In the demanding world of electronics assembly, soldering is not only a basic skill—but a cornerstone of the entire assembly process. At PCBCart, we understand that the correct selection of solder can be paramount, especially when choosing between solder wire and solder paste. It can make an enormous difference in both the performance and reliability of your projects. Regardless of whether you are using surface-mount technology (SMT) or through-hole technology (THT), this comprehensive guide is designed to demystify the variations, benefits, and optimal uses of each soldering material.

Introduction to Soldering Materials

Soldering constitutes the foundation of electrical joining in circuits, and two major materials reign supreme in the process: solder paste and solder wire. Both share the ultimate goal of joining metal surfaces but have profoundly different forms, uses, and appropriateness for different tasks. Strong understanding of their distinctions is central to success in gaining consistent results, whether your concern is a precision hobby project or large-scale production operation.

Solder Paste: Developed for Accuracy and Automation

What Is Solder Paste?

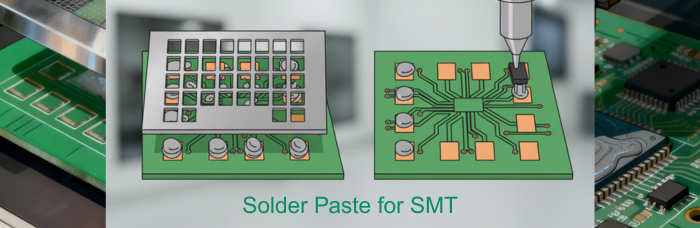

Solder paste is a mixture of minute solder alloy particles in a flux medium, used primarily in SMT applications where accuracy cannot be compromised. The function of the flux is also significant since it cleans the metal surfaces to ensure good bonds when the paste melts in the reflow process.

Advantages of Solder Paste:

Precision: Applicable to small components, such as 0402 or 0201 resistors, solder paste can be applied with high precision through the use of stencils, minimizing waste and promoting uniformity.

Automation-Compatible: The preferred option for automated assembly lines, solder paste makes mass production possible through machine placement and reflow ovens.

Efficiency in Assembly: Its pre-application conserves manual labor, thereby time, and optimizes efficiency in high-volume operations.

Built-in Flux: Integral flux eliminates the need for additional flux application, simplifying the soldering process.

When to Use Solder Paste:

Surface-Mount Technology (SMT): Solder paste is the best choice for creating clean, reliable joints in SMT, particularly for components like chip resistors, capacitors, or integrated circuits.

High-Volume Production: It works optimally in a setup where low defect rates and large batches are the requirement, offering the accuracy required for volume production.

Fine-Pitch Components: For fine lead spacing components such as 0.5mm pitch QFP packages, solder paste precisely deposited via a stencil prevents bridging and provides even distribution.

Solder Wire: Champion of Versatility and Control

What Is Solder Wire?

Solder wire consists of a flexible strand, which typically contains a flux core, designed mainly for hand soldering using soldering irons. Its degree of control and user-friendliness place it singularly well for THT, repairs, and prototyping.

Benefits of Solder Wire:

Direct Control: Provides physical control over soldering applications, optimally suited for manual applications.

Versatility in Application: Tolerates a broad range of applications, from soldering large through-hole joints to making delicate SMT repairs.

Cost-Effectiveness: Less costly for small-volume applications; obviates the need for investment in specialized equipment.

Ease of Use: Solder wire is typically easy for newcomers because it is utilized in a straightforward manner with a standard soldering iron.

When to Use Solder Wire:

Through-Hole Technology (THT): Best for components with leads inserted into a PCB, solder wire provides extremely robust mechanical joints.

Repairs and Reworks: To repair connections or substitute a component, providing accurate control over the amount used.

Prototyping and Hobby Projects: More hands-on and economical for smaller projects when complex setups are not required.

Soldering Techniques: Paste vs. Wire in Action

Soldering techniques suit each material category:

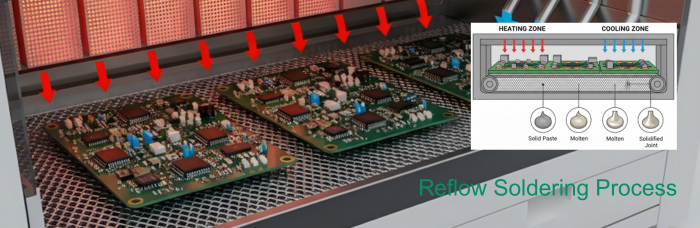

Reflow Soldering (Solder Paste): The signature method of SMT assembly involves solder paste placement on PCB pads, the addition of components, followed by the use of a reflow oven to heat the joints.

Hand Soldering (Solder Wire): Uses a soldering iron to heat wire on to joints, offering THT, repair, and small project control but needs expertise so that defects like cold joints or overheat are prevented.

Hot Air Rework (Both Paste and Wire): Solder wire and paste can both be used for hot air rework procedures, depending on the procedure—solder paste for reflowing small areas and wire for desoldering components.

Making the Right Choice for Your Needs

The choice between solder wire and solder paste depends greatly on the components and project size:

Component Size: Solder paste is best for components smaller than 1mm in size. Conversely, larger components or through-hole designs are well-suited for solder wire.

Volume of Work: High-volume SMT work or over 10 boards takes advantage of the solder paste investment and equipment needed. Solder wire is best for one-off work.

Skill Level: Beginners may find solder wire easier to use, while solder paste requires expertise in stencils and reflow tools.

Budget Considerations: Solder wire is the cheaper option for small work, while solder paste setups have a higher initial equipment cost.

Lastly, the use of solder wire or solder paste depends on the specific needs of your project. Solder paste provides unbeatable precision and productivity in SMT and large volume production and thus is irreplaceable in the assembly of modern electronics. Solder wire stands out with its versatility, ease of use, and irreplaceability in hand soldering, THT, and quick repairs.

At PCBCart, we are committed to backing up your electronics projects with quality materials and expertise. Whether it is guiding you through soldering techniques or offering the finest quality PCB manufacturing, we are here to help your success shine through, making your connections as reliable as they are strong.

Request for Cost-Effective & Advanced PCB Assembly

Helpful resources:

• Wave Soldering vs. Reflow Soldering

• What is Solder Flux in PCB Manufacturing?

• How to Prevent Poor Solder Wetting?

• Comparison between Through-Hole Assembly (THA) and Surface Mount Assembly (SMA)