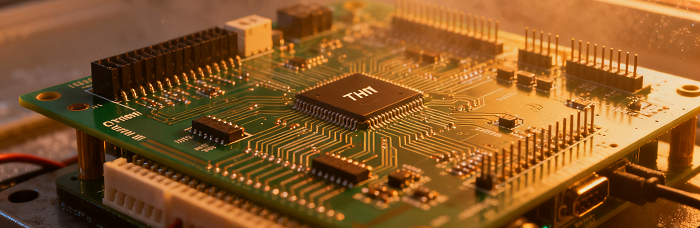

For more than five decades, THT assembly has been the cornerstone of electronics manufacturing. This "veteran" technology refuses to be defeated by the rise of miniaturization and automation. It remains irreplaceable in critical applications where durability, reliability, and power handling are non-negotiable. At PCBCart, we have been able to see how THT continues to complement the most advanced SMT technology, proving again and again that with age comes refined relevance. Let's explore why THT assembly remains a vital choice for today's electronics.

The Timeless Benefits of THT Assembly

The enduring appeal of THT can be traced to four core strengths that modern technologies struggle to match in especially high-stakes situations.

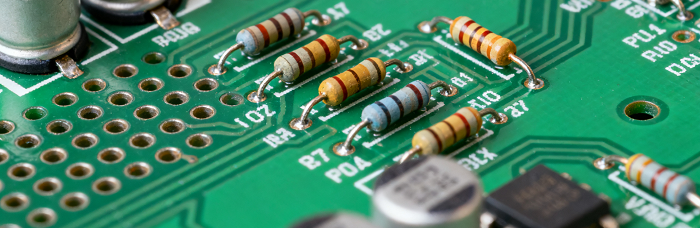

1. Unmatched Mechanical Strength

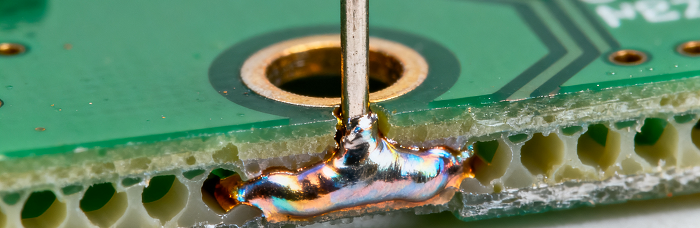

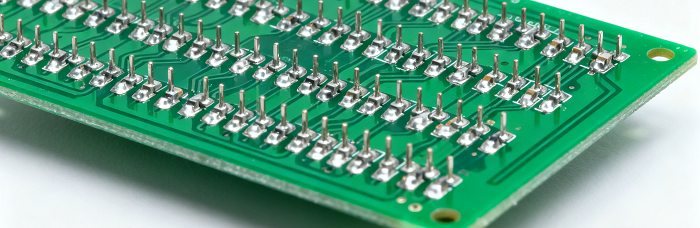

THT parts form an extremely robust mechanical bond by virtue of leads inserted through pre-drilled holes on the PCB and then soldered on the other side. This design is resistant to vibrations, shocks, and physical stress far better than surface-mounted alternatives. For devices with continuous movement, such as automotive control modules or industrial robots, THT ensures connections stay intact even over decades of use.

2. Reliability under Extreme Conditions

THT shows real resistance to extreme temperatures, high humidity, dust, and thermal cycling. Its solder joints endure without cracking through repeated heating and cooling, making it an ideal choice for aerospace, military, and outdoor electronics applications. Whether it's a satellite navigating through the vast space or a weather monitor facing storms, THT delivers the fail-safe performance that critical systems demand.

3. Ease of Prototyping and Repairs

Relatively bigger and easy-to-handle THT components are ideal for prototyping, educational projects, and low-volume production. Engineers and hobbyists can manually solder, desolder, and replace components with minimal tools, saving time and reducing frustration during the design iteration phase. In custom builds or niche products, such flexibility would mean lower costs and faster turnaround.

4. Better Power Handling

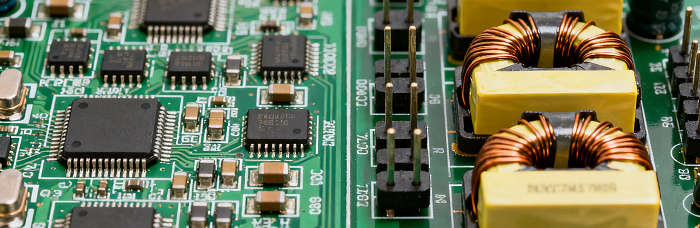

Larger THT components are good at handling high voltages, currents, and heat. Power resistors, transformers, and capacitors in THT format safely handle loads that would overheat or damage smaller SMT equivalents. In power supplies, audio amplifiers, and industrial control systems, where components often deal with voltages above 50V or currents greater than 5A, THT ensures safety and long-term performance.

Where THT Shines in Modern Electronics

While SMT dominates compact consumer gadgets, THT remains indispensable in industries where performance cannot be compromised.

