary widely. Cost-benefit analyses of PCBCart underline the following:

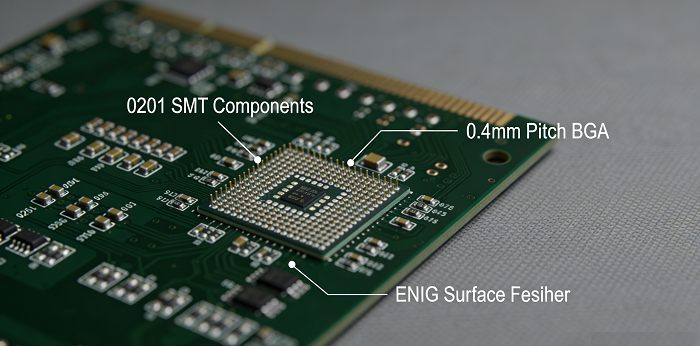

· OSP: Organic Solderability Preservative- the least expensive available, best used when not using high-frequency or small-pitch designs. Flat and compatible with automated assembly. Has 30–40% lower cost compared to immersion gold.

· HASL: This is the cheapest process for through-hole components and provides fair solderability and corrosion resistance.

· ENIG Reserve for high-reliability applications: for example, fine-pitch BGAs, RF circuits. It costs 2 to 3 times more than OSP and is not required for the majority of commercial PCBs. PCBCart Tip: Use OSP for the regular areas on mixed-component designs, and use localized immersion gold only for critical pads. This "hybrid" approach will cut the finish costs by 25% or more.

How Order Parameters Amplify Cost Savings

Beyond design, strategic order management-aligned with PCBCart's manufacturing capability-can further reduce costs.

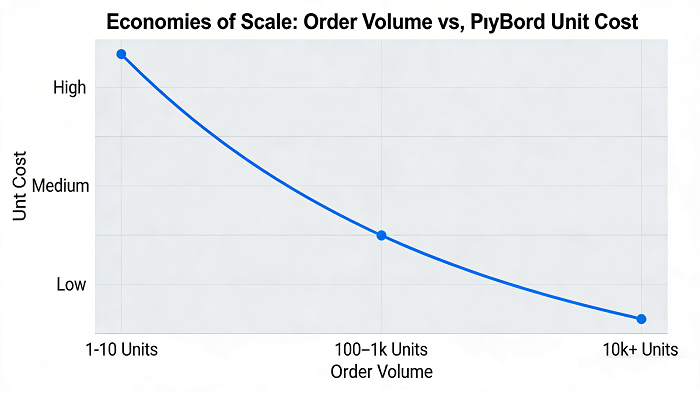

1. Leverage Economies of Scale with Order Volume

PCBCart offers volume-based pricing, with deep per-unit discounts depending on how much you're ordering:

· Prototypes (1–10 units): High setup costs drive per-unit prices up, for instance, $5 to $20 per board for a 4-layer PCB.

· Medium Volume (100–1,000 units): Setup costs are divided among more units. Per-unit prices are reduced by 40–50% from the above prices (e.g., $3–$12 per board).

· Volume High (10,000+ units): Bulk material discounts and optimized production runs enable a per-unit cost reduction of 60–70% (e.g., from $1.5–$8 per board).

2. Lengthen Lead Time to Avoid Rush Fees

Rush orders disrupt production schedules and incur premium charges. PCBCart's standard lead times-2-10 business days for most PCBs-are 30-50% less expensive than expedited, 3-5 day or rush, 24-48 hour options. By planning ahead and arranging orders to match up with PCBCart's production calendar, designers can avoid these fees altogether.

3. Right-Size Quality Control Standards

Not every PCB needs the most stringent QC. PCBCart suggests matching QC to your application:

· Commercial Grade: IPC-6012 Class 2 - for consumer electronics, IoT, and office machinery. The price is 10–20% cheaper than Class 3 products with a basic testing ratio, such as 10% of units inspected.

· High-Reliability Grade - IPC-6012 Class 3/Aerospace AS9001: for use on medical, automotive, or military PCBs. It entails 100% testing, adding about 20-30% to QC costs.

Over-testing, such as utilizing Class 3 for a simple LED PCB, is a common waste. PCBCart's QC advisors always help customers select the right standard to fit their needs.

PCBCart's End-to-End Cost Optimization Approach

At PCBCart, cost reduction is not about cutting corners—it's about engineering efficiency into every stage of the PCB lifecycle. Our approach combines:

1. Design for Manufacturability (DFM) Support: PCBCart's engineers review the client's designs free of charge to point out cost drivers such as unnecessary layers, ultra-fine traces, and the like, with suggested optimizations before the beginning of production.

2. Customized Solutions: Whether you need a prototype for a startup or high-volume PCBs for a Fortune 500 company, PCBCart tailors materials, processes, and order terms to your budget and timeline.

3. Quality Assurance: Even with cost optimization, PCBCart still follows the standards from IPC, ISO 9001, and RoHS, thus assuring reliability and compliance of your PCBs.

4. Responsiveness 24/7: Through real-time quotes, production updates, and technical support, our team minimizes any delays or unexpected costs.

Conclusion

Decoding the Costs of PCB Manufacturing: The greatest value is derived from proactive design choices and strategic management of orders. Optimizing materials, layer count, panelization, and surface finish, and aligning order volume, lead time, and QC standards with your application can reduce PCB costs by 30-50% without sacrificing quality.

At PCBCart, our cost-efficient manufacturing expertise coupled with a commitment to customer success makes us the ideal partner in optimizing your PCB budget. Whether you are designing a new product or scaling the production, contact PCBCart today and inquire how we can deliver high-quality PCBs at competitive prices starting from $0.02 per square inch for volume orders.

With PCBCart, cost optimization is not just a goal but a guarantee.

Get Quote for PCB Manufacturing

Helpful resources:

• How Much Does PCB Assembly Cost : A Complete Guide From Basics to Optimization Approaches

• Factors Influences Prices for PCB Manufacturing and Assembly

• The Surprising Secret to Designing Combination Method of PCB Panels

• The Most Comprehensive Guidelines for Surface Finish Selection

• Design for Manufacture and Assembly of PCBs and General Rules it Conforms to