Automotive have progressed from pure mechanical structure to participation of electronic parts. As early as 1970s, the average value of automotive containing electronic parts is about $100 while at the beginning of 21st century, this value has reached $1500 and it has climbed to $2000 in 2013. Now, global automotive electronics market has exceeded 150 billion dollars and the number is estimated to be over 240 billion dollars by 2020.

Furthermore, it is estimated that automotive electronic system with a market capitalization of 191 billion dollars will rocket to that with 314.4 billion dollars by 2020, with an average compound growth rate of 7.3%. A top-level automotive possibly contains 150 electronic control units that are mostly sensors and processors inside cockpit. According to some report, real value of 65% of electronic products lies in dynamical system, automotive body and chassis and most is concerned with digital power. Electronic value in electromotives will go over 70%.

Automotive containing electronic equipment are sure to apply electrical circuit board. In 2014, global automotive PCBs account for 4.6 billion dollars and this number is estimated to be over 7 billion dollars by 2020.

Application of automotive system is to increase automotive performance that up to now is displayed in three aspects:

a. Environmental improvement refers to fuel saving and exhaust reduction, that is, a process from gasoline, natural gas and biofuel to hybrid power and pure electricity. Electromobiles have become the main development trend.

b. Security increase refers to traffic accidents reduction, ranging from airbag to radar monitoring, stereo camera, night infrared monitoring, automatic collision-avoidance and automatic driving. It's estimated that self-driving automobiles will be commercialized in three years.

c. Convenience and comfort ranges from audio specific to automobiles, video and air conditioner to computer, mobile communication, Internet, navigation and electronic toll collection all of which have to be more convenient and user-friendly.

Basic Requirement of Automotive PCB

• Quality insurance requirement

Automotive PCB manufacturers should conform to regulations of ISO9001. PCBCart is fully compliant with the ISO9001:2008 quality management system and is committed to adhering to the strictest standards in manufacture and assembly.

Automotive products have their own particularities. In 1994, Ford, GM and Chrysler combined to set quality control system in automotive industry, QS9000. In the early 21st century, compatible with ISO9001 standards, a new quality control system in automotive industry was published, that is, ISO/TS16949.

ISO/TS16949 is a set of technological regulations in global automotive industry. Based on ISO9001, with special demands in automotive industry added, it focuses more on defect prevention, decreasing quality fluctuation and waste that tend to be generated in automotive component supply chain. When implementing ISO/TS16949, special attention has to be paid to primary 5 key tools: PPAP (Production Part Approval Process) regulating that products should receive customers' approval prior to volume production or after modification, APQP (Advanced Product Quality Planning) regulating that quality plan and previous quality analysis should exist before production, FMEA (Failure Mode and Effects Analysis) analyzing and coming up with measures to prevent products' potential failure, MSA (Measurement System Analysis) necessarily analyzing variation of measurement result to confirm measurement reliability, SPC (Statistical Process Control) mastering production procedure and product quality change with the application of statistical techniques. Therefore, the first step for PCB manufacturers to enter automotive electronic market lies in getting TS16949 certificate.

• Basic requirement of performance

a. High reliability

Automotive reliability primarily comes in two aspects: lifespan and environmental resistance. The former refers to the fact that normal running can be guaranteed within a lifespan while the latter refers to the fact that PCB functions remain unchanged when environment changed.

The average automobile lifespan in 1990s is in the range from 8-10 years and the present range from 10-12 years, which means that both automotive electronic system and PCB should fall within this range.

