In the global PCB industry, adherence to standardized guidelines is non-negotiable for ensuring product quality, reliability, and manufacturability. Two foundational standards from the Association Connecting Electronics Industries (IPC) stand out: IPC-6012 and IPC-A-600. While both are critical to PCB production, they serve distinct purposes that directly impact design, manufacturing, and inspection workflows. At PCBCart, we leverage these standards to deliver high-performance PCBs tailored to diverse industry needs—from consumer electronics to aerospace and medical devices. This article breaks down their core differences, applications, and how to choose the right one for your project.

What Are IPC-6012 and IPC-A-600?

Before diving into comparisons, it's essential to grasp the core mission of each standard.

IPC-6012: Performance and Qualification for Rigid PCBs

IPC-6012 is a performance-driven specification that defines the manufacturing and qualification requirements for rigid printed circuit boards. As part of the IPC-6010 series (with IPC-6011 as its generic base document), it outlines rigorous criteria for materials, fabrication processes, and product performance across three PCB classes (Class 1: general electronics, Class 2: dedicated service, Class 3: high-reliability applications like aerospace and medical).

Its scope covers critical aspects such as dielectric materials, conductor dimensions, plating thickness, solder mask specifications, structural integrity, thermal stress testing, and cleanliness. It also includes industry-specific addendums:

· IPC-6012EA (2021): For automotive PCBs, with enhanced requirements for vibration and thermal stress resistance.

· IPC-6012ES (2020): For space and military applications, addressing extreme thermal cycling and vibration.

· IPC-6012EM (2020): For medical-grade PCBs, supporting finer features (e.g., conductors <60μm, vias <100μm) than standard HDI technology.

The latest revision, IPC-6012E (March 2020, Amend 1 4/22), integrates modern advancements like back-drilled structures, improved solderability testing, and microvia performance validation.

IPC-A-600: Visual Acceptance Criteria for PCBs

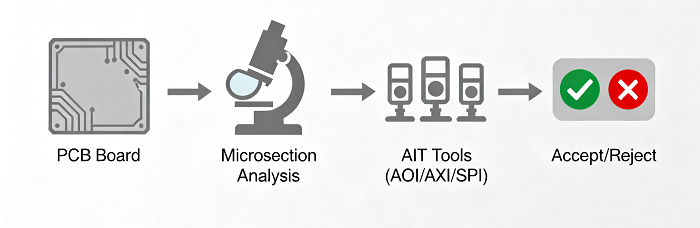

IPC-A-600 (also known as IPC-600) is the industry's go-to visual inspection standard. Unlike IPC-6012's focus on performance, it provides graphical illustrations and clear criteria for evaluating the acceptability of PCBs—both externally observable (e.g., surface defects) and internally observable (e.g., laminar integrity, via quality, requiring microsection analysis).

This standard aligns with the IPC-6010 series and J-STD-003, covering rigid, metal-core, HDI, rigid-flex, and flexible PCBs. It details ideal, acceptable, and rejectable conditions for key features:

· PCB thickness, hole dimensions, and annular ring alignment.

· Solder mask coverage, surface plating quality, and dielectric thickness.

· Defects like voids, delamination, lifted lands, and wicking.

The latest revision, IPC-A-600K (July 2020), expands on dielectric removal, back-drilled structures, and microvia contact dimensions, while syncing with IPC-6012D and IPC-6013C. It also supports automated inspection technologies (AIT) such as AXI, AOI, and SPI, streamlining defect detection in early production stages.

Core Differences: IPC-6012 vs. IPC-A-600

The two standards complement each other but serve distinct roles in the PCB lifecycle:

|

Aspect |

IPC-6012 |

IPC-A-600 |

|

Primary Focus |

Performance and manufacturing requirements |

Visual acceptance and inspection criteria |

|

Purpose |

Guides PCB fabrication to ensure reliability and compliance |

Validates finished PCBs meet quality standards |

|

Content Type |

Technical specifications (materials, processes, testing) |

Graphical illustrations + defect tolerances |

|

Application Scope |

Rigid PCBs (with industry-specific addendums) |

Rigid, flexible, rigid-flex, HDI, metal-core PCBs |

|

Key Users |

PCB designers, manufacturers, and qualification teams |

Inspectors, quality control (QC) personnel, customers |

In short: IPC-6012 answers “How should the PCB be made?” while IPC-A-600 answers “Does the finished PCB meet the required quality?”

