In the realm of printed circuit board (PCB) manufacturing, surface finishes are far more than just protective layers—they are critical enablers of performance, reliability, and longevity. These coatings shield exposed copper traces from oxidation, ensure robust solder joints during assembly, and adapt to the unique demands of diverse electronic applications. From cost-effective workhorses to high-performance solutions tailored for precision designs, the choice of surface finish directly impacts a PCB's functionality, production costs, and suitability for its intended use. Among the most widely used options are Hot Air Solder Leveling (HASL) and Electroless Nickel Immersion Gold (ENIG), but a spectrum of alternative finishes also caters to specialized needs. This article explores the key characteristics, trade-offs, and applications of these surface treatments to guide informed decision-making in PCB design and production.

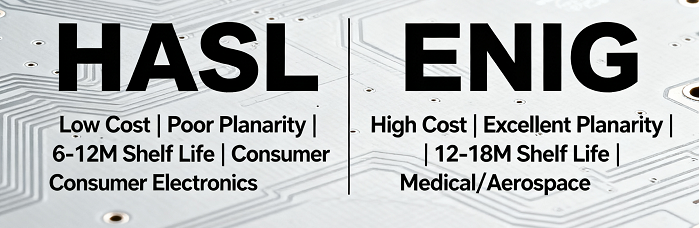

Hot Air Solder Leveling (HASL): The Cost-Effective Workhorse

HASL has long been a cornerstone of PCB manufacturing, valued for its simplicity and affordability. The process involves cleaning the PCB to remove contaminants, immersing it in a molten solder bath (either lead-tin for traditional variants or lead-free alloys like tin-silver-copper for RoHS compliance), and then using hot air knives to blow off excess solder. This creates a thin, uniform layer of solder over copper pads, forming a protective barrier against oxidation while enhancing solderability.

One of HASL's greatest strengths is its cost-effectiveness, making it ideal for high-volume production and budget-constrained projects. It offers excellent solderability across various assembly techniques—including wave soldering, reflow soldering, and hand soldering—and allows for easy rework, a valuable feature for prototyping or field repairs. HASL-finished PCBs also boast a respectable shelf life, typically 6–12 months, before solderability begins to degrade.

However, HASL has notable limitations. The hot air leveling process often results in uneven surface planarity, with slight doming on pads that can hinder component placement for fine-pitch devices (pitches below 0.5mm). Traditional leaded HASL also raises environmental concerns, though lead-free alternatives address this by complying with RoHS regulations—albeit at a slightly higher cost. Additionally, the variable solder thickness (1–50 μm) can impact electrical performance in high-frequency or impedance-controlled designs. For these reasons, HASL is best suited for applications like consumer electronics (e.g., household appliances, toys), automotive non-critical systems (e.g., infotainment), and industrial control equipment, where cost and basic reliability take precedence over precision.

Electroless Nickel Immersion Gold (ENIG): Precision for High-Performance Applications

In contrast to HASL, ENIG is a sophisticated surface finish designed for demanding, high-precision applications. Its process begins with cleaning the PCB, followed by electroless nickel deposition—a autocatalytic reaction that creates a 3–6 μm nickel layer acting as a diffusion barrier between copper and the subsequent gold coating. A thin gold layer (0.05–0.1 μm) is then applied via immersion, where gold atoms displace nickel atoms due to their higher nobility. This dual-layer structure delivers a flat, uniform surface that excels in fine-pitch and high-density designs.

ENIG's key advantages lie in its exceptional planarity, making it perfect for ball grid arrays (BGAs), chip scale packages (CSPs), and components with pitches below 0.3mm. It offers an extended shelf life of 12–18 months, as the gold layer effectively prevents nickel oxidation. ENIG is fully RoHS compliant, corrosion-resistant, and compatible with both soldering and wire bonding, making it versatile for advanced assembly processes. These traits make it the preferred choice for critical applications like aerospace and defense electronics, medical devices, high-frequency RF equipment, and high-end consumer electronics (e.g., smartphones, tablets).

Despite its performance benefits, ENIG comes with trade-offs. It is significantly more expensive than HASL, due to the use of gold and the complex chemical deposition process. A major concern is the risk of “black pad” defects—corrosion between the nickel and gold layers that can lead to solder joint failure, though modern manufacturing processes have mitigated this issue. ENIG also tends to produce more brittle solder joints and is more difficult to rework compared to HASL.

