The fast development in the electronics sector is still challenging the design and functionality frontiers, as flexible printed circuit boards (FPCs) grow to be a critical aspect of the current technology. FPCs are massively used in the applications of the need of slimness, lightness, and versatility; it is a factor that makes the FPCs perform so well; the type of copper foil applied a choice between the Rolled Annealed (RA) and the Electrodeposited (ED) copper foil. Both of these materials have their own distinctive characteristics, which influence durability, flexibility, and price of the end product, and it is necessary to comprehend their differences and usage. This paper gives a detailed discussion of RA and ED copper foils to facilitate informed choices on the design of flexible circuitry.

RA Copper Foil

Production Process and Properties

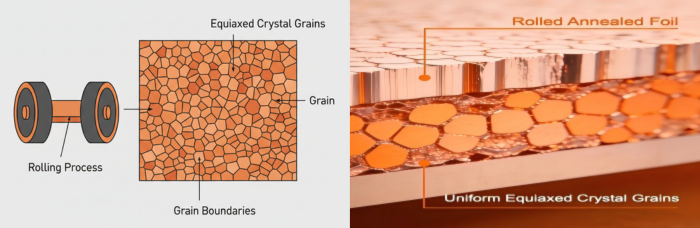

The production of RA copper foil is done by rolling and annealing a copper ingot, repeated pressures and heating are performed to attain the intended thickness. This mechanical process provides an equiaxed crystal structure; the crystal structure improves ductility and smoothness of the foil rendering it very flexible.

Applications and Benefits

Superior Flexibility: RA copper has great flexibility and fatigue strength which will be useful in dynamic applications where circuits must bend or twist and still remain unbroken. This is important in the devices such as foldable smartphones, wearable devices and other electronic products that are exposed to continuous movements.

Surface Smoothness and Thermal Stability: RA copper has a very smooth surface and therefore, this allows significant benefits in the adhesiveness and signal quality, minimizing losses in high-frequency circuitry. Moreover, it is stable under heat and therefore can be used with high temperatures or prices that have a significant number of heat cycles.

ED Copper Foil

Manufacturing Process and Properties

On the contrary, ED copper foil is electroplated such that copper ions are deposited onto a rotating drum to create a layer that has a columnar grain structure. It is an efficient and cost-effective process, which produces copper foil that is less flexible and highly conductive.

Applications and Benefits

Cost-Effectiveness: ED copper production is a cost-effective solution, particularly when used at scale due to its ease of manufacture and scalability. Its application is especially appropriate in case of projects, in which the budget is the main concern.

Adhesion Strength and Mechanical Properties: Although ED copper foil has lower flexibility than RA copper, its rough texture allows a high adhesion rate, which is an advantage in those applications where good bonding to the substrate is essential. It is most applicable to static applications in which circuits are not bent about a lot.

RA vs. ED Copper Foil

Machinery Performance and Flexibility

RA or ED Copper can usually be determined by the need of flexibility:

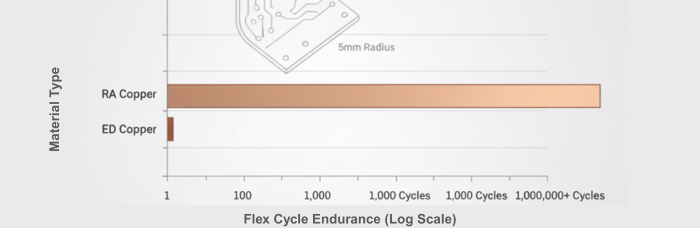

RA Copper: RA copper has a higher capacity than other metals to withstand more than 1,000,000 flex cycles at a 5 mm bend radius, an attribute that makes it the best in projects where high flexibility and resilience is required in the bending. This should make it the best selection in flex dynamic applications.

ED Copper: ED copper is not as flexible, but it is suitable in cases of the stationary application where frequent bending is not necessary. It can usually survive warmer than 1, 000 flex cycles at the same radius of bend.

Cost Considerations

The cost is one of the major determinants when making decisions between the two materials:

ED Copper: It has a great cost benefit because of its efficient manufacturing process and is therefore suitable in low-end manufacturing in which the performance requirement is not strict.

RA Copper: RA copper is more expensive but its investment can be justified in a situation where mechanical stability is a priority and a long-term cost saving due to fewer failures and maintenance can be considered.

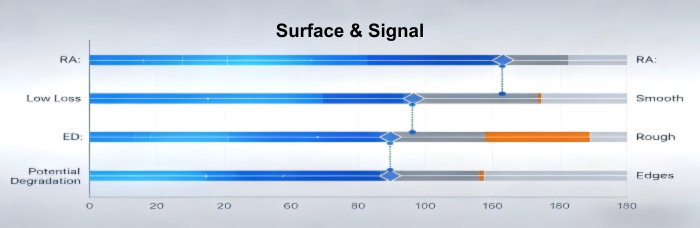

Surface Characteristics and Signal Integrity

RA Copper: RA copper has a smooth surface that reduces signal loss, which is essential in high-frequency and high-precision uses of RF and microwave circuits.

ED Copper: ED copper may not be suitable with RA copper in high-frequency scenarios because its rough surface gives it high adhesion, which may not be desired (as it leads to signal degradation).

Application Suitability

The appropriateness of each type of copper may be appropriate to the particular mechanical and environmental requirements of the use:

ED Copper: Can be used in stationary applications such as automotive lighting system, simple electronics and advertising and displays where cost effectiveness and low movement are the key factors.

RA Copper: Good in dynamic and high stress applications, such as mobile devices, aerospace technology and medical devices that require a high level of mechanical strength and high frequency operation.

The choice of RA and ED copper foils is a critical choice in the design of flexible printed circuit boards (FPCs) with a huge influence on their performance, reliability, and cost. RA copper has a long reputation of being very flexible and thermally stable and hence it is used in dynamic applications like wearable technology and foldable gadgets. The affordability and stability of ED copper in the inactive environment precondition its applicability to the projects with limited budget and low-mechanical requirements. This knowledge of these differences enables the designers and engineers to be able to shape their material selection to suit particular applications.

We are proud to have the best expertise and solutions to your PCB requirements at PCBCart. Having a passion towards quality and innovation, our team is prepared to help you navigate the maze of FPC design so that you can find the right copper foil to use in your project. We offer you detailed consultations and fair quotations as we assist you to balance the performance and budget factors. Worth doing a project with PCBCart the next time you will have the advantage of dealing with one of the industry leaders who have made success in the industry one of its major concerns and meticulously, accurately, and efficiently. Contact us today to quote and optimise your flexible PCB designs.

Get an Instant Quote for High-Quality PCB Assembly

Helpful Resources

• Flexible PCB and Its Assembly Technology

• Guidelines for RF and Microwave PCB Design

• PCB Materials

• Automotive PCB Properties and Design Considerations

• Flexible and Flex-Rigid Printed Circuit Board Applications