Printed Circuit Boards (PCBs) can be considered the workhorse in the electronic device world, the medium through which the complex circuitry of modern technology is driven. The needs of electronic equipment are changing as are the needs of the devices themselves. One of the most interesting technologies in this sphere is a Black Core FR4 PCB that is characterized by the original material composition and its performance features.

What is Black Core FR4 PCB?

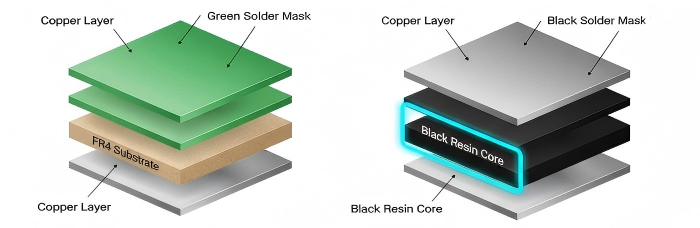

Black Core FR4 PCB is just a form of the classical FR4 board with the only difference being the presence of a specific thermoset resin layer between two copper foils. This resin does not only give the board a unique appearance but it also contributes a lot of heat dissipation to the board. The traditional FR4 is also characterized by very good performance, however, the Black Core variant takes it to the next level as it has a better thermal management which is especially appropriate in the case of high-power applications.

What is Black Core FR4 PCB?

A number of factors are taken into consideration when coming up with Black Core FR4 PCBs such that their benefits are as followed:

Material Compatibility: Coefficient of thermal expansion (CTE) is one of the first factors. The black resin core is designed to match the CTE of copper closely, which reduces the stress of a thermal cycle. This compatibility aids in avoiding the collapse of the structures guaranteeing that PCB remains intact even during different temperatures.

Power Distribution: Black Core FR4 PCBs are made with the intention of distributing power all over the board as it has high thermal properties. This consistency eliminates the problem of hotspots, one of the limiting factors in high-power circuits, further increasing the life and stability of the board.

Signal Transmission: The low dielectric constant of the core is a very important aspect as it guarantees stability and efficiency of signal transmission. The property reduces signal loss, which is necessary in a situation where accuracy and consistency in data flow is needed in terms of thermal conditions.

Good Thermal Conductivity: The thermal conductivity of the black core is the key element in effective heat management and therefore these PCBs are suitable where the heat management is important in ensuring performance and service life.

Benefits of Black Core FR4 PCBs

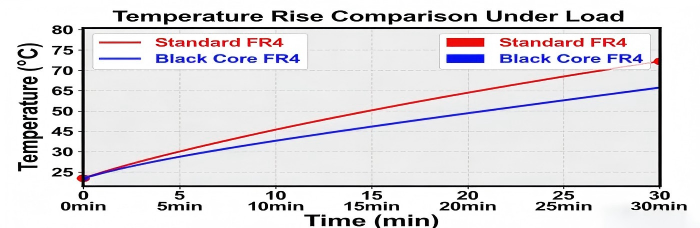

Better Heat Dissipation: This is because of better heat dissipation an advantage of Black Core FR4 PCBs. The black thermoset resin is thermally conducting in nature meaning that it is very effective at moving heat off the important components. This is important in high power electronics, where the stability of temperature can have a direct effect on performance and reliability.

Durability and Longevity: The black resin core adds to the robust and strong PCB structure that can withstand severe thermal conditions without crack formation. This is essential in harsh conditions where the devices will be resistant to failure even when they are used in severe conditions.

Improved Signal Conduction: Black Core FR4 PCB has a low and constant dielectric constant that enables better signal conduction. These boards have a low signal degradation and are especially used in high frequency applications where the fidelity of transmission of data that is transferred is the main concern.

Aesthetic Appeal: Black Core FR4 PCBs has a sleek, modern look that provides the visual sophistication to the consumer electronics. Black color offers a non-reflective surface, which hides copper traces and adds a well-decorative look to the entire device and thus should be a preferred choice when aesthetics of internal components is important to the products.

Applications of Black Core FR4 PCBs

Black Core FR4 PCBs have applications in the following ways:

Automotive Electronics: These PCBs suit automotive structures such as infotainment and control dashboard, where thermal control and appearance fusion is necessary.

Consumer Electronics: Black core PCBs would be appropriate in devices such as smartphones and tablets that combine the two advantages of looks and functionality.

LED and Lighting Equipment: Black Core FR4 enhances the performance of LEDs by boosting the heat dissipation and minimizing of light reflections essential in contrast and efficiency in lighting applications.

Gaming and Entertainment Systems: Black Core PCBs are aesthetically designed and upgraded to give gamers and other entertainment devices a new look and feel.

Manufacturing Process

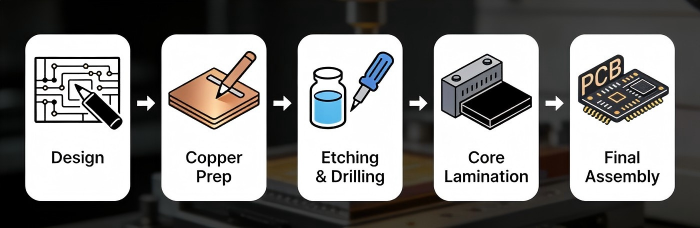

The workflow of developing Black Core FR4 PCBs is similar to the traditional manufacturing of PCBs with several specific modifications that are associated with the incorporation of the black resin core:

Design and Layout: Preliminary designs are designed in PCB design program and then printed on a clear film.

Copper Board Preparation: The copper board is carefully cleaned and the transfer of the design is done with controlled heat and pressure to create accuracy.

Etching and Drilling: The copper is etched away, and components and vias holes drilled.

Core Integration: The core resin is black and is laminated between the copper layers where pressure and heat are used to create a solid bond.

Final Assembly: A solder mask is used to cover copper traces, and silkscreening is used to add labels and identification to components, and the final step in the production process is complete.

Black Core FR4 PCBs are a major breakthrough in the PCB technology which has the greatest benefits in thermal management and the looks. Electronic devices are being used with more and more complex components, both in terms of functionality and aesthetics, so Black Core FR4 PCBs are one of the innovative solutions. Their distinctive features are applicable to the wide spectrum of applications, and they will possible increase its performance and durability and possess a smooth look which will be in line with the newest requirements of the electronics.

PCBCart is the leader in PCB production with exceptional skills and accuracy in producing high quality black core FR4 PCBs. We have advanced facilities and a highly qualified team, so that we can ensure every PCB is carefully designed to suit your needs. In the development of the latest consumer electronics or hardy automotive systems, we are ready to offer customized solutions that are to improve performance and design. Request a quote from PCBCart now and move your electronic products to the next level.

Request for Black Core PCB Assembly & Fabrication Quote

Helpful Resources

• FR4 Copper Clad Laminates

• High-Frequency PCB Design Guidelines

• PCB Manufacturing Process — A Step-by-Step Guide

• LED PCB Design and Quality Control