Which Standard Should You Choose?

The decision hinges on your role in the supply chain and project requirements—though high-quality PCB production nearly always requires both.

Choose IPC-6012 If:

· You're a designer or manufacturer producing rigid PCBs. It provides the technical framework to ensure manufacturability, safety, and performance.

· Your project targets specialized industries (automotive, aerospace, medical). The addendums (EA, ES, EM) address unique environmental and reliability demands.

· You need to define class-specific requirements (e.g., Class 3 for mission-critical devices). IPC-6012's detailed specs for plating thickness, conductor spacing, and thermal stress testing ensure compliance.

At PCBCart, we use IPC-6012 as the foundation for all rigid PCB manufacturing. Our engineering team adheres to its material and process guidelines to avoid delays, reduce rejections, and deliver boards that perform consistently in real-world conditions.

Choose IPC-A-600 If:

· You're a customer or QC professional verifying finished PCB quality. Its visual references make it easy to identify defects without deep technical expertise.

· You need to align with inspection workflows. It's the global benchmark for accepting or rejecting PCBs based on visual and microsectional evaluation.

· You require compatibility with automated inspection tools. IPC-A-600K's support for AIT ensures fast, accurate quality checks at scale.

PCBCart's QC process relies on IPC-A-600 as the primary inspection standard. Every board undergoes rigorous visual and microscopic checks—from solder mask coverage to via integrity—to ensure it meets or exceeds customer expectations.

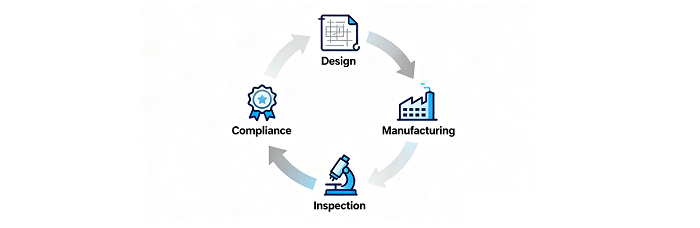

The Bottom Line: Use Both for Optimal Results

Neither standard works in isolation. For high-grade PCBs, IPC-6012 ensures the board is manufactured correctly, while IPC-A-600 confirms it meets quality standards. Misinterpreting either can lead to costly reworks or field failures—for example, failing to specify copper weight states (start vs. finished) in fab drawings (per IPC-6012) or missing hidden voids (detectable via IPC-A-600's microsection guidelines).

How PCBCart Leverages These Standards for Your Success

At PCBCart, we integrate IPC-6012 and IPC-A-600 into every step of our process:

1. Design Support: Our engineers reference IPC-6012 to optimize layouts for manufacturability, ensuring compliance with class-specific requirements.

2. Manufacturing Excellence: We follow IPC-6012's material and process specs, from dielectric selection to thermal stress testing, for consistent quality.

3. Rigorous Inspection: Our QC team uses IPC-A-600K to perform 100% visual and automated inspections, verifying every feature against acceptable criteria.

4. Industry-Specific Compliance: We apply addendums like IPC-6012EA (automotive) and IPC-6012ES (aerospace) to meet specialized demands.

Whether you're building consumer electronics, medical devices, or aerospace systems, our adherence to these IPC standards ensures your PCBs are reliable, compliant, and ready for integration.

Conclusion

IPC-6012 and IPC-A-600 are irreplaceable tools for the PCB industry—one guiding manufacturing, the other validating quality. By understanding their differences and using them in tandem, you can avoid costly errors and deliver products that stand out in a competitive market. At PCBCart, we're committed to upholding these standards to provide you with PCBs that meet your exact requirements, every time.

If you're unsure which class or revision applies to your project, our team of IPC-certified experts is here to help. Contact us today to discuss your PCB needs and experience the PCBCart difference—quality you can see, performance you can trust.

Helpful resources:

• Acceptance Criteria of IPC-A-600 in PCB Manufacturing

• Essential Standards for Medical PCB Assembly

• PCBCart Certifications

• PCB Manufacturing Process — A Step-by-Step Guide

• How to Ensure the Quality of PCBs