In the process of application, automobiles should withstand climate change, from extremely cold winter to hot summer, from sunlight to rain, and environment change owing to temperature rising as a result of their own running. Put it differently, automotive electronic system and PCB have to withstand multiple environmental challenges including temperature, humidity, rain, sour fog, vibration, electromagnetic interference and current surge. Additionally, since PCBs are assembled inside automobile, it is mainly influenced by temperature and humidity.

b. Light weight and miniature

Light weight and miniature of automobiles is beneficial to energy saving. Light weight derives from weight reduction of each component. For example, some metal parts are replaced by engineering plastic parts. Moreover, both automotive electronic equipment and PCB should be miniature. For example, the volume of ECU (Electronic Control Unit) applied in automobiles was approximately 1200cm3 at the beginning of 2000 while that is less than 300cm3, decreasing by four times. Plus, starting point firearm has transformed from mechanical firearm connected by wires to electronic firearm connected through flexible wires and with PCB inside, decreasing by more than 10 times in terms of volume and weight.

Light weight and miniature of PCB derive from density increasing, area shrinking, thinness and multiple layers.

Performance Attributes of Automotive PCBs

• Multiple categories of automotive PCBs

Automobiles combine machinery and electronic equipment. Modern automobile technology integrates traditional technique and advancing scientific technology, such as manual inner decorating parts and advancing GPS. In modern automobiles, there is electronic equipment with different functions at different positions and different functions derive from different types of PCBs.

According to substrate materials, automotive PCBs can be classified into two main categories: inorganic ceramic-based PCB and organic resin-based PCB. Ceramic-based PCB features high temperature resistance and excellent size stability, making it directly applied in motor system with high temperature. However, it features bad ceramic manufacturability and high cost. At present, with the development of resin substrate material in terms of its heat resistance capability, resin-based PCB has been widely applied in automobiles with substrate material with different performances applied in different positions.

Generally speaking, Flexible PCBs and Rigid PCBs are applied in normal gauges indicating vehicle speed and mileage and air conditioner equipment. Double-layer or multi-layer PCBs and Flex PCBs are used in audio and video entertainment equipment inside automobiles. For communication and wireless positioning equipment and security control equipment, multi-layer PCBs, HDI printed circuit boards and Flex PCBs are applied. When it comes to automotive motor control system and power transmission control system, special boards should be applied such as metal-base PCBs and Flex-rigid PCBs. For automobile miniature, component-embedded PCBs are applied. For example, micro processor chip is applied in power controller, directly embedded in power controller PCB. For another example, component-embedded PCB is also used in navigation equipment and stereo imaging equipment of automatic backing system.

• Different reliability requirements for PCBs at different positions

Concerned with public security, automobiles belong to high-reliability product category, so automotive PCBs have to pass some reliability tests apart from ordinary requirements such as dimension, size, mechanical and electric performance.

a. Thermal Cycling Test (TCT)

Based on five grades classified according to different positions of automobiles, PCB thermal cycling temperature is summarized in Table 1 below.

|

Positions

|

Grade

|

Low Temperature

|

High Temperature

|

|

Within cockpit

|

A

|

-40°C

|

85°C

|

|

Base shield below

|

B

|

-40°C

|

125°C

|

|

Motor

|

C

|

-40°C

|

145°C

|

|

Driving medium

|

D

|

-40°C

|

155°C

|

|

Inner motor

|

E

|

-40°C

|

165°C

|

b. Thermal shock test

Automotive PCBs are more applied in the environment with high temperature, which is especially true for Thick Copper PCBs that have to deal with external heat and self-producing heat. As a result, automotive PCBs have a higher requirement on heat resistance.

c. Temperature-Humidity Bias (THB) test

Because automotive PCBs stay in multiple environments, including rainy day or humid environment, it's quite necessary to implement THB test for them. The test condition includes the following elements: temperature (85°C), humidity (85%RH) and bias (DC 24V, 50V, 250V or 500V).

THB test has to consider CAF migration of PCBs. CAF usually takes place between adjacent vias, via and line, adjacent lines or adjacent layers, leading to insulation reduction or even short circuit. Corresponding insulation resistance depends on distance between vias, lines and layers.

Manufacturing Characteristics of Automotive PCBs

• High-frequency substrate board

Automotive collision-resistance/predictive braking safety system plays a role as a military radar device. Since automotive PCBs are responsible for transmitting microwave high-frequency signals, substrate with low dielectric loss needs to be applied with the ordinary substrate material to be PTFE. Different from FR4 material, PTFE or similar high-frequency substrate materials require special drilling speed and feeding speed during drilling.

