In the complex world of PCB design, material selection is just as important as design. Two basic components which have immense significance in PCB design are prepreg material and core material. Knowledge of subtle variations between the two building components can add immense value to the boards in terms of functionality, efficiency, and economic viability. In an era of miniaturized high-performance electronics, particularly in the age of 5G networks, the Internet of Things, and high-speed computing, the significance of an effective PCB stackup design cannot be compromised.

Understanding Prepreg and Core

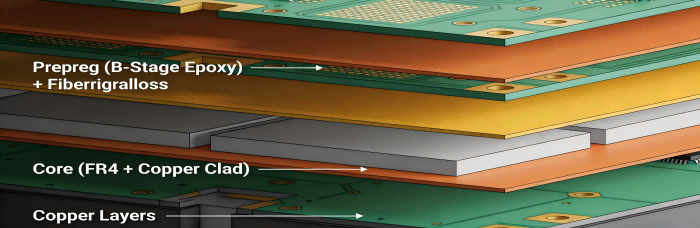

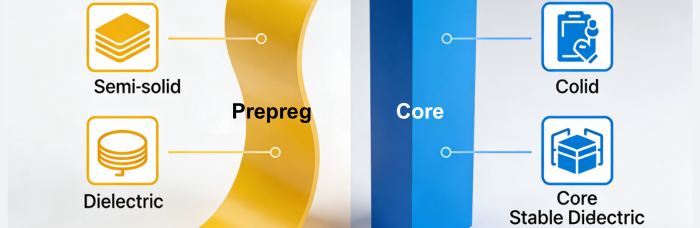

Prepreg is a type of dielectric that consists of a woven fiberglass cloth which has been pre-coated with a resin, usually epoxy. The resin has been treated in a way as to be in the B-stage. As a result of this B-stage process, the prepreg has adhesive qualities when subjected to a heat treatment during the lamination process, thus making it useful in the combination of layers of copper foil or the core materials. There are three types of thickness of prepregs: standard resin prepregs, medium resin prepregs, and high resin prepregs.

The other class of materials is the core materials that form the backbone of the PCB. Core materials are totally cured and hard laminates that consist of an FR4 composite material, which is a mix of fiberglass and epoxy with copper on both sides. The core materials are responsible for offering the strength that is needed in forming a multilayer PCB. The core materials form the base for the PCB with copper layers etched on their surfaces.

Prepreg vs Core: Main Differences

Notwithstanding the similarity between the two, the unique roles of the prepreg and core immediately categorize them into two different processes in PCB production:

State and Functionality: Core is hard and fully cured and holds copper traces. Prepreg serves both as an adhesive and an insulator and becomes fully solid after lamination of the PCB.

Copper Inclusion: Core layers are copper-clad, while prepregs are copper-free, although there is copper layer adhesion during lamination.

Dielectric Properties: The dielectric constants are consistent within cores, with benefits to controlled impedance, though prepreg may vary by a slight amount because of resin flow and glass weave orientation involved within the laminating process.

The Role of Prepreg in PCB Stackups

Prepreg acts as the adhesive and insulation in the PCB stack layers, which is very important in making multi-layer PCBs. Prepreg provides insulation between the conductive layers and also helps to build the thickness of the PCB board. There are different kinds of prepregs that can be used depending on the design required.

When it comes to real-world implementations, more than one layer of prepreg material with a thickness measured in thousands of an inch may be used by the engineer to control the thickness of the board. This arrangement can be quite crucial, especially when designing high-frequency boards. Here, the board’s impedance needs to remain consistent to ensure a reliable signal.

The Role of Core in PCB Stackups

Cores also offer the basic structure of the PCB and can be utilized to support the signal layers, power layers, and ground layers of the PCB. The rigidity and properties of the core also make them useful in the application of high-speed signals and serve as the interface where the circuit is etched in the PCB. Their properties also make them useful in areas of critical pathways of the signal.

Copper cladding in the core layer also assists in efficient power and signal transmission within the PCBs. In multi-layer configurations, cores provide good platforms upon which additional layers, placed alongside prepreg materials, are laminated upon. A core with consistent values for thickness and dielectric strength provides favorable conditions within which signals may be well managed without interference.

Practical Considerations in Material Selection

When designing a PCB stackup, there are several factors to take into account to determine the best combination of Prepreg materials and Core materials:

Application Requirements: High-speed applications can utilize cores for the critical signal layers because of their stable dielectric properties, while prepregs can help in reaching the required thicknesses along with providing insulation.

Material Cost: Though the core material of the Rogers material has superior properties, mixing these core materials along with FR4 material can prove to be cost-effective.

Precision Manufacturing: The differences in material dielectric properties make it necessary to partner with fabricators to provide a more accurate stackup design to help mitigate potential signal integrity problems such as impedance mismatch or signal loss.

Challenges and Solutions

Prepreg and core layer balancing involves factors such as prepreg thickness variation due to prepreg flow, as well as possible thermal stresses that occur in multilayer boards. Using high Tg materials and balanced stack-ups can compensate for these difficulties. This will ensure reliable board performance under environmental stresses.

The employment of high-Tg material reduces the chances of thermal expansion, as well as the likelihood of delamination, during PCB functioning. In addition, it is crucial to consider the correct type of prepreg, as well as thickness, with regard to lamination conditions to ensure consistency in lamination pressures and temperature, which is fundamental in upholding the PCB integrity.

PCBCart: Bringing Designs to Life

The complexities of PCB stackup materials require a high degree of skill to properly understand. At PCBCart, we use advanced technology with quick-turn prototyping service capabilities centered on the superior manufacturing methods required in the high-tech electronics industry. The high degree of technical expertise at our service will help in optimizing your PCB design.

PCBCart is committed to manufacturing with strict quality control and to innovation, and this means that they design and manufacture each PCB according to their requirements. The end services offered from material selection to testing and evaluation ensure that each PCB is made according to even the strictest industry standards.

The role of prepreg and core materials in PCB design is critical and cannot be overlooked. Each of these materials has unique properties that play an important part in determining the functionality of the PCB board. By knowing and utilizing the properties of the materials involved in the design of the PCBs, it is possible to produce PCBs that can work in the most demanding electrical and mechanical environments. As the trend towards the miniaturization of devices and the demand for better performance continues to increase, the mastery of the properties of materials in the design of PCBs is an important step in success. Whatever the goal of the high-frequency PCB you may be developing or planning to develop, the materials you use in the production of prepreg and core materials determine whether you’ll be mediocre or great. Choosing PCBCart, we will help achieve your dream of developing the best PCBs has become very simple.

Request for High-quality PCB Assembly & Fabrication Quote Now

Helpful Resources

• PCB Materials

• Common Defects in Multilayer PCB Manufacturing