Selecting a suitable Partner for your PCBA is a critical step which can prove to be a make-or-break factor in your product’s success in the market. With an increasing complexity in the Electronics Industry, it is important to move beyond Cost & Lead Time in choosing your PCBA Partner. Through this in-depth article, you will gain insight into important aspects which will make your selection process an enlightened one, in accordance with your short-term & long-term plans.

Comprehensive Capabilities

While assessing a PCBA service provider, it is important to first analyze them based on the scope of their service delivery. A good PCBA service provider should be able to deliver end-to-end solutions when it comes to designing and PCBA assembly, which involves both surface-mount technology and through-hole technology. While this can be considered a matter of flexibility, being able to address different product requirements is a critical hallmark of a provider capable of satisfying your requirements. Use of SMT is vital in developing small and dense devices, which can benefit from its cost-effectiveness and efficiency. THT is important in devices where higher mechanical strength is a requirement, such as in power devices and reliable environments.

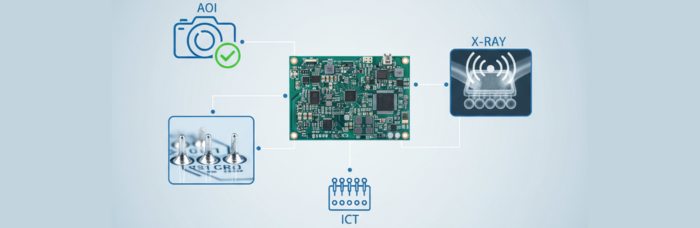

Furthermore, make sure your provider is capable of testing their assemblies comprehensively. Request access to technology such as Automated Optical Inspection, X-ray inspection, and In-Circuit Test solutions. As can be noted, these testing solutions are very important in ensuring that all PCBs delivered are error-free. Automated Optical Inspection can quickly scan and identify errors in soldering and assemblies, with X-ray inspection assessing solder joints in densely packed PCBS. On the other hand, In-Circuit Test assessment is important in ensuring that all PCBS function according to designs. In addition, functions and environmental tests can be performed to affirm if all functions will work well in the operating environment.

Industry Experience and Compliance

The role of sector expertise should not be undervalued. PCBAs have different requirements in various sectors such as medical, automotive, and consumer electronics. Every industry will have a different set of requirements and solutions. Hence, identifying a reliable PCBA service provider with sector-specific expertise can make all the difference. Make sure they have experience in your sector and an understanding of the requirements your industry imposes. Sector-specific certifications, such as ISO 9001 which targets quality management systems in industries, ISO 13485 for medical devices, and AS9100D for Aerospace, indicate a service provider's focus on high-quality output.

Supply Chain and Cost Efficiency

A good supply chain strategy is an imperative in a successful PCBA collaboration. Here, an assessment of how a potential collaborator treats their suppliers, procurement of components, and subsequent strategies in case of a shortage or obsolescence of components is considered essential. The factor of economies of scale in the procurement of components can lead to cost savings, which are usually reflected in the reduced charges to clients. Cost transparency is another important factor in a PCBA collaboration. Engaging in a serious cost structure talk with a collaborator is important in order not to incur any extra charges in a project. A collaborator who breaks down all cost components, including operations, into a detailed analysis shows transparency in financial matters.

Scalability and Flexibility

The capability of your PCBA partnering company to fulfill your production volume requirements and scale up when your business grows is a major consideration. This will include assessing their processing time for both prototype and mass production, in addition to their capability in fast-track processing. Having a partnering company with an ability to scale up production without any negative impacts on quality and time will be very important in helping your business grow in response to market requirements. Other considerations will include companies that can provide complete turnkey solutions. Such companies can handle all aspects of your PCB requirement from design to processing, providing you with packaged and ready-to-ship PCBs.

Communication & Support

Irrespective of your selection among local or international partners, a strong communication protocol is non-negotiable. A local partner can prove beneficial in case of good communication and perhaps a visit. Additionally, an international partner can prove economical. Moreover, a good communication system, which can be guaranteed with project managers or account managers, is essential when working with a team. Timely, efficient, and well-informed responses can do wonders to your team and greatly help in your project success. Assessing your customer service support by your partners in reviews can prove helpful in judging them.

Final Considerations

With this in mind, it is important to check if potential PCBA partners have in-house capabilities for all fabrication and assembly steps because this will in most cases lead to good quality control and efficiency. Having a partner with up-to-date technology shows they prioritize innovation and quality. Such investments go beyond just improving production capabilities because they will be able to keep up with evolving complexities via updated methodologies. Lastly, evaluate their engineering capabilities. Having in-house engineers is critical to fixing designs fast, especially in phases such as testing/prototyping.

Through diligent attention to these important considerations, you can successfully short-list your PCBA business partner not only to address your current requirements but also to help you in your future strategy. The most important factor in making your product development projects a successful reality is creating a collective and transparent relationship with your PCBA manufacturer, which will not only improve your working process, but it will also establish a strong foothold in your future technological successes.

As PCBCart, we are proud to bring you a level of industry expertise, technology, and service capabilities unlike anyone else in the industry, all to address diverse production requirements in electronics. With our commitment to quality and innovation, our advanced service centers and engineering teams work to deliver each project with meticulous detail and attention. Our effective supply chain and pricing transparency speak volumes for our commitment to trust, effectiveness, and integrity in our collaborations. Let our capabilities and offerings speak for you to become part of our success stories. Whether you have a new project in mind or need a boost in your production scale, submit a quote with us today to experience our expertise in PCBA globally.

Request for High-quality PCB Assembly & Fabrication Quote Now

Helpful Resources

• How to Evaluate A PCB Manufacturer or A PCB Assembler

• 6 Effective Ways to Cut PCB Assembly Cost Without Sacrificing Quality

• How to Ensure the Quality of PCBs

• Some Handy Methods in Evaluating SMT Assembler's Capabilities

• PCB Assembly Inspection Methods