Industry: Medical & Life Science Instrument

Company: Confidential

Services: PCB Prototype, PCB Fabrication, Turnkey Assembly

Background

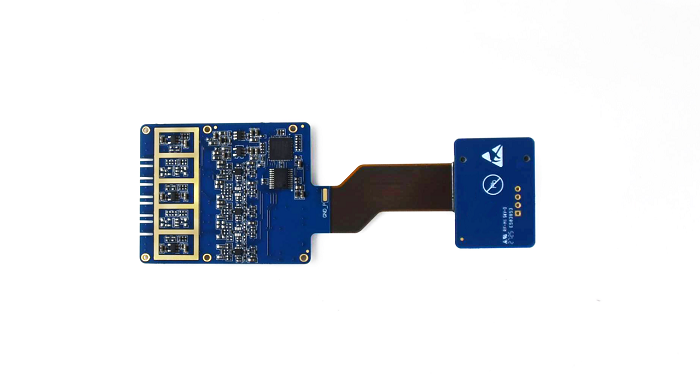

A leading developer of high-precision life science and medical instruments required a manufacturing partner for a critical component in their new optical detection system. The project was designed to support a cell detection instrument.

Given the application, the client’s requirements were stringent. The board demanded exceptional manufacturing precision, absolute reliability, and strict compliance with medical industry standards.

One key challenge is to produce a robust rigid-flex structure with no delamination. Additionally, there is a need to ensure perfectly flat surfaces for component mounting using advanced via-in-pad techniques.

At the same time, full traceability must be guaranteed with mandatory UL certification.

Hence, PCBcart was selected to provide a full suite of services, from prototype to turnkey assembly, to meet these exacting needs.

Challenges and PCBCart's Solutions

Complex Structure and High-Reliability Materials

Challenge: Needed a 6-layer rigid-flex PCB for flexible routing and reliable connections.

Solution: PCBCart chose high-performance materials compliant with 94V0 standards, ensuring secure bonds with precise adhesive control, achieving correct thicknesses of 0.25mm (flexible) and 1.6mm (rigid).

Precision Processes and Medical-Grade Standards

Challenge: Require flawless PCBs for medical devices.

Solution: Applied ENIG for solderability and reliability. Employed VIPPO for mechanical strength and surface planarity. Met high-density requirements with trace widths ≥4mil and hole sizes ≥0.254mm, ensuring compliance with markings and certifications.

Stringent Quality Control

Challenge: Zero error tolerance in medical PCBs.

Solution: Followed IPC-A-600 Class 2 standards with thorough quality checks from materials to final tests. Ensured durability of blue solder masks and white silkscreens under harsh conditions.

Technique and Parameter Requirements

To successfully manufacture the board, PCBcart implemented a series of advanced processes and adhered to the following key specifications:

| Parameter | Specification |

| Substrate | TU862 HF (standard), halogen-free |

| Flammability | 94V-0 |

| TG | 170°C |

| Finished Thickness | Rigid: 1.6mm, Flex: 0.25mm |

| Layers | 6 |

| Finished Copper | 1 oz |

| Surface Finish | ENIG |

| Via Processing | Resin Plugged Via-in-Pad |

| Solder Mask | Printed, Blue |

| Silkscreen | Printed, White |

| Min Trace/Space | ≥ 4 mil |

| Min Hole Size | ≥ 0.254 mm |

| Board Size | 45.128×125.13 mm |

| Panelization | No |

| Lead-Free Markings | Yes |

| UL + Logo | Yes |

| Date/Production Code | Yes |

| Acceptance | IPC Class 2 |

The most critical technical requirement was the resin-plugged and planarized via-in-pad process. This technique creates a perfectly flat surface, allowing sensitive components to be mounted directly over vias without the risk of solder voids or component tilting, which was essential for the project’s performance.

Customer Testimonial

"For our medical instrumentation, there is no room for error. PCBcart demonstrated a deep understanding of our requirements from the start. The quality of the rigid-flex boards was outstanding—the via-in-pad surfaces were perfectly flat, and the flex sections were robust with clean, burr-free edges. Their ability to meet the UL certification and IPC Class 2 standards was critical for our regulatory compliance. The final product integrated flawlessly into our turnkey assembly line, saving us valuable time and resources."

— Senior Hardware Engineer, Confidential Medical Client

Core Advantages of PCBCart's Medical PCBA Services

Industry Compliance Expertise: Thorough knowledge of medical standards like ISO 13485 and IPC ensures total compliance from design to production.

Advanced Manufacturing Capabilities: Equipped to handle rigid-flex PCBs, HDI, and specialty materials with advanced technology and processes.

Lifecycle Quality Assurance: Provides closed-loop quality management, including design review and traceable production, ensuring reliable Device History Records (DHR).

Customer-Centric Collaboration: Offers expert engineering support, quickly accommodates special requests, and consistently meets clients' specifications throughout production.

Advanced PCB & Assembly Solutions for Medical & Life Sciences

PCBCart's capability to meet the most exacting specifications in the medical and life science instrumentation industry. Furthermore, we expertly handle from complex rigid-flex construction to critical resin-plugged via-in-pad processing. That precision and reliability are essential for all your life science applications.

Backed by over two decades of experience, PCBCart is a trusted PCB assembly supplier. We deliver high-end service, unparalleled precision, and strict compliance (UL Certified, IPC Class 2/3) for your mission-critical applications.

Don't compromise the reliability of your next device. Partner with our experts.

Contact PCBCart today to discuss your advanced PCB requirements, or just upload your Gerber files now to receive a comprehensive, no-obligation quote and begin building with total confidence.