Automotive Electronics

From engine control units down to the safety systems, automotive electronics have to endure constant vibration and wide temperature swings. Relays, connectors, and power components employ THT, ensuring that heavy-duty trucks and passenger cars-even electric vehicles-operate with reliability. PCBCart's THT assemblies for automotive customers meet strict industry standards for withstanding the rigors of the road for years.

Aerospace and Military Systems

In aerospace-military applications, where failure is catastrophic, the trust in THT for communication devices, radar systems, and navigation equipment has been well-founded. Its ability to resist high altitudes, extreme thermal shifts, and mechanical stress makes it a non-negotiable choice for mission-critical hardware.

Industrial Equipment

Factories, power plants, and automation systems operate in harsh environments of dust, moisture, and extreme temperatures. THT components power motor drivers, sensors, and power control systems for continuous operation that keeps industries running.

High-Power Consumer Electronics

While most consumer devices use SMT, products like power adapters, audio amplifiers, and home appliances all rely on THT for high-power components. Such parts require the stability and heat dissipation provided by THT to ensure safe and efficient performance for everyday use.

THT and SMT: A Complementary Partnership

Rarely does modern electronics use just one type of assembly method. Hybrid designs incorporate both THT and SMT on the same PCB, using the strengths of both technologies. SMT takes care of compact, low-power components such as microchips and resistors; high-power, high-stress elements like connectors and transformers come under THT.

As such, this trend is increasingly gaining ground in present renewable energy systems, LED assemblies, and medical devices-a field where space efficiency and durability must be intertwined. Here at PCBCart, we specialize in optimizing hybrid layouts to ensure seamless integration while balancing performance with cost and reliability.

Innovations Keeping THT Relevant

THT isn't stuck in the past-manufacturing developments are making it more efficient and adaptable than ever.

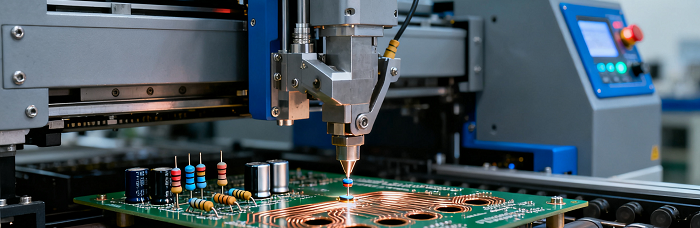

Automation Advancements

Gone are the days of purely manual THT assembly. Automated insertion machines for axial and SIP components, along with selective soldering systems, provide speed, accuracy, and labor cost reductions for production. Due to these technologies, THT is quite viable for medium-volume runs, narrowing the gap with regards to scalability for SMT.

Material and Design Improvements

The improvements in component materials further advance the thermal aspects of THT, adding to its suitability for high-power applications. Optimized PCB design minimizes space constraints, thus enabling THT components to fit into more compact devices without performance compromise.

Integration with Smart Manufacturing

THT assembly is embracing Industry 4.0: real-time process monitoring, predictive maintenance, and data-driven optimization. All this offers an increase in quality control, with a reduction in defects to ensure the assemblies meet the most specific modern requirements.

PCBCart is your partner in THT Assembly.

At PCBCart, we have been perfecting THT assembly for over 20 years, matching age-old expertise with top-notch technology. Our services include the following:

• Manual and automated THT assembly for prototypes, low-volume, and mid-volume production.

• Hybrid THT/SMT assemblies - built to your design specifications.

• Stringent quality control, including X-ray inspection and thermal cycling testing, provides assurance of reliability.

• Compliant with ISO 9001, IATF 16949, and RoHS standards, industry-specific requirements met.

Whether you build automotive electronics, aerospace systems, or custom power devices, our team of engineers collaborates directly with you to optimize your THT assembly and balance performance, cost, and lead time.

Conclusion: Legacy of THT that Continues into Modern Electronics

THT assembly may be over 50 years old, but its value in modern electronics is as strong as ever. Its unbeatable mechanical strength, reliability within the harshest of environments, ease of prototyping, and power-handling capabilities make it irreplaceable in many critical applications. When combined with SMT in hybrid designs, THT empowers innovations that neither technology could achieve in isolation.

At PCBCart, we're proud to champion THT assembly as a vital part of the electronics manufacturing ecosystem. We understand that the best products aren't built on trendy technologies-they're built on the right technologies. For your next project that demands durability, reliability, or high power handling, THT assembly isn't just an option-it's a necessity.

Ready to take advantage of the power of THT assembly for your electronics? Contact PCBCart today to discuss your project requirements and let our expertise deliver high-quality THT assemblies that your products deserve.

Helpful Resources

• Printed Circuit Boards Assembly (PCBA) Process

• How to Ensure the Quality of PCBs

• 6 Effective Ways to Cut PCB Assembly Cost Without Sacrificing Quality

• Elements Influencing SMT Soldering Quality