In the endless pursuit of innovation, electronics has further pushed the frontiers of what can be done in circuit board design. At the vanguard of this technology advancement are Flexible Printed Circuit Boards (Flex PCBs), which offer new frontiers far beyond the limitations of traditional rigid PCBs. As central components of modern electronics, flex PCBs are at the forefront of compact and high-performance design driven by the miniaturization of electronic components.

What are Flex Circuit Boards?

Flex circuit boards, or more familiarly referred to as flex circuits, are a specific category of printed circuit boards that are flexible, dynamic, and conformable. Unlike rigid PCBs, flex circuits are built on flexible substrates like polyimide (PI), allowing them to twist, fold, and bend. This ability makes them especially useful in spaces where space is limited and dynamic flexing is necessary.

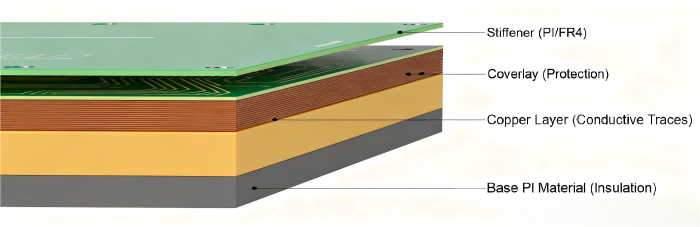

Manufacturing and Composition

Flex PCB production involves several layers with each layer having its own function:

Base PI Material: Polyimide is utilized as the base insulation because it is stable at high temperatures, flexible, and has a long lifespan. It is a tough core that can endure high temperatures and provides excellent electrical insulation. Shrink property of PI in manufacture makes it more useful, as it combines with the insulation properties needed in advanced PCB designs.

Copper Layers: Similar to the rigid PCBs, these layers are etched into conductive traces. The thickness ranges from 12 to 30 micrometers. The copper thinness keeps the board light but electrically efficient.

Coverlay: This layer of protection is deposited in order to isolate the copper circuits from environmental stress and mechanical abrasion. Coverlays also help the board's structural integrity, even where applications require high stress.

Stiffeners: Often composed of PI, FR4, or stainless steel, stiffeners provide mechanical operation support and when mating with connectors. Used in applications where aggressive mechanical stability is required.

Surface Finish: Immersion Gold, OSP, and Immersion Tin are a few of the common finishes applied to provide consistent performance and reliability. The end copper thickness may vary, typically ranging from 0.5 to 2 ounces, to accommodate different application needs.

Types of Flex Circuit Boards

Flex circuit boards can be significantly varied based on layer structure:

Single-Layer Flex PCBs: They have a trace of a single layer and are used most commonly in less sophisticated applications where there is great demand for flexibility. Thickness of these boards can be as little as 0.08 mm and hence suitable for small-sized devices.

Double-Layer Flex PCBs: As they contain conductive patterns on both sides, they offer better connectivity and functionality. Their thickness tends to be between 0.1 mm and 0.26 mm.

Multilayer Flex PCBs: They are made up of many layers, and they are used in high-end electronics. Their design makes them costlier but allows for advanced design, with more layers up to a thickness of 0.38 mm.

Rigid-Flex PCBs: These combine elements of rigid and flex circuits to offer hybrid solutions where a portion of the board must be kept flat but another section flexes. This hybrid structure accommodates flexible designs that are critical in applications with high mechanical requirements.

Benefits of Flex Circuit Boards

Flex PCBs offer significant benefits in most applications:

Light and Thin: Made of mostly polyimide, flex PCBs are extremely light in weight compared to rigid PCBs, making them ideal for portable and mobile devices. A typical two-layer flex would be 4.4 to 10 mils thick.

Flexibility: They are bendable and foldable to fill spaces that are inaccessible to rigid boards, expanding product design possibilities for medical devices and consumer electronics. Flexibility is crucial for intricate device structures, where space is an issue.

Resistance to Harsh High-Temperature Environments: Polyimide materials are resistant to extreme temperatures and can work under intense operating conditions with reliability. Flex PCBs thus find suitability for rough industrial and automotive environments.

Reliability: Fewer interconnections between components, flex PCBs minimize potential points of failure, thus making electronic products in general more reliable. Less need for connectors and cables simplifies assembly processes and minimizes connectivity issues.

Applications Across Industries

The unique characteristics of flex PCBs enable them to be utilized within a vast range of industries:

Aerospace and Automotive: Flex PCBs are utilized in LED lighting systems, sensors, and control modules that fit the contours of cars and planes. Their slender and lightweight design helps to reduce system weight.

Medical Devices: In surgical instruments or hearing aids, flex circuits enable compact and reliable device structure. They play a crucial role in delivering digital information for therapeutic and diagnostic purposes.

Consumer Electronics: Flex PCBs provide design and space flexibility in consumer electronics like smartphones and cameras. Their use in high-performance and small consumer products enables optimal performance.

Industrial and Robotics Applications: These PCBs serve the purposes of robots, drones, and self-driving cars by managing critical electrical elements. They provide control systems with accuracy in automation and robotics.

High-Definition Displays: Display drivers and screens in applications such as wearable technology and smart car HUDs are interconnected by flex circuits, facilitating ultra-thin, high-performance display solutions.

Flex PCBs have redefined the boundaries of electronic design, enabling a new generation of devices that demand compactness, flexibility, and high performance. Flex PCBs can be bent, folded, and conform to intricate spaces, and therefore are eminently suitable for application in aerospace, automotive, medical, and consumer electronics applications, to name a few. As technology speeds up and goes further with each day, the role of flex PCBs cannot be exaggerated. They are the best combination of lightweight building, resilience, and flexibility with which engineers are able to engineer smart solutions to meet the increasingly high demands of industry today.

PCBCart is leading this revolution with the integration of cutting-edge technology with unmatched know-how to deliver the finest flex PCB solutions. With a focus on quality and innovation, PCBCart offers a broad spectrum of professional services that are tailored to meet the specific needs of every client, so that your projects not only meet their specifications but exceed them in performance and reliability. Regardless of whether you're ready to quote or need to explore further the prospects of flex PCBs, PCBCart is your trusted path towards becoming a master of innovative electronic solutions.

Get an Instant Quote for Flex PCB Fabrication & Assembly

Helpful resources:

• Flexible PCB Application Development

• Primary Material of Flexible PCB

• Flex-Rigid Multi-Layer PCB Fabrication Process

• Flexible and Flex-Rigid Printed Circuit Board Applications

• Design for Manufacture and Assembly of PCBs and General Rules it Conforms to