In today's technology era, the smooth operation of electronic equipment is based on reliable connections facilitated by PCB gold fingers. These critical components, located on the edge of printed circuit boards, ensure perfect connectivity between various electronic modules, from computers and cell phones to sophisticated industrial machineries. This article talks about the importance, manufacturing process, types, applications, and design considerations related to PCB gold fingers.

What Are PCB Gold Fingers?

PCB gold fingers are the gold-plated contact areas on the edges of a printed circuit board (PCB). They serve as vital connectors, attaching to matching slots on motherboards and peripherals, such as graphics and sound cards. This link makes it possible for electrical signals to pass through, enabling commands to be performed and making the different devices cooperate.

The choice of gold as the plating finish is not an accident. Ideal for its conductivity, resistance to corrosion, and durability, gold ensures that such contacts perform equally well after multiple mechanical use as they did when they were brand new. That is why gold plating remains the standard, even though it is more expensive than other finishes like copper or nickel.

Types of Gold Finishes

The operation of gold fingers relies on the type of gold finish used, which can be categorized generally into:

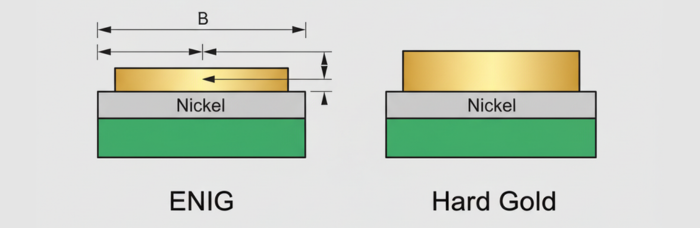

Electroless Nickel Immersion Gold (ENIG): ENIG is becoming more popular as it is inexpensive and simple to solder. The ENIG finish provides a reliable electrical connection that is resistant to corrosion and oxidation. The gold layer, however, is softer and thinner (2-5 microinches typically) than some other finishes and is not recommended for high-durability applications with multiple insertion and removal.

Electroplated Hard Gold: It consists of a thicker and harder surface (3-50 microinches), making it ideal for applications with high insertion cycles and regular mechanical stress. The hard gold, normally alloyed with cobalt, provides strength to provide long life without compromise in performance.

Classification of Gold Fingers

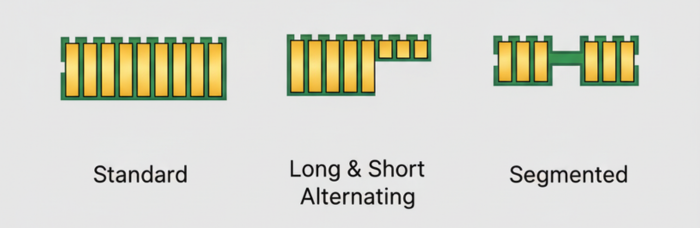

Gold fingers can be classified based on their construction and function:

Standard (Flush) Gold Fingers: Rectangular pads of equal size, closely placed along the board edge. They are utilized in network cards and graphics cards.

Long and Short (Uneven) Gold Fingers: These are connectors with pads of unequal lengths, commonly utilized in memory modules, USB flash drives, and card readers. The unequal lengths ensure proper data timing and signal integrity.

Segmented (Interrupted) Gold Fingers: With gaps or interruptions within the pads, these fingers are suited to unique signaling needs in intricate interfaces, such as those required for special data communications.

Design Specifications

Performance and reliability of the gold fingers rely on meticulous design. Engineers must adhere to strict guidelines to make these connectors function as specified:

Spacing and Placement: The gold-plated connectors should be clear of plated-through holes (PTH) to avoid interfering signals. Solder mask and screen print should not encroach into the gold fingers' area.

Chamfering and Beveling: Gold fingers should have a beveled edge, ranging from 30° to 45°, for easy insertion. This beveling allows easy connection and stability in mating slots.

Positioning: Maintain at least 1.0 mm from the PCB edge, fingers spreading from the center of the PCB, to prevent insertion alignment issues.

These specifications not being met would result in loose contact, physical destruction, or even incompatibility with the circuitry as designed, which will degrade the overall performance of the electronic device.

Manufacturing Process

Gold fingers are manufactured in various controlled processes to achieve that they meet resilient industry standards:

Nickel Plating: A nickel film (3-6 microns) is applied to the connector edges first as a barrier and adhesion layer for subsequent gold plating.

Gold Plating: Hard gold, occasionally alloyed with cobalt to enhance its durability, is plated over the nickel. Thickness depends on the application, with electroplated gold generally thicker for applications that see heavy use.

Quality Assurance: All PCBs are subjected to rigorous visual examination as well as adhesion testing, such as the tape test, to ensure the adhesion and integrity of the gold plating.

Beveling: Finally, the edges are beveled to a specified angle to facilitate easy insertion into mating connectors.

Applications of PCB Gold Fingers

Gold fingers are priceless to a wide range of electronic applications, with a standout contribution in:

Mobile Phones: Offer robust SIM card and battery terminal interfaces that can be plugged and unmounted frequently without the loss of characteristics.

Computers and Peripheral Devices: Required in memory sockets, expansion cards, and peripheral device ports. They ensure fast data transfer and secure connections to provide improved performance and reliability to the user.

Automotive Electronics: Gold fingers within automobiles connect dashboards, sound systems, and navigation components, offering resistance to vibration and temperature shifts during operation.

Home Entertainment and Office Machines: Audio-visual equipment and office peripherals like scanners and printers employ these connectors to enable round-the-clock working and high-quality output.

PCB gold fingers are crucial to maintaining reliable electronic contact between a vast array of devices. Their precise design and robust construction ensure consistent performance in a continuously changing technological landscape. At PCBCart, we take pride in producing high-quality PCBs with meticulously designed gold fingers to the stringent standards required for today's electronic uses. Whether you are designing new technology or improving current systems, PCBCart stands ready to support your PCB needs with superior quality and service. Contact us today for additional information and a quote tailored to your projects.

Request for Cost-Effective & Advanced PCB Assembly

Helpful resources:

• Plated Half-Holes (Castellated Holes) vs Gold Fingers

• PCB Side Plating — Another Edge Contact Solution

• How to Specify Gold Finger Beveling in Gerber & Fabrication Notes

• Common Gold Finger Defects and How We Prevent Them at PCBCart