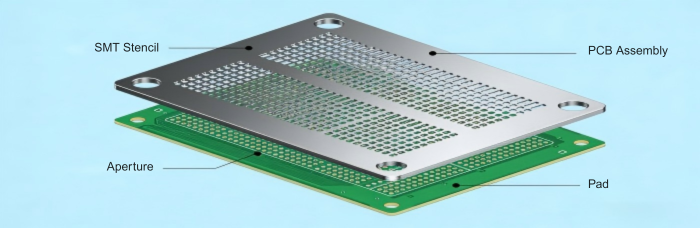

Accuracy in PCB (Printed Circuit Board) assembly is extremely important in the dynamic electronics manufacturing industry. The core of this accuracy constitutes the control of SMT (Surface Mount Technology) stencils which are important tools that determine the effectiveness of solder paste application process. Correct maintenance and care of these stencils do not only lead to improved quality of production, but also increases the life of the stencil used, saves up on wastage of material used and also optimizes on the over-all efficiency of manufacturing operations.

The Importance of Critical Role of SMT Stencils

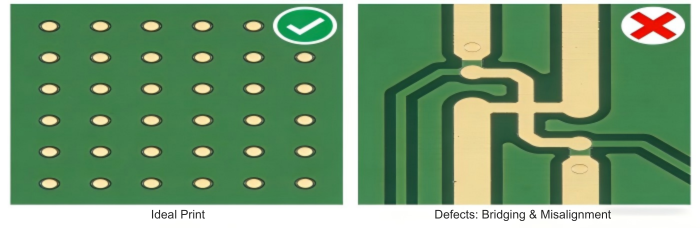

SMT stencils are very thin stencils, typically produced out of stainless steel or nickel, with carefully cut holes that can be positioned to match PCB designs. These holes allow the solder paste to be placed correctly on the PCB pads, and the components are placed correctly. Considering their critical position in the assembly line, their stencil integrity is very important to prevent prevalent defects like misalignments, bad solder joints, and bridging.

Critical Strategies to Best Stencil Care

Extensive Cleaning Processes

Constant and Automated Washing: Stencil cleanliness is the foundation of the high-quality printing. Stencils must be well cleaned after use to eliminate solder paste and blockages of apertures. In the case of manual cleaning, use non-abrasive wipes, together with a suitable solvent such as high-purity isopropyl alcohol. Automated cleaning systems are priceless in high volume operations. These systems are effective in cleaning stencils and they include wet and dry processes, which are effective in cleaning the stencils and reducing the amount of human error.

Ultrasonic Cleaning: In stencils with complex patterns, the ultrasonic cleaning systems can offer an extremely high level of cleanliness without harming the stencil. These are operated using sound waves to cleanse microscopic particles out of holes so as to preserve the crystal clear condition required in operation in fine pitch applications.

Optimal Storage Techniques

Correct Environmental Conditions: Stencils should be stored in a flat or vertical position in special racks where there is very little physical contact with them, so that they are not deformed. In order to avoid corrosion and physical distortion, a clean, dry and temperature controlled environment is necessary preferably with humidity content that is less than 50%.

Protective Measures: Protective sleeves or cases should be used to protect stencils against dust and other accidental scratches. These protective features play an important role in maintaining aperture integrity and the maintenance of consistent performance in printing.

Regular Check-up and Service

Systematic Inspection Regimes: This is a systematic method to inspect the stencils, in order to check any form of wear and tear like scratches, dents or blocked apertures. Inspections can be done using a magnification to find defects that would have otherwise not been detected. The independent maintenance of stren-condition logs such as utilized frequency and detected problems can be used to facilitate active maintenance and have the right stencils repaired or replaced at the appropriate time without disrupting production processes.

Periodic Cleanup: Other than the regular cleaning, have periodic maintenance checks. This may involve thorough cleaning or professional repair to keep the stencil at its best which is particularly needed with multi-layer stencils or more complex stencils.

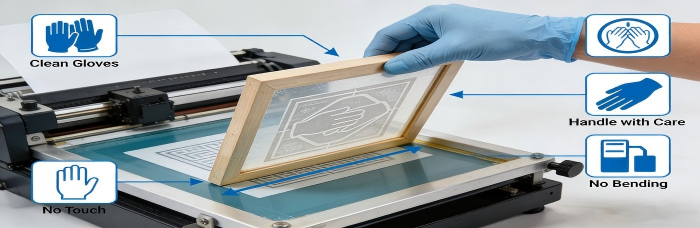

Practices of Catholic Handling

Minimal Physical Stress: Stencils should be treated carefully with clean gloves and the proper tools in order to prevent contamination or other mechanical damages. When setting up and dismantling the printing, place as little pressure as possible to avoid bending or misalignment. They can also minimize the chances of destroying these fragile tools by using special handles or frames.

Training and Protocols: The personnel should be well trained on how to handle the procedures with special emphasis on the need to maintain stencil condition. Best practices can be reinforced among the staff including workshops or refresher courses that take place periodically.

Choosing Matching Cleaning Agents

Selection of Solvent: One has to select cleaning agents that are effective but do not damage the stencil material. Isopropyl alcohol of high purity is also commonly suggested, although it is important to make sure that the solvent selected is safe to use on a certain material composition of the stencil to prevent corrosion or degradation.

Advanced Techniques of Sustained Stencil Performance

In addition to standard cleaning and inspection, more sophisticated maintenance procedures will help to increase the lifetime of stencils dramatically. More comprehensive levels of the cleanliness, which are required in precision-intensive operations, can be achieved with the use of automated systems, which involve ultrasonic or advanced solvent cleaning.

Effects of Optimal Stencil Care on Production Quality

Investment in extensive SMT stencil maintenance has significant advantages:

Improved Quality of Print: With clean aperture and integrity of stencil, manufacturers can have more accurate solder paste deposition, minimizing chances of defects and rework.

Cost Efficiency: Long life span of stencils results in less stencil replacement and reduced material waste, which will be translated to actual cost savings in the long run.

Enhanced Production Efficiency: Stable production guarantees reduced downtime due to stencil problems, and seamlessly facilitates production schedules and increases throughput.

The accuracy in the PCB assembly is directly related to the successful management of SMT stencils in the dynamic world of electronics manufacturing. They are important tools used to ensure the accurate application of solder paste hence care and maintenance is very essential in ensuring high production standards. Manufacturers can greatly improve their rates of working efficiency by using elaborate approaches that imply overall cleaning, optimum storage, frequent checking, and proper handling of activities. With the preservation of the integrity of the stencils, not only the lifespan of the tools will be extended, but the waste levels and the total costs of production will also reduce. These best practices will guarantee the process of manufacturing is healthy and serves the changing demands of technology and production perfection.

At PCBCart, we know that SMT stencils are very vital in your manufacturing success. We believe in quality and accuracy and offer a range of PCB assembly services that are unparalleled to the rest of the world and are designed for your exact requirements. Being a company that prioritizes innovation and pays close attention to detail, PCBCart is able to both provide high-quality products but also provide industry-leading tips on how to streamline your assembly processes. Request a quote and learn more about how our solutions can take your production to the next level and how your projects will reach the highest level of quality and efficiency.

Request for High-Quality SMT Stencil Quote Now

Helpful Resources

• Stencil Design Requirement on QFN Components

• How to Solve Solder Joint Problems in SMT Processing

• Process Control Measures to Stop Defects in SMT Assembly

• PCB Cleaning

• Automated Optical Inspection (AOI)