In the ever-changing world of electronics manufacturing, there is a high level of importance for ensuring impeccable quality in printed circuit board assemblies. Surface Mount Technology lines form the backbone for the production of PCBs with complex boards being required to be manufactured in record time and with maximum efficiency. Given that even minor defects may lead to very costly failures, there is an increasing presence of inspection methods such as Automated Optical Inspection and Automated X-ray Inspection. Each method has advantages and has been suited to different needs for defect detection in PCB assemblies. This article looks into the functionalities, benefits, and limitations of AOI and AXI as a means to determining which best fits your SMT line.

Understanding AOI and AXI in SMT Inspection

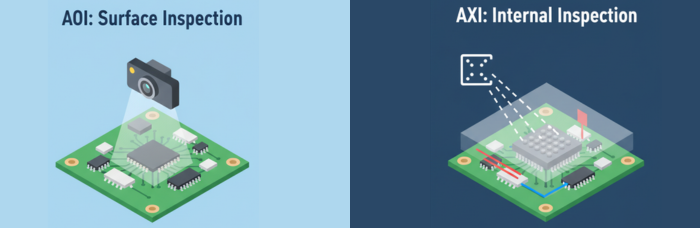

AOI and AXI are two major no-contact test methods in ensuring quality within the production of PCBs. AOI employs high-resolution cameras in conjunction with advanced lighting systems for their required visual inspections on the surfaces of PCBs, finding issues such as missing or misplaced components and solder defects. AOI can be conducted either after solder paste application or post-reflow, although the latter would assure maximal defect detection.

AXI, on the other hand, uses X-ray technology in the inspection of internal structures of PCBs and is thus irreplaceable in the checking of inner connections in parts such as Ball Grid Arrays and Chip Scale Packages. AXI's forte is the review of the internal quality and structural integrity, thus very often complementing AOI within an integrated inspection strategy.

Key Differences Between AOI and AXI

When choosing the best inspection method for your SMT line, it's important to understand the core differences between AOI and AXI. The following are the differences between AOI and AXI based on technology, defect detection capability, speed, and cost.

Technology and Inspection Approach

AOI runs on the principle of visible light and camera systems that provide detailed images of the surfaces of PCBs. It uses 2D and often 3D imagery for detailed analysis, with enhancements through machine learning algorithms that strengthen defect detection rates to as high as 95% for surface issues.

AXI, on the other hand, relies on X-ray technology to visualize inside boards and show hidden solder joints and voids. It can reach as high as 99% accuracy for catching problems in connections hidden from view, but it requires very specialized equipment and adherence to safety protocols due to radiation.

Defect Detection Capabilities

AOI is particularly good at finding surface level defects, including:

Missing or misaligned components

Solder bridges and insufficiencies

Incorrect component polarity or orientation

Tombstoning or billboard effects

However, AOI cannot inspect under components and within multilayer boards; therefore, it lacks effectiveness in the inspection of hidden joints, as in BGAs.

AXI bridges this gap in detecting internal or concealed defects, which include:

Solder voids in BGA and CSPs, where excessive voids can lead to loss of reliability

Cracks or breaks within multi-layer PCB structures

Insufficient solder inside hidden joints

While powerful for subsurface inspection, AXI does not target the area of surface defects as prime in its design, unlike AOI.

Speed and Throughput

Speed is vital in high-volume SMT productions. AOI systems are faster, taking 10-20 seconds to inspect a PCB, hence used for inline inspections that require immediate feedback. AXI is slower because the X-ray imaging is complex, taking 30-60 seconds per PCB, hence used mostly in offline or batch sampling inspections unless comprehensive internal checks are needed.

Cost and Implementation

Cost is another very important factor for the selection between AOI and AXI. Generally speaking, AOI systems are much cheaper. Their prices start at about $50,000 for an entry-level machine and reach $150,000 for an advanced model. The operational costs are also lower as no special safety precautions are needed.

AXI systems are far more expensive, ranging from $100,000 to $500,000, considering the needs of radiation shielding and safety regulation compliances. Besides, maintenance costs tend to be higher since X-ray technology involves highly specialized expertise.

Choosing the Right Solution for Your SMT Line

The choice between AOI and AXI should be guided by your particular production needs and limits:

Type of PCB and Components:

For mainly surface-mount PCBs, AOI would be enough. But if your assembly involves complicated packages, including hidden solder joints like BGAs, then AXI becomes essential for in-depth internal inspections.

Production Volume and Speed:

Inspection by AOI is preferred in a high-volume environment where speed is needed; whereas for low-volume but highly valuable products requiring in-depth analysis, the detailed insight that comes with AXI justifies its slow process.

Budget Constraints:

AOI provides a cost-effective solution with reliable surface inspection capabilities for those manufacturers that are on a tight budget. Once the production complexities increase, AXI may be added to enhance the inspection method by complementing AOI.

Quality and Reliability Requirements:

For example, AXI for internal defect detection is in demand by several industries, like aerospace and medical, that rely on very high-quality standards for their products.

Embracing a Hybrid Approach

Most SMT lines will benefit from a hybrid approach that combines AOI and AXI to leverage the strengths of each method. That way, it ensures fast and cost-effective surface defect detection and provides detailed internal checks. In an overall effective hybrid strategy, AOI on every board post-reflow would be combined with selective AXI only for complex components, striking a balance of cost, speed, and quality for proper defect detection.

Whether to choose Automated Optical Inspection or Automated X-ray Inspection depends on the needs of the production line, considering such issues as the budget and quality. AOI provides speed, cost-effectiveness, and versatility in defect detection of surfaces, making it an attractive option for many manufacturers. The choice of AXI, however, becomes indispensable in complex assemblies where internal quality cannot be compromised with its unmatched capability for probing hidden connections. By understanding the strengths and limitations of each method, it will be possible to develop an inspection strategy that works in concert to create the highest-quality PCB assemblies. Whether implemented solely using AOI, AXI, or a combination of both, the right investment in SMT inspection technology can help boost product quality and increase manufacturing efficiency. At PCBCart, we are committed to supporting your SMT needs with leading-edge solutions and expert guidance to help you achieve uncompromising results in production. Partner with us to elevate your PCB assembly quality to the next level.

Get an Instant Quote for High-Quality PCB Assembly

Helpful resources:

• Printed Circuit Boards Assembly (PCBA) Process – Step by Step

• Why is X-ray Inspection Technology So Important in PCB Assembly?

• Common Defects in PCB Assembly and How to Prevent Them

• How to Get BGA Perfectly Soldered on PCBs in SMT Assembly

• PCB Assembly Inspection Methods: AOI, AXI, ICT and More