Functionality and reliability are critical for Printed Circuit Boards within the dynamic world of electronics. Being the backbone of most electronic devices, PCBs have to be put through a series of rigorous tests to meet quality and performance standards. The testing of PCBs is therefore important to identify potential issues that could lead to costly failures, which may damage a company's prestige and its bottom line. This guide explores various methods used in the testing and characterization of PCBs, offering insights for engineers, manufacturers, and electronics enthusiasts.

Importance of Testing a PCB

Testing PCBs is a critical component in the manufacturing process for several reasons:

Fault Identification and Correction: Testing of the PCB helps in locating problems in design, functionality, and manufacturability. If the problems are from poor placement of components, solder joint defects, or electrical failings, proactive testing enables the designers to make the required corrections prior to large-scale production.

Time Efficiency: The earlier the errors are detected in the testing stage of the PCB, the faster the prototyping and production, hence enabling designers to quickly identify and fix problems. This contributes to faster development cycles and quicker time-to-market, an extremely crucial aspect of maintaining a lead in rapidly changing technology.

Cost Reduction: Rigorous testing of prototypes by manufacturers can help prevent the production of faulty lots, which might prove costly and wasteful. Early correction of design flaws ensures that full-scale assembly is only started once the design of the PCB is as robust as possible.

Returns and Recalls Reduction: Effective testing minimizes the chances of defective products reaching the market, thus reducing the logistical and financial burdens associated with product returns, customer dissatisfaction, and potential recalls.

Safety: Trustable testing of the assembly can avoid potential deployment of malfunctioning PCBs, thus preventing safety issues like overheating or electrical failures that can be dangerous to users and damage equipment.

Key Components Tested during PCB Testing

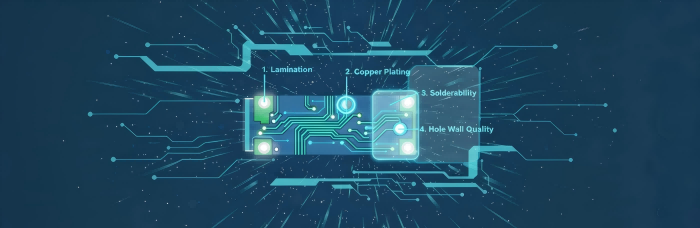

Testing on PCBs involves various evaluation areas that make sure the standards and expectations are complied with, including:

Lamination: Since the quality of the laminate is basic to durability, tests assess the resistance of the laminate to peeling or delamination under conditions of force or heat in order to ensure structural integrity.

Copper Plating: Copper layers on a PCB should possess adequate tensile strength and elongation. Tests are concentrated on these aspects to ensure conductivity along with mechanical strength.

Solderability: It concerns the ability of the board to be soldered efficiently, hence attaching the components. In many tests, wettability of the surface is checked for good, fault-free joints.

Hole Wall Quality: Checks are made to prevent cracking or other integrity failures in the plated through holes, which are critical to component connectivity.

Electrical Conductivity: The ability of the PCB to conduct electric currents with minimal leakage is a basic requirement. Ensuring conductive reliability is important for overall board performance.

Water Absorption/Resistance Tests: These are some of the most common environmental resistance tests that are carried out to simulate operating conditions. Tests are made for resistance to water absorption and cleanliness, essential for PCBs operating in humid or corrosive environments.

Key Steps of Testing a PCB

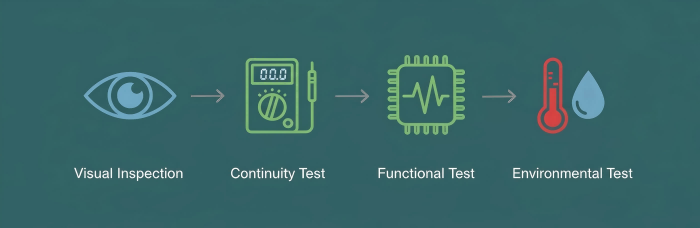

Visual Inspection

In this regard, the first step in the testing of the PCB involves its visual inspection for defects, soldering anomalies, misalignment of components, and other forms of physical damage. Magnifiers or Automatic Optical Inspection systems may be employed to identify problems that would otherwise lower its performance and reliability.

Continuity Testing

Continuity testing checks the integrity of all the electrical connections to and from the PCB by either resistance measurement or voltage drop tests, which would confirm whether any open or short circuits may hamper the functionality.

Functional Testing

Functional testing is a comprehensive evaluation of the performance of a PCB to ensure that it meets specifications. Functional testing simulates real-world scenarios in order to validate the operation of a PCB as intended.

Environmental Testing

This step gauges the robustness of the PCB in resisting several conditions, temperature fluctuations, humidity, and vibration. The testing ensures reliability in the application environment for which the PCB is meant to function in.

Common PCB Testing Methods

Automated Optical Inspection (AOI)

Advanced optics used in AOI capture images of the PCB and compare these to reference images or schematics for component misalignments, missing components, and soldering issues. AOI can be deployed on its own or in conjunction with other methods to increase coverage and enhance defect detection.

X-ray inspection is a non-destructive method that detects hidden defects within a PCB, using advanced X-ray technology. This technique is especially useful when it comes to the analysis of solder connections, internal traces, and component integrity in complex assemblies like multilayer boards.

ICT is an in-circuit functional test methodology that involves powering up individual circuits of the PCB and testing for failures. It has very high fault coverage, testing defects associated with solder connections, component failures, and faulty circuits. It requires very specialized and sometimes expensive equipment.

Flying Probe Testing

Suited for small to medium production volumes, this test method utilizes robotic arms to probe test points with no power applied to the unit under test. It can be adapted to a range of designs, checking for opens, shorts, resistance, capacitance, and inductance faults.

Functional Testing

Functional testing simulates the intended working environment and tests the different features, interfaces, and operations of the board to make sure everything works as expected. The test may be automated or manual depending on the complexity of the PCB design.

Burn-In Testing

Burn-in testing puts PCBs through a prolonged period of stress by imposing continuous loads on them in order to detect early failures and establish load capacity. It is an intensive test that greatly helps in ensuring the reliability of the product, especially for those highly critical applications where performance becomes a matter of prime concern.

Design Optimization for Testing of PCBs

Testability can be improved if design philosophies such as Design for Manufacturing, Design for Assembly, and Design for Test are integrated.

DFM aligns the design with manufacturing capabilities, thus avoiding most of the production problems.

DFA focuses on placing components logically to make the assembly process easier and with fewer errors.

DFT optimizes the design to make testing easier, by making critical areas accessible for fault detection.

Effective testing of PCBs is critical toward ensuring the reliability and success of an electronic product. By selecting and implementing appropriate test methodologies, manufacturers can provide better PCBs that would also satisfy both functional and quality requirements in today's challenging electronics market. Here at PCBCart, we are glad to assist you in PCB testing matters by offering customized services that will help in making your product successful, from prototype to production. Contact us to find out how we can help with your optimal PCB design and testing results.

Get an Instant Quote for High-Quality PCB Assembly

Helpful resources:

• How to Implement Quality Inspection of PCBs

• PCB Manufacturing Process — A Step-by-Step Guide

• Short Answers to Big Questions about PCB Design (Testing Section)