In the world of electronics manufacturing, the leap from prototyping into High-Volume Manufacturing is another important inflection point. While the prototyping stage focuses on functionality and speed to market, the core tenets of mass production revolve around efficiency, consistency, and-most critically-cost control. For production runs of over 10,000 units, savings of a few cents at a single solder joint or component can result in hundreds of thousands of dollars of profit derived from economies of scale.

Cost optimization in PCBA does not just involve negotiating for lower material prices but is a holistic discipline that integrates engineering design, supply chain management, and manufacturing processes. Here are actionable strategies for cost optimization in a high-volume environment.

Deconstructing the Cost Structure

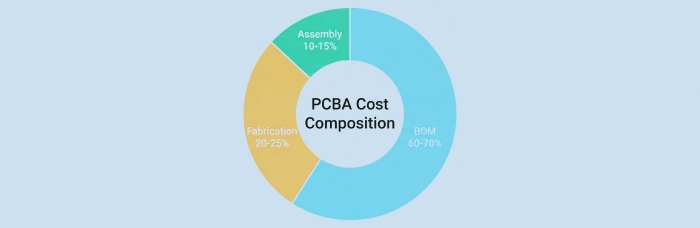

Understanding cost composition is central to any meaningful cost reduction. The price of a PCBA is typically driven by three factors:

Bill of Materials (BOM) Cost: This usually takes 60-70% of the total cost. In mass production, high-end ICs or connectors with a single source often set a "price floor" which is difficult to negotiate.

PCB Fabrication: Layer count is the most important cost multiplier. Moving from a 4-layer to a 6-layer board can raise the cost of a bare board by 30-50%. Also, special processes such as HDI or blind/buried vias greatly inflate the cost of manufacturing.

Assembly and Labor: SMT is highly automated and cost-effective, while THT uses either manual insertion or specialized pallets for the placement, making it both inefficient and expensive.

Design for Manufacturing (DFM)

The most impactful cost reductions occur before the first board is ever produced. DFM principles need to be implemented during the design phase itself.

Reducing Complexity and Layer Count

Engineers should avoid "over-engineering" vigorously. By optimizing component layout and routing logic in concert, reduce layer counts where possible; for example, optimizing a 6-layer design down to 4 layers. In consumer electronics products, unless space is extremely limited, expensive HDI processes can be avoided. Often, it is cheaper to increase the board dimensions slightly to support standard routing technology than to reduce the size of the board and hence require expensive micro-vias.

BOM Normalization and Standardization

A bloated BOM is a silent profit killer. Mass production designs should be based on the principle of "Normalization":

Reduce Line Items: If a design uses both 10kΩ and 10.2kΩ resistors, and the tolerance allows, standardize them to 10kΩ. This can reduce the number of feeder slots required on the pick-and-place machine, which reduces setup and changeover time.

Prioritize SMD: Whenever possible, avoid through-hole components in favor of Surface Mount Devices. Fully automated SMT lines can place tens of thousands of components per hour, whereas manual insertion is much slower and introduces quality risks.

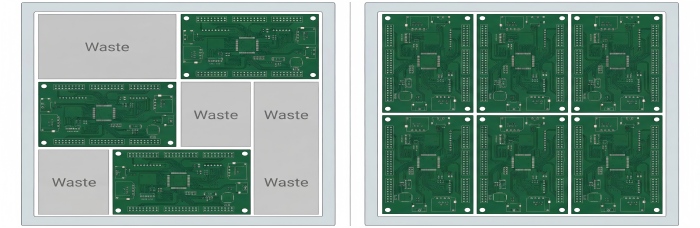

Panelization Efficiency

In high-volume production, the PCBs are manufactured in "panels." The designers need to calculate the panel utilization rates to minimize the waste material, the rails that occur at the edges. An optimized panel design reduces not only the laminate material costs but also increases the throughput rate of SMT equipment substantially.

Supply Chain Management

Supply chain strategy is equally as important to engineering design in a world of constant component volatility.

Economic Order Quantity: Utilize the volume of mass production and find the sweet spot that effectively balances inventory holding costs with bulk discounts. To achieve this, it will be significantly cheaper to buy components in a full reel compared to purchasing cut tape.

Expand the Approved Vendor List: For mass production, it is very dangerous to specify "Murata Only" in the BOM. Second Sources (2-3 different brands) of all passive components should be validated by engineers to allow the procurement team to switch to whatever is cheapest and/or available at time of need.

Localization: While overseas labor may be cheaper, for heavy or bulky products, the ocean freight and/or long transit times offset the labor savings. Priority to suppliers around the assembly factory provides for "Just-in-Time" delivery and reduces warehousing pressure.

Process Optimization and Cost of Poor Quality

Balancing Test Coverage: Though 100% functional testing is comforting, it's usually too slow for HVM. HVM should shift most of its reliance to AOI and ICT. An ICT "Bed of Nails" fixture requires an investment of several thousands of dollars upfront, but can verify a circuit in a few seconds, which is much quicker than manual debugging.

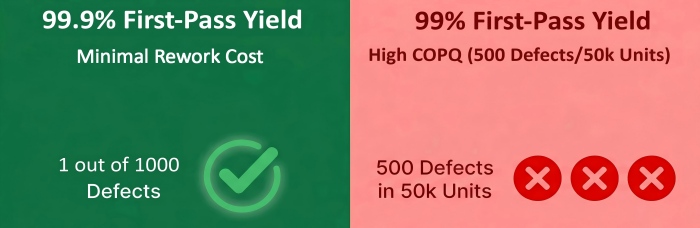

Managing "Cost of Poor Quality" (COPQ): Rework is costly. Within a production run of 50,000 units, a 1% defect rate equates to 500 failed boards. It is way cheaper to invest upfront in high-precision stencils and SPI equipment to increase first-pass yield to 99.9%, rather than employ technicians to rework defective boards later.

In sum, cost optimization for high-volume PCB assembly is a truly multidimensional effort involving cautious integration of design principles, supply chain management, and manufacturing processes. Companies can realize considerable cost savings through cost structure dissection, DFM studies, BOM normalization, and efficient panelization. Greater supply chain flexibility and investments in quality assurance processes further drive down costs while ensuring product consistency. Such strategic efforts are fundamental to competitive advantage at the scale of mass production, allowing companies to supply high-quality products at optimized costs.

PCBCart stands out as a trusted partner in this optimization journey, offering extensive industry expertise and cutting-edge manufacturing solutions. Our capabilities are designed to assist high-volume needs with advanced technologies and streamlined supply chain practices. We pay close attention to quality and efficiency, ensuring your products benefit from reduced complexities and costs. By choosing PCBCart, you align yourself with a partner committed to maximizing value in each phase of the production process. We invite you to request a quote with PCBCart today to explore how we can take high-volume PCB assembly projects to the next level with greater precision and cost-effectiveness.

Get an Instant Quote for Cost-Effective PCB Assembly

Helpful resources:

• 6 Effective Ways to Cut PCB Assembly Cost Without Sacrificing Quality

• Factors Influence Prices for PCB Manufacturing and Assembly

• SMT Assembly Process Optimization by Multi-head Gantry-Type Chip Mounter

• How to Ensure the Quality of PCBs

• Announcing a Tip to Reduce Cost and Increase Reliability of Your PCBs