In today's electronic design world where time is money, choosing the right Integrated Circuit (IC) package is crucial in optimizing the performance, functionality, and cost-effectiveness of your printed circuit board (PCB). Between the many available packages, Quad Flat No-lead (QFN) and Quad Flat Package (QFP) stand out as popular options with each being tailored to meet certain application requirements. This article is an ultimate tutorial on how to learn these two packaging technologies, comparison of these technologies, and how this will help you choose the appropriate one for your PCB design.

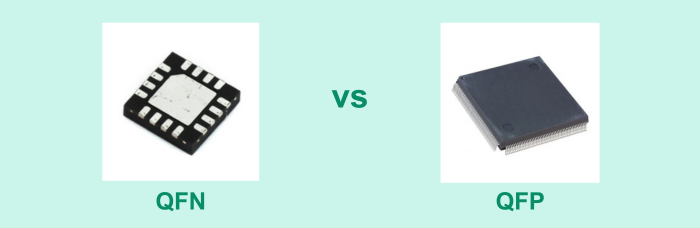

QFN and QFP Packages

QFN Packages: Compact and Inefficient

QFN, or Quad Flat No-lead, packages are characterized by their pin-less design, with the bottom being used with metal pads to make the electrical connection. QFNs' small dimensions, typically between 2x2 mm and 12x12 mm, make them extremely useful in space-limited devices like smartphones and wearables. An exposed thermal pad at the bottom enhances their heat dissipation capacity, making QFNs extremely well-suited for high-performance components where thermal management is a concern.

Structurally, a QFN package is a silicon chip on a substrate that is surrounded by epoxy resin or plastic. The metal pads on the bottom create connections to the PCB, allowing for a small design with efficient use of board space and a reduced footprint.

QFP Packages: Versatile and Robust

QFP, or Quad Flat Package, has another form with 'gull-wing' leads that extend out from the sides. The extending leads facilitate soldering, inspection, and rework. QFPs range in size from 7x7 mm to over 20x20 mm and pin count from 32 to over 200 and are very versatile and used primarily in ruggedness and reliability required applications along with high pin accessibility.

A typical QFP includes a silicon chip and lead frames coated with plastic or ceramic materials. The uncovered leads not only facilitate easy assembly but also facilitate easy visual inspection and testing upon soldering, so QFPs are the delight of industries requiring meticulous quality control.

Key Differences Between QFN and QFP Packages

Lead Configuration:

QFN: Possesses leadless contacts through bottom-side pads, minimizing parasitic inductance and capacitive effects, thus enhancing high-frequency performance.

QFP: With gull-wing leads protruding outward, the packages are simpler to solder and visually examine but may be more likely to produce parasitic effects than leadless packages.

Size and Space Efficiency:

QFN: Ideal for space-restricted designs due to their small footprint. A size-efficient design option for small, high-density electronic designs.

QFP: Although with greater footprints, they provide more forgiving routing options on the PCB, beneficial in designs where board space is not a top concern.

Thermal Performance:

QFN: The exposed thermal pad provides good thermal management, a necessity with high-power application.

QFP: Offers reasonable thermal dissipation characteristics. Even though not as efficient as QFN, optimized packages like HTQFP can offer thermal pads for improved heat management.

Pin Count and Structure:

QFN: Supports moderate pin counts (typically 16 to 80), which are suitable for more straightforward electronic designs.

QFP: Performs well with increased pin counts (usually above 100 pins), which are effective for multi-function, high-order ICs.

Assembly and Inspection:

QFN: More complicated and costly to assemble with hidden joints needing X-ray inspection for quality control.

QFP: Less complex and less expensive to assemble and visually examine with visible leads, streamlining the manufacturing process and repair.

Choosing Between QFN and QFP

It boils down to thinking about your project's particular requirements and concerns:

Use QFN when:

There is limited space and high board density is required.

There is a requirement for high thermal handling because there is high power dissipation.

There is a need for high-frequency performance because there are low parasitic effects.

Use QFP when:

There is high pin count and high I/O connection required.

There is visual inspection ease and rework possibility due to lead exposure.

Your application capitalizes on the ruggedness and reliability of an established packaging form.

Practical Applications and Industry Insights

QFN in Action: Frequently applied in small consumer products like fitness trackers, IoT devices, and smartphones that require space-saving utilization and thermal management.

QFP in Action: Primarily seen in telecommunications, industrial control systems, and automotive electronics where reliability is critical, along with high pin counts and easy rework.

QFN Applications:

Consumer Electronics: QFNs are utilized in smartphones for power management ICs to leverage their compact size and effective thermal dissipation.

Automotive Electronics: Advanced driver-assistance systems (ADAS) utilize QFNs to process high-frequency signals with minimal noise interference.

QFP Applications:

Telecom: Base stations use QFPs in DSP chips since they can accommodate big I/O and simple servicing.

Industrial Equipment: Programmable logic controllers (PLCs) feature QFPs for rugged connections in advanced factory automation systems.

Choosing the right IC package between QFN and QFP depends on considering some design requirements in areas of space, thermal efficiency, pin count, and manufacturing convenience. QFN packages are at an advantage in space-constrained high-performance applications, while QFP packages offer advantages in high-pin-count, inspection-friendly designs.

When it comes to bringing your QFN or QFP-driven designs into reality, PCBCart offers unparalleled expertise and support for PCB assembly and manufacturing. With a track record of achieving high-quality products and services on time and in an efficient manner, PCBCart employs cutting-edge technologies to provide precision in assembly, be it complex QFN soldering or trustworthy QFP connectivity. Our dedication to quality assurance with strict inspection processes ensures dependable performance in your end product. We invite you to discover how PCBCart can help your next project with a competitive quote so that your design becomes a solid, high-performance reality.

Request for Advanced Assembly Solution at PCBCart Now

Helpful resources:

• Optimal Design and Solder Paste Printing Compatible with QFN Component Mounting

• Elements Ensuring Excellent PCB Pad Design for QFN

• Comparison between Ultra Fine Pitch QFP and BGA and Their Development Trend

• Stencil Design Requirement on QFN Components for Optimal Performance of PCBA

• Factors Affecting the Quality of BGA Assembly