The ever-changing world of electronic products sees the tools we use in circuit designs, testing, and implementation play a crucial role in the efficiency and resulting success of the product. Among the most essential tools in this field are Printed Circuit Boards (PCBs) and breadboards. Both have their own distinct set of characteristics, features, benefits, and drawbacks, each designed to serve differently in the process of electronic designs. This article will serve to give you a detailed comparison between the two tools.

What Are PCBs and Breadboards?

On one level, the purposes of PCBs and breadboards are the same: they are both platforms. However, their needs differ greatly.

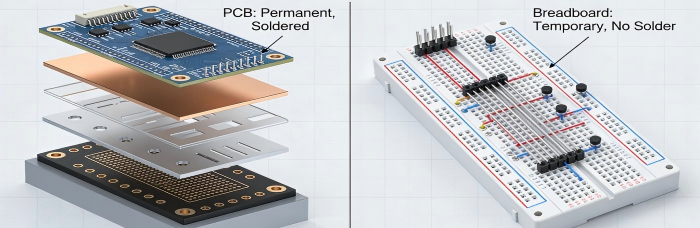

Printed Circuit Boards, or PCBs, are the backbone of modern electronics. They consist of a non-conductive substrate-usually fiberglass-with etched copper traces that form circuits and hence electrically connect components. Designs for a PCB are normally done with computer-aided design software in which every line and pad has to be well planned for efficiency and reliability. Fabricated and designed, the PCBs then become permanent fixtures in their respective electronic devices, hence ideal for mass production and commercial use.

However, breadboards are temporary platforms used for prototyping and educational purposes. They consist of plastic arrays of holes into which components and wires can readily be inserted and rearranged. These openings connect with metal strips underneath, by which quick changes can be made without soldering. This characteristic has made the use of breadboards a popular choice for students, hobbyists, and engineers in the incubatory stages of a design process where much experimentation and iteration need to take place.

Comparison Analysis: PCB vs. Breadboard

An understanding of differences between PCBs & Breadboards requires discussion of several key points ranging from design & construction to robustness & complexity levels.

Design Philosophy and Application

PCB boards are meant to be permanent. Each element of the circuit is soldered on the circuit board, with traces placed on the circuit board in a strategic manner so that the circuit works at its best.

Breadboards, on the other hand, are designed in a way that takes into account flexibility. One can test circuit ideas using breadboards. The idea here is to provide a prototyping or experimental platform to work with circuits without finally settling on a design.

Complexitiy and Precision

PCBs have the competence to deal with complex circuits, with accurate placement of components as well as routing. Multi-layer PCBs support complex designs with many paths, which is essential in contemporary electronics to achieve compact design with high density.

Breadboards are to be used for simple to moderately complex circuits. The circuit complexity is restricted by their design. They are not to be used for circuits requiring strict electronic properties such as low inductance and capacitance values.

Durability and Environmental Stability

Printed circuit boards are designed to last. Constructed of durable materials, they can resist environmental stresses from moisture or temperature swings that can affect their long-term stability and durability.

The breadboards are not that resilient. They are not designed to last or be used under very harsh conditions. In time, some of those connections start to loosen, and the prototype may not be as reliable anymore.

Agility and Iteration

Among all, the most important disadvantages of PCBs are: PCBs have very limited flexibility once fabricated. Design changes also require a new layout and manufacturing process, which can be rather time-consuming and costly.

Breadboards are designed for flexibility. They let the designer quickly test various configurations and make changes on the fly, which is very important in the development cycles during the prototyping phase.

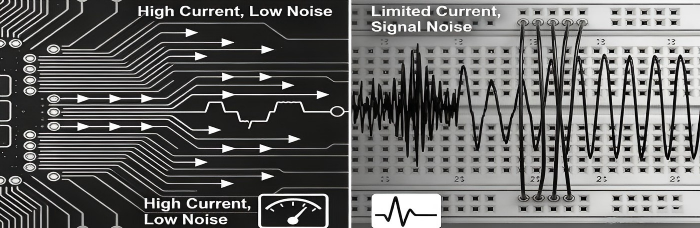

Electrical Performance & Capacity

PCBs offer better electrical properties. PCBs have the ability to conduct larger currents and are compatible with high-speed signals with less electrical noise. PCBs possess better electrical properties compared to other boards as they can carry larger currents and are suitable for demanding applications.

A breadboard has a limited current-carrying capacity. A breadboard is not appropriate for a high power circuit and may introduce noise to the signal due to the loose and resistive connections provided by the breadboard.

Scalability & Mass Production

PCBs are scalable to perfection. Once a plan works, you can reproduce it en masse, and this helps in scaling. The use of breadboards is not scalable. The original intent of using breadboards is to easily create prototypes.

When to Use Breadboards and PCBs

Whether to use the PCB or the Breadboard in your electronics project depends on the current phase the project and the needs of the project:

Employ a Breadboard: A breadboard is the best tool that can be used during the design stage, especially where testing, learning, and making modifications quickly are of utmost importance. This is especially useful in the classroom setup.

Transition to a PCB: Noticing a need for a level of permanence or mass production capabilities within a design, it is essential to transition to a PCB build. A PCB is essential once you have completed a prototyped build and are working towards commercialization or requiring a level of precision and robustness with the design that a PCB can guarantee.

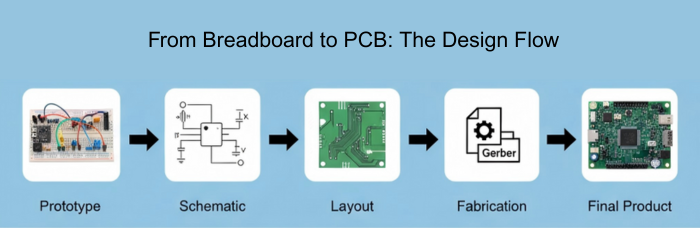

Turning a Breadboard Design into a PCB

Translation from a breadboard prototype to a PCB involves making an intensive schematic for the working design and then using CAD software to route the copper traces, positioning of components, and layers that your PCB will require. Once this is done, a PCB designer creates Gerber files that instruct the fabrication process. The interaction with a qualified PCB manufacturer means that the final board will meet all the specifications in the design and quality fronts.

Both PCBs and breadboards are of great importance in the realm of circuit design, each suited for various needs and project phases. While breadboards are used to offer rapid prototyping and flexibility during the exploration and learning phases, PCBs are what a finished product requires for stability and precision. Understanding when and how to use each tool is critical in the development of reliable, high-quality electronic devices. Designers can leverage both breadboards and PCBs to innovate efficiently, easily moving from concept to a finished product.

When you move on from using the breadboard for your electronic designs to using the PCB, selecting the correct manufacturing service provider becomes equally important. PCBCart is your one-stop solution for top-notch PCB manufacturing services that meet your specific project requirements. Backed with advanced technology, strong emphasis on accuracy, and extensive expertise across multiple industries, we can ensure that all your electronic design conversions are accomplished with the highest levels of efficiency and reliability. Feel free to experience our services and see how we can help you turn your electronic design ideas into tangible reality.

Request for High-Quality PCB Fabrication & Assembly Quote

Helpful Resources

• PCB Prototyping Process

• Multilayer PCB Benefits and Applications

• A Beginner’s Quick Guide to PCB Layout

• How to Evaluate A PCB Manufacturer