In the rapidly developing field of electronics manufacturing, the turnkey PCB service has become the measure of perfection when it comes to efficiency and ease of processing, as it deals with component procurement all the way to final delivery. Well-organized documentation is not only time-saving, as has already been mentioned, but is also a guarantee of quality in the final output. This detailed tutorial on a successful turnkey PCB service is based on well-established expertise.

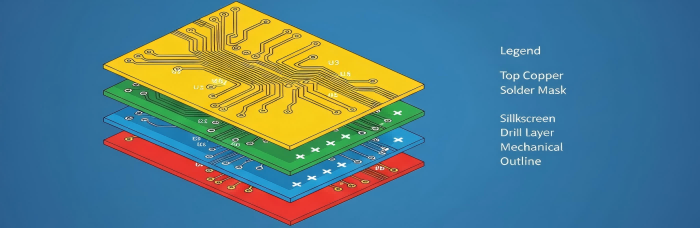

Gerber/ODB++ Files

Gerber files or their substitutes, ODB++ files, are the technological basis for PCB production. Such files contain a blueprint of the layers and components of the PCB that helps in transforming the PCB design into a physical board.

Critical Elements of Gerber Files/ODB++ Files

Copper Layer Files

Describe electrical pathways and connections, which play a vital role.

Silkscreen

Represent text and symbols, establishing necessary points along the board.

Solder Mask Files

Indicate protected regions on the PCB to avoid unwanted solder landing.

Drill Files

Describe the size and positioning of all drilling holes, including vias, with accurate alignment and operation.

Mechanical Files

Outline the board dimensions, cut outs, and routing which are required to fit the board into the housing.

When to choose the Gerber file format or use the ODB++ file format depends on the requirements you have and the preferences of the manufacturer. Both formats offer a complete design plan that is essential when you want to have the design fabricated.

Bill of Materials (BOM)

The Bill of Materials stands as an important document that presents all components needed for assembly on the PCB board.

Critical Components Of BOM

Part Numbers: These are manufacturer or supplier-specific part numbers to make sure the right components are procured.

Component Descriptions & Quantities: Detailed descriptions & exact quantities for each component to eliminate miscommunication.

Reference Designators: Use reference designators to align components on bills of material (BOMs) to their associated components on design files.

Package Types: Information about the physical form of each package component, necessary for assembly and soldering.

A detailed Bill of Materials helps in the avoidance of costly manufacturing errors and plays an important role in the elimination of delays in the procurement of components as well as the placement of components.

Centroid (Pick and Place) Files

The Centroid file, or Pick and Place file, is an essential tool in efficient PCB assembly. It delivers exact coordinate positions in x and y values as well as orientations in aiding assembly machines.

Coordinates and Rotation: Exact coordinates and rotations are specified to position each element exactly as required.

Layer Information: It gives information about which component belongs to which layer and is necessary when building multiple-layer designs.

This file helps avoid placement errors and greatly improves the speed at which the assembly process is conducted.

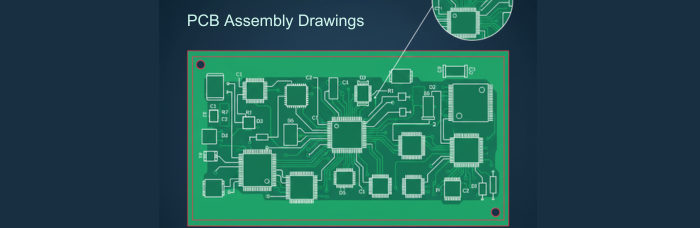

Assembly Drawings

PCB Assembly drawings are a macro view of where and how components are to be positioned, usually supplied in PDF format. They can be essential when designators cannot be physically marked on the PCB.

The Role of Assembly Drawings

Visual Reference: Provide a complete perspective on component placement so that all involved individuals have an understanding of what is being referred to.

Supplement to Digital Files: This is used to add clarity to digital files, specifically for complex designs.

This helps ensure that all the marks of reference are clearly visible, making the process of automated and/or manual checks easier.

Special Requirements Documentation

Sometimes, a PCB design might have some special features or requirements, such as impedance, gold fingers, or a special board thickness. Adding such requirements to your documentation will make sure that these requirements are also met during production.

Highlighting Special Requirements

Impedance Control and Gold Fingers: Special handling procedures may play an essential part for designs demanding particular specifications or improved robustness.

Blind/Buried Vias: These involve special consideration in the manufacturing routing files/drill files because of the vias' depth

Unique Stack-Ups or Material Specs: Provide narrative descriptions if the project design varies from the standard stack-up configurations.

Precise requirements documentation, usually done through text or PDF files, helps to incorporate the requirements during production to avoid costly mistakes.

Preliminary Files

In contexts where design completion is not accomplished, soft files such as early Gerber files can be used for estimating initial quotes.

The Role of Preliminary Files

Early Estimation: It enables cost estimation even when the design is still in progress.

Iterative Design Feedback: Enables feedback to go back and forth between the designer and manufacturer in order to hone in on final specifications.

This will help to greatly optimize the procedure of moving from design to production, and the end product will not experience any kind of delays.

Comprehensive Documentation and Communication

Clearly communicating and properly documenting are essential in any assembly procedure of a PCB. Supplying as much information as possible about testing procedures and schematic files can better enable a partnership between you and manufacturers for assembly of your board.

Good Documentation Practice

Troubleshooting and Verification: Complete records enable quick problem detection and remediation during product manufacturing.

Alignment in Project Vision: Aligns all stakeholders to achieve the common goals of production to eliminate the possibility of miscommunication and errors.

Well-documented work in this area not only helps in smooth transitioning from design, manufacture, and assembly but also helps in ascertaining whether the final output meets the required specifications.

Turnkey PCB production requires accurate and detailed documentation to be provided. This helps to provide the entire document required for the process to take place smoothly and also helps to save time and cost. In partnership with PCBCart, you will have the advantage of our experience and dedication to delivering nothing short of the best quality for the successful production of your design. Contact us for further help or to learn more.

Get an Instant Quote for Advanced PCB Assembly

Helpful Resources

• How to Generate NC Drill Files based on Different PCB Design Software

• PCB Material Selection Based on Electrical Performance and Cost

• Common PCB Footprint Errors and Prevention

• Free DFM Check

• PCB Assembly Inspection Methods