A well-executed silkscreen layer is the unsung hero of PCB design, bridging the gap between design intent and manufacturing reality. As a critical visual guide for assembly, troubleshooting, and component identification, it directly impacts production efficiency and long-term board reliability. PCBCart, a leader in PCB manufacturing and design solutions, brings you this expert guide to mastering silkscreen best practices—focusing on font size, placement, and color—to elevate your PCB designs.

Font Size: Balancing Legibility and Space Efficiency

Font size and stroke width are the foundation of readable silkscreen markings, with industry standards and manufacturing capabilities dictating key parameters.

Core Size Guidelines

• Minimum Requirements: Adhere to a minimum font height of 0.040 inches (40 mils / 1.016 mm) and a stroke width of 0.006 inches (6 mils / 0.152 mm) for consistent readability. For advanced printing methods like Direct Legend Printing (DLP), sizes can go as low as 0.02 inches (20 mils), but this is not recommended for critical markings.

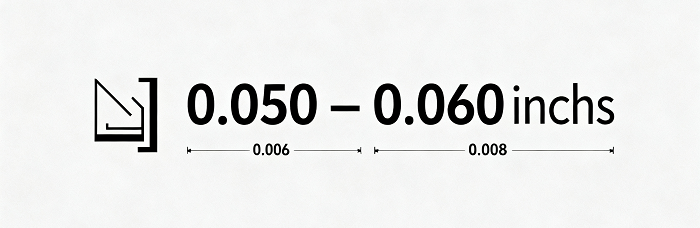

• Ideal Range: Opt for a font height of 0.050–0.060 inches (1.27–1.524 mm) and a stroke width of 0.006–0.008 inches (0.152–0.203 mm) for optimal visibility across assembly and maintenance scenarios.

• Maximum Limit: Avoid exceeding 0.080 inches (2.032 mm) unless space allows, as oversized text can clutter high-density boards.

Font Style & Additional Considerations

• Use simple sans-serif fonts (e.g., Arial, Helvetica) to ensure clarity at small sizes—serif or decorative fonts often distort during printing.

• Maintain an aspect ratio (width to height) of 1:6 for text to prevent blurring or line merging.

• Confirm your manufacturer's capabilities: Most PCB fabricators support stroke widths between 0.004–0.008 inches (0.102–0.203 mm), so align your design with their resolution limits.

Placement: Clarity, Accessibility, and Manufacturing Compatibility

Silkscreen placement must prioritize usability while avoiding conflicts with board components and manufacturing processes.

Key Placement Rules

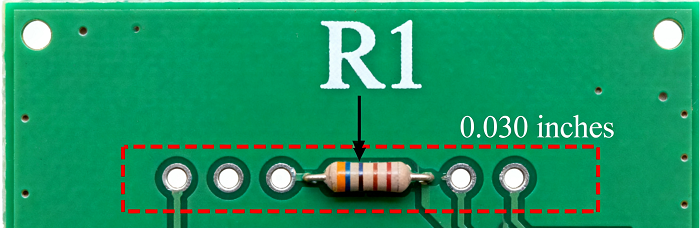

• Proximity to Components: Position reference designators (e.g., R1, C2) and polarity markers within 0.030 inches (0.762 mm) of their associated components for unambiguous identification.

• Clearance Requirements: Maintain a minimum 6-mil (0.152 mm) gap between silkscreen elements and conductive features (solder pads, vias, test points) to prevent insulation issues and ensure solder joint integrity.

• Uniform Orientation: Align all text to be readable from a single angle (left-to-right, top-to-bottom) to eliminate the need for rotating the board during assembly.

• Avoid Overlaps: Never place silkscreen over component bodies, solder mask openings, or vias—overlaps render markings unreadable post-assembly. Use PCB design software's clearance rules to automate this check.

Prioritize Critical Information

In space-constrained designs, prioritize essential markings:

1. Reference designators and polarity indicators (for diodes, LEDs, capacitors)

2. Pin-1 markers for ICs and connectors

3. Test points and version/revision numbers

4. Regulatory and manufacturer identifiers (per IPC standards)

Non-essential elements like logos or lengthy text can be omitted to reduce clutter.

Color: Contrast, Functionality, and Manufacturability

Silkscreen color choice hinges on contrast, solder mask compatibility, and practicality—with standard options balancing visibility and cost-effectiveness.

Recommended Color Options

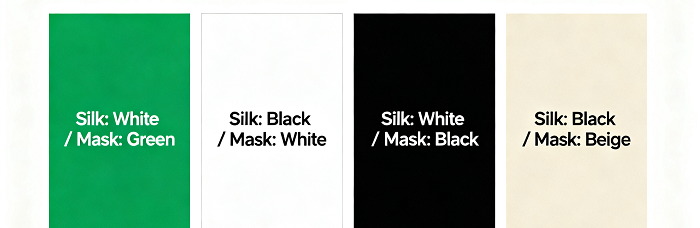

• White: The industry standard, offering exceptional contrast on dark solder masks (green, blue, black) and ensuring broad manufacturability.

• Black: Ideal for light-colored solder masks (white, beige) to avoid glare and maintain readability.

• Accent Colors: Yellow or red can be used for critical warnings or specific design needs, but confirm availability with your manufacturer.

Colors to Avoid

Steer clear of non-standard colors like pink, as they often pose legibility challenges, increase production costs, and may not be supported by all fabricators.Contrast Best Practices

• Pair light silkscreen ink with dark solder masks and vice versa to maximize readability in varying lighting conditions (factory floors, repair benches).

• Test color combinations on prototypes: Even "standard" pairings can vary in visibility based on ink quality and board material.

PCBCart's Expert Tips for Silkscreen Excellence

1. Prototype First: Order a prototype to inspect silkscreen legibility under real-world conditions—adjust font size or placement if text is hard to read without magnification.

2. Align with IPC Standards: Follow IPC guidelines for silkscreen dimensions and clearance to ensure compatibility with global manufacturing processes.

3. Choose the Right Printing Method:

• Liquid Photo Imaging (LPI): For high-precision, space-efficient designs (supports 4-mil line widths).

• Direct Legend Printing (DLP): Ideal for complex, small-scale markings (fast setup, high accuracy).

• Traditional Screen Printing: Cost-effective for simple designs but requires larger text sizes.

4. Mirror Bottom-Layer Silkscreen: Ensure bottom-side markings are mirrored in Gerber files for correct alignment during manufacturing.

Conclusion

Mastering PCB silkscreen design—from font size and placement to color selection—reduces assembly errors, streamlines maintenance, and ensures seamless collaboration between design and manufacturing teams. By following these best practices, you create PCBs that are not only functional but also user-friendly for technicians and assemblers alike.

PCBCart's team of DFM experts is dedicated to helping you optimize every aspect of your PCB design, including silkscreen. Whether you need guidance on size adjustments, color selection, or printing method compatibility, we’re here to ensure your silkscreen meets the highest standards of clarity and manufacturability.

Helpful resources:

• Solder Mask and Silkscreen Design Tips You Can't Miss

• Common PCB Design Issues: Silkscreen Edition

• How to Generate Perfect Gerber Files (Including Silkscreen Layer)

• Design Requirement of SMT PCBs Part Four: Mark & Silkscreen

• PCB Layout Best Practices: Silkscreen, Fiducials, and Tooling Holes