• Thick copper PCB

Automotive electronics brings more heat energy owing to high density and power and hybrid power and electromotives tend to require more advancing electric power transmission system and more electronic functions, which leads to more requirements on heat dissipation and large current.

It's relatively easy to fabricate thick copper double-layer PCBs while it's much more difficult to fabricate thick copper multi-layer PCBs. The key point lies in thick copper image etching and thickness vacant filling.

Inner routes of thick copper multi-layer PCB are all thick copper and therefore and graphic transfer photo-induced dry film is also relatively thick, requiring extremely tremendous etch resistance. Thick copper graphic etching time will be long and etching equipment and technical condition in the best state so as to ensure complete routings of thick copper. When it comes to external thick copper routing manufacturing, combination can be first applied between copper foil with relatively thick lamination and graphic plating thick copper layer and then comes film voidance etching. Anti-plating dry film of graphic plating is relatively thick as well.

Surface difference is relatively large between inner conductor of thick copper multi-layer PCB and insulating substrate material and ordinary multi-layer board lamination fails to totally fill resin with cavity generated. In order to solve this problem, thin prepreg with a high content of resin should be applied as much as possible. Copper thickness of inner routings on some multi-layer PCBs is ununiform and different prepregs can be applied in areas with a large thick copper difference or a small difference.

• Component embedment

Component embedded PCBs were massively applied in mobile phones in order to increase assembly density and decrease component size, which is acquired by other electronic equipment as well. Therefore, component embedded PCBs are also applied in automotive electronic equipment.

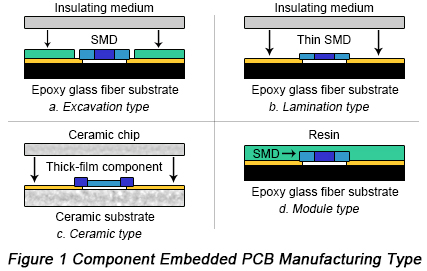

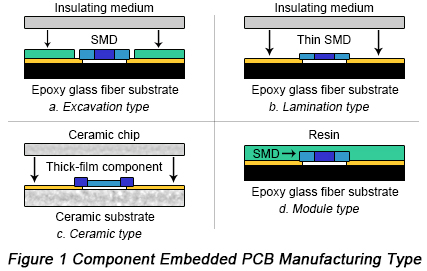

According to different component embedment methods, there are numerous manufacturing methods for component embedded PCBs. Component embedded PCBs for automotive electronics have mainly 4 manufacturing methods that are shown in Figure 1 below.

Among these manufacturing types, excavation type (Type a in Figure 1) follows the following procedure: excavation and then SMD assembly through reflow or conductive paste. Lamination type (Type b in Figure 1) is implemented through thin SMD assembly on inner circuit through reflow or refers to thin components manufacturing. Ceramic type (Type c in Figure 1) refers to thick-film component printed on ceramic substrate. Module type (Type d in Figure 1) follows the procedure: SMD assembly through reflow and resin packaging. Module type component-embedded PCBs have relatively high reliability, more suitable for automotive requirements of heat resistance, humidity resistance and vibration resistance.

• HDI technology

One of the key functions for automotive electronics lies in entertainment and communication among which smart phones and tablet PCs require HDI PCBs. Thus, technologies contained in HDI PCBs such as micro via drilling & plating and lamination positioning are applied in automotive PCB manufacturing.

Up to now, with the rapid change of automotive technologies and constant upgrading of automotive electronic functions, applications of PCBs will become multiplied. For engineers and PCB manufacturers, their attention must be paid to new technology and new content so that they are capable of meeting higher automotive requirements. As one of the leading PCB manufacturers in the world, PCBCart is fully ready to provide automotive PCBs with high density and creativity in order to be contributive to the development of automobile industry.