Beyond HASL and ENIG: Specialized Surface Finish Options

While HASL and ENIG dominate many applications, several other surface finishes address niche requirements, balancing performance, cost, and functionality:

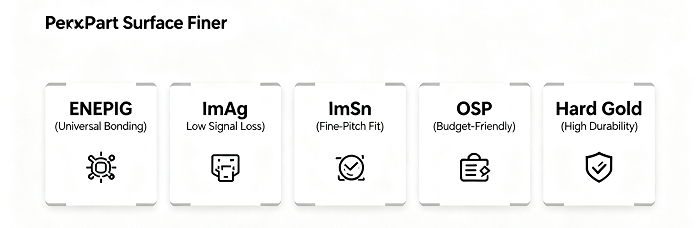

Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG)

An advanced variant of ENIG, ENEPIG adds a palladium layer between nickel and gold. This palladium layer prevents nickel oxidation and diffusion, enhancing corrosion resistance and wire bonding performance. It is a “universal” finish compatible with soldering, wire bonding, and conductive adhesives, making it ideal for complex assemblies. However, the inclusion of palladium and gold keeps it more costly than HASL and some other alternatives.

Immersion Silver (ImAg)

A cost-effective middle ground between HASL and ENIG, Immersion Silver is applied via chemical displacement, creating a thin (4–12 μm) lead-free layer. It offers good planarity, low signal loss for high-frequency applications, and RoHS compliance. However, it is prone to tarnishing and oxidation if not handled carefully, and its shelf life is shorter than ENIG's.

Immersion Tin (ImSn)

RoHS-compliant and affordable, Immersion Tin is deposited via chemical displacement (20–50 μm thickness). It excels in fine-pitch designs and press-fit applications due to its flat surface. However, it is susceptible to tin whisker formation, has a shorter shelf life, and can be damaged by improper handling.

Organic Solderability Preservative (OSP)

OSP uses a water-based organic compound to form a thin protective layer on copper pads. It is cost-effective, lead-free, and delivers a flat surface for soldering. However, it has a short shelf life, requires careful handling to avoid soldering issues, and its thickness is not easily measurable.

Hard Gold

Hard Gold consists of a gold alloy (with nickel, cobalt, or iron) plated over nickel. It is extremely durable and has a long shelf life, making it ideal for high-wear components like edge connectors, battery contacts, and keypads. However, it is very expensive, has poor solderability, and requires additional labor for application.

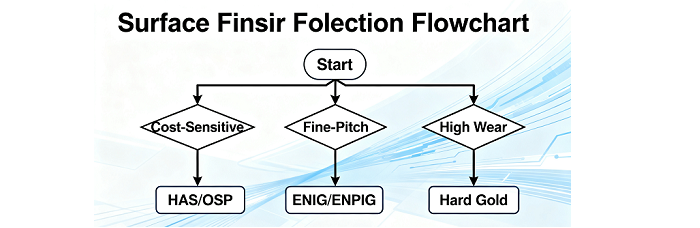

Choosing the Right Surface Finish: Key Considerations

Selecting the optimal surface finish depends on a holistic evaluation of project requirements:

Cost: HASL and OSP are ideal for budget-sensitive projects, while ENIG, ENEPIG, and Hard Gold are better for high-investment, high-reliability applications.

Component Density: Fine-pitch devices (≤0.5mm) demand ENIG, ENEPIG, or Immersion Tin for flatness, while HASL works for larger pitches.

Environmental Requirements: RoHS compliance favors ENIG, lead-free HASL, ImAg, ImSn, OSP, and ENEPIG over traditional leaded HASL.

Shelf Life: Applications with long storage times (exceeding 12 months) benefit from ENIG or Hard Gold.

Assembly Processes: Wire bonding requires ENIG or ENEPIG, while rework-friendly projects suit HASL.

Conclusion

PCB surface finishes are a critical link between design intent and real-world performance, with each option offering a unique balance of cost, reliability, and functionality. HASL remains a cost-effective choice for standard applications, while ENIG stands out for precision and high-performance needs. Specialized finishes like ENEPIG, Immersion Silver, and Hard Gold cater to niche requirements, ensuring that every PCB can be tailored to its intended use—from consumer gadgets to life-saving medical devices. By understanding the strengths, limitations, and applications of these finishes, engineers and manufacturers can make informed decisions that optimize both product quality and production efficiency.

Get Instant PCB Fabrication Quote

Helpful resources:

• Factors Influences Prices for PCB Manufacturing and Assembly

• How Much Does PCB Assembly Cost: A Complete Guide

• The Most Comprehensive Guidelines for Surface Finish Selection

• ENIG vs Immersion Silver: Surface Finish Comparison

• What Surface Finish Should I Choose When Lead-Free Requirement Weighs?