Within the fast-paced world of electronics, it is rather impossible to underestimate the role of printed circuit boards. The backbones of electronic devices, PCBs ensure effective connectivity and signal integrity. Amongst the several available materials for the fabrication of printed circuit boards, FR-4, Rogers, and aluminum have long since emerged as stalwarts in the industry, each having properties particularly suiting different requirements. This article analyzes in detail the mentioned materials on the basis of cost and suitability for various applications.

Understanding PCB Materials

FR-4: The Cost-Effective Cornerstone

FR-4 is generally considered to be the workhorse of PCB materials. Composed of a fibrous glass weave and epoxy resin, it combines significant mechanical strength, electrical insulation, and cost-effectiveness in an optimum way. As such, it is used throughout most electronic devices, ranging from consumer gadgets to sophisticated equipment for industrial applications.

Key Benefits: FR-4 is fairly inexpensive. The wide utilization and manufacture, which have become so standardized, have driven the cost down for this material, making it suitable for mass-produced electronic devices. It offers adequate performance in general-purpose applications, offering good thermal resistance and structural integrity.

Limitations: Despite its advantages, FR-4 falls short in applications requiring high-frequency precision or superior heat management. Its higher dielectric loss is a disadvantage in high-speed circuits where signal integrity cannot afford to weaken. Besides, its thermal conductivity is worse than such alternatives as aluminum, which makes it unsuitable for high-power applications.

Rogers: The High-Frequency Specialist

Rogers materials are synonymous with high-performance PCBs, especially in applications that involve high-frequency operation. With advanced dielectric materials like PTFE and ceramics, Rogers PCBs boast superior electrical properties, translating into minimal loss of signal and high signal integrity.

Key Benefits: The superior dielectric properties of Rogers PCBs make them indispensable for RF circuits and telecommunications where high-frequency performance is non-negotiable. Excellent thermal handling further increases their applicability for aerospace and military, where the temperature can be very extreme.

Limitations: Advanced materials and precision manufacturing embedded in Rogers PCBs result in significantly increased costs compared to FR-4. In addition, the particular nature of their development and construction makes them unnecessary in many cases in which standard performance will suffice.

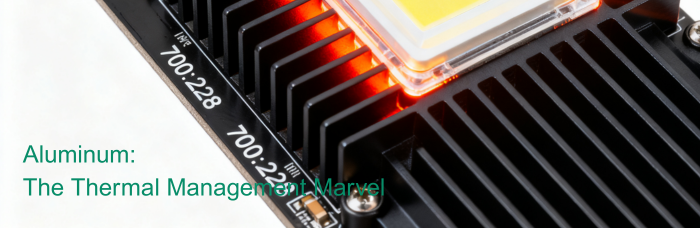

Aluminum: The Thermal Management Marvel

Aluminum PCBs feature a special metal-core construction designed to maximize heat dissipation and, therefore, are preferred in applications where effective thermal management is in demand. The combination of an aluminum substrate with a dielectric layer and copper circuit layer results in a robustly constructed PCB that is able to handle very high thermal loads.

Key Benefits: The most prominent advantage of aluminum PCBs is their heat-sink capability, which allows the effective dissipation of heat away from the core components. This can be very helpful for applications with high-power requirements, including LED lighting and power electronics, where the life of components depends on the heat dissipation.

Limitations: While offering unparalleled thermal performance, aluminum PCBs can be costlier than traditional FR-4 due to the metal-core construction. They are unsuitable for high-frequency applications; hence, their utilization is restricted to power-heavy environments.

Cost Analysis: Assessing the Economic Impact

In the case of a budget-constrained project, one would consider the cost as one of the most important factors in selecting a PCB material. Here's how the three materials compare:

FR-4: FR-4 is the most economical choice for applications where budget efficiency outweighs the need for high-end performance. FR-4 has a low manufacturing cost due to the wide availability and simplicity of processing, making it perfect for most consumer electronics in great quantities.

Rogers: This material has advanced manufacturing requirements and specialized materials, therefore it is more expensive. Such material is well justified where high frequency and low dielectric loss are major factors. The advantages of Rogers in performance outweigh the higher expenses for RF circuits and other complicated electronic systems.

Aluminum: Generally costlier than FR-4 due to its complex fabrication and metallic components, an aluminum-based PCB is still cheaper in most applications compared to Rogers. This cost becomes more or less irrelevant as the life span and reliability it offers in heat-intensive applications pay for the extra cost associated with them, striking a balance between cost and performance.

Key Performance Considerations

High-Frequency Applications: For high-frequency applications, Rogers is unparalleled, offering electrically superior properties for signal integrity. In such cases, FR-4 and aluminum are behind because they cannot offer the same low-loss, high-speed performance as the materials by Rogers.

Heat Management: Aluminum PCBs are at the front line regarding thermal management. It goes to say that, where heat dissipation becomes a priority, they become the ultimate choice. FR-4 and Rogers also exhibit thermal properties; however, the presence of metal-core construction in aluminum makes it an efficient heat sink.

General Electronics: FR-4 still is dominating in general electronics because of its reasonable cost and good enough performance for general applications. It is also the default choice for most consumer and industrial devices.

Making the Right Choice

The selection of the proper material for the PCB manufacturing process is a rather intricate decision, involving several technical project requirements and budgetary considerations. Here are some guidelines:

FR-4 grade PCBs should be used where cost is the driving factor, and the application doesn't require special frequency handling or thermal performance. FR-4 material is generally inexpensive and thus suitable for consumer electronics, simple industrial equipment, and automotive applications that don't need high performance on any of these aspects.

Rogers PCBs are applied where high-frequency precision is required, such as RF circuits, telecommunication, and advanced aerospace technologies. Although more expensive, the performance benefits in these fields make them well worth the investment.

Choose Aluminum PCBs for high-power applications where thermal management is critical to prevent component failure and ensure long-term reliability. Ideal for LED lighting, power electronics, and other heat-intensive applications, aluminum provides a reliable balance of cost and performance.

In the end, choosing the appropriate material for a PCB is one of the most important choices in electronics manufacturing; it directly affects device performance and cost. FR-4 is a cost-effective option suitable for general-purpose applications and, therefore, very appropriate for mass production when cost is a critical factor. Rogers materials, however, are ideal for high-frequency applications since their substrate materials offer minimum signal loss and thus make excellent results possible in RF and telecommunication applications, though at a higher cost. Aluminum PCBs are outstanding in thermal management; they are reliable heat dissipation solutions for high-power applications. By understanding these materials' distinct advantages and limitations, manufacturers can align their material choices with specific project requirements, leading to optimized device performance and sustainable cost management.

At PCBCart, we're committed to providing the best-in-class PCB solutions catering to the diverse requirements of the electronics industry. With our vast experience, along with advanced facilities, we provide custom PCB fabrication services that meet the highest quality standards. Be it FR-4 offering cost-effectiveness, Rogers with high-frequency clarity, or aluminum for the best thermal management, precision, and reliability are ensured in each product at PCBCart. Our commitment to customer satisfaction and innovations places us ahead as a reliable PCB fabrication partner. Request a quote from the website today and let PCBCart's exceptional services empower your next electronic venture.

Request for High-Quality PCB Assembly & Fabrication Quote

Helpful resources:

• A Comprehensive Introduction on Aluminum PCBs

• PCB Material Selection Based on Electrical Performance and Cost

• How to Select Material for Your PCBs from Cost and Reliability Considerations

• Metal Core PCB an Ideal Solution to Thermal Issues