With the ever-evolving world of today, the demand for compact, agile, and high-performance electronic devices continues to increase. This demand necessitates the need for intelligent circuit board designs that are able to fit an array of components into compact footprints without compromise on performance or reliability. Mixed PCB assembly, bringing the best of Surface Mount Technology (SMT) and Through-Hole Technology (THT), is now an imperative step to cater to these evolving needs. This article discusses the advantages of mixed assembly and its relevance in modern electronic manufacturing, and illustrate why it's an essential part of today's technological advancement.

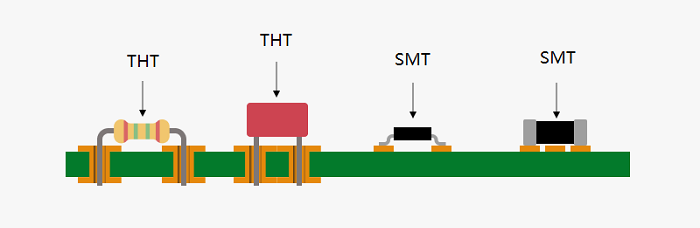

Mixed PCB Assembly refers to the blending of SMT and THT on a single board. SMT allows for components to be mounted directly on the surface of the PCB, offering precision advantage and speed advantage. THT is accomplished by passing component leads through pre-drilled holes, providing robust mechanical connections appropriate for high-stress or heat-resistant applications. Through the integration of these two technologies, producers can utilize each's exclusive benefit, and thus have greater versatility and functionality in their PCB designs.

Advantages of Mixed Assembly

Enhanced Reliability and Performance

The most impressive advantage of mixed assembly is its enhanced reliability and performance. SMT technology provides high accuracy and is perfectly capable of creating compact, lightweight designs with applications in high-density environments. Conversely, THT offers increased endurance, with consistent mechanical bonds. Together, they offer a PCB that can withstand mechanical and complex electrical requirements, and hence are appropriate for high-end devices such as industrial controllers and high-speed communication devices.

Greater Component Selection

Through the employment of mixed assembly, the component selection for manufacturers increases. While most components are preferred or dedicated in THT based on their size or functionality, others are better placed to be utilized in SMT. Having flexibility provides engineers with the ability to select a suitable component that is tailored for each job, hence maximizing the performance and capability of the final product.

Enhanced Production Efficiency

Mixed assembly simplifies the production process. With automation, the SMT and THT processes are integrated seamlessly without any downtime or transition time for switching the various assembly stages. This increases the throughput and lowers the optimum utilization of resources—most critical drivers in reducing cost-cutting in production and time-to-market.

Lightweight designs and Precision

One of SMT's hallmark features is the fact that it can position incredibly small components with great precision. This enables designers to create weight-reducing designs that save space while enhancing device mobility without sacrificing reliability on account of THT's good contacts for heavy, stress parts.

Increased Design Flexibility

Mixed PCB assemblies offer great design flexibility, making them suitable to be employed within a broad functional requirement and design need. The applications include medical devices and automotive electronics among other uses in addition to communication equipment and consumer products where mixed assemblies offer the extent of customization to satisfy some consumer and industry requirements.

Easy DFA and DFM Processes

Design for manufacturability (DFM) and design for assembly (DFA) will be far-reaching in maximizing production efficiencies. With a minimized number of parts, idealized component placement, and alignment, mixed assembly processes decrease the level of fabrication and assembly complexity, leading to faster turnaround time and reduced possibility of assembly error.

Applications of Mixed PCB Assembly

Because of the aforementioned advantages, mixed PCB assemblies are common across many high-tech applications. Some of them include:

Central Processing Units (CPUs): Mixed assemblies are employed to their full extent in handling the complex circuitry needed for fast processing.

IoT Devices: With the spread of IoT technologies, mixed assemblies provide the size and functionality needed for sensor boards and control devices.

Communication Hardware: Smartphones and accessories belong to this class, where smallness and toughness are needed.

LED and Lighting Products: The fast performance and dependability of mixed PCBs suit long-lived lighting applications.

Design Considerations for Mixed Assembly

Even though the benefits of mixed PCB assembly are numerous, proper implementation is contingent upon sound design considerations. One must perform proper design for assembly (DFA) analysis in order to foretell problems ahead of time. Some important factors include:

Component Types and Placement: One must be aware of what components are better suited for SMT or THT. The automated and manual placement options have to be studied in light of production size and precision needs.

Design Requirements: Having the same components on the same side, locating heavy components away from edges of the board, and cautious weight placement are critical to structural performance and integrity.

By solving these problems up front, manufacturers can have assembled PCBs mixed to fulfill their design requirements efficiently and effectively.

Mixed PCB assembly is a leading technological innovation in the electronics manufacturing sector. Through exploiting the respective strengths of both SMT and THT, electronics producers are able to produce more efficient, dependable, and adaptable products. Such a combined approach not only meets the current demands for high-performance and space-efficient electronic products but also opens up avenues for future technological developments. At PCBCart, we're dedicated to providing tailored mixed assembly solutions, so that our clients receive high-quality, reliable PCBs that meet their specific needs, enabling success in a wide range of industries. As technology advances, mixed assembly will definitely be leading the way towards the future of electronics.

Request Your Mixed Assembly Quote Now for Quality Solutions

Helpful Resources

• Printed Circuit Boards Assembly (PCBA) Process

• A Comprehensive Introduction of PCBA

• How to Evaluate PCB Assembly Houses?

• Turnkey PCB Assembly (PCBA) Service With Multiple Value-added Options

• Manufacturing Capabilities Between PCB Prototype Service and Custom PCB Fabrication