The idea of baking in the electronic manufacturing industry goes way beyond food preparation. It is an essential operation in the quality assurance of reliability of printed circuit boards (PCBs) and their parts. With the advancement of electronic devices being more advanced, and smaller in size, it has become necessary to know the procedure necessary to bake PCBs correctly.

Why Baking is Essential to PCBs

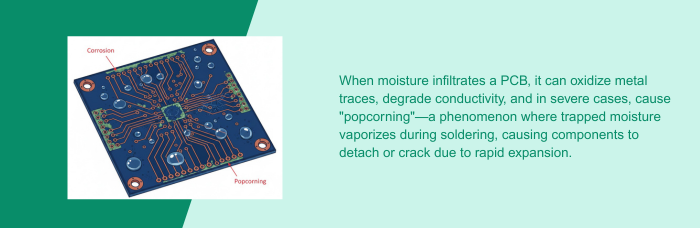

Moisture is a silent enemy of PCBs, being able to bring corrosion, short circuiting, and disastrous failures. The moisture held in a PCB may oxidize the metal traces, causing the board to become low-conductance or even popcorning, where the moisture vaporization may cause the components to loosen during soldering. Moreover, after cleaning with water solutions, PCBs retain moisture, which is worsened by post cleaning with aqueous. Baking is a rather good way to get rid of this unwanted moisture. It will save the unnecessary loss of money and increase the lifespan of the electronic products.

Baking Process

Prepare PCBs

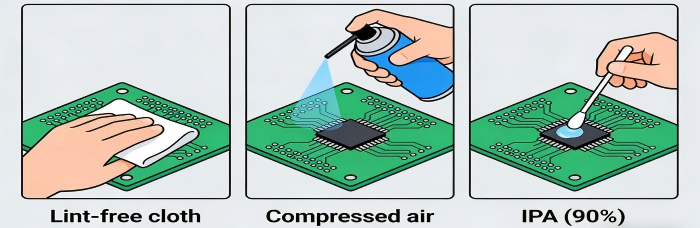

Check your PCB first and then begin the drying process. Wipe it carefully using a lint-free cloth in case it was exposed to any liquid and wipe moisture off in tight places with compressed air. Wipe the board with isopropyl alcohol (at least 90% concentration) as necessary and after that it should be allowed to evaporate.

Select and Prepare the Oven

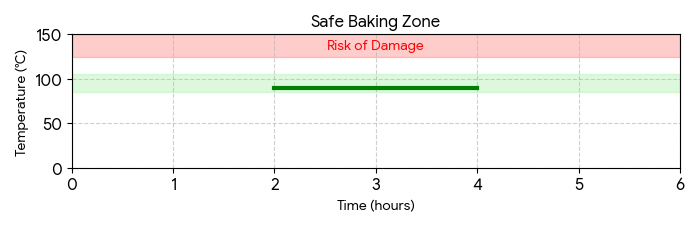

It is important to select the right kind of oven, which is used in drying electronics exclusively, the ovens should not be the ones which are used in preparing food because of the risk of contamination. Warm the oven to a safe temperature of between 85℃ and 105℃, and most PCBs fabricated using standard FR-4 material should be fine with this range. Prepare a heat-resistant tray with parchment paper or silicone mat to make sure there is no conductive contact and prevents scratches or accumulation of electric charge.

Baking PCBs

Place the PCB in a flat position on the tray and do not touch the walls of the oven or overlap the boards in case there are more than one board. Bake 2-4 hours and time varies depending on the size of the board and its difficult nature. Use a fan or a convection mode, where there is one, to ensure uniform heating. Minim the openings of the oven doors so as to ensure that there are no fluctuations in the temperatures and distortions in the drying process.

Cooling and Inspection

With the oven off, allow the PCB to cool therein at least 30 minutes. Slow cooling will avoid thermal shock, and that may be damaging to the board or the components. After cooling, examine the board with regard to any evidence of damage, including any warping or discolouration, which may be a result of overheating.

Best Practices of Temperature and Timing

The baking process is dependent on the sphere of accurately regulating temperature and time:

General Temperature Range: Most FR-4 boards can be used at temperatures of 85℃ to 105℃. Should not be allowed to reach high temperatures more than 125℃ to avoid damaging components or degrading the epoxy resin.

Duration: 2-4 hours are normally enough to effectively achieve moisture removal. In boards containing mounted components, the bottom of this range should be followed to avoid thermal stress of sensitive components.

Part Details: See datasheet of individual parts; some moisture-sensitive parts can need reduced temperature or extended times.

Precautions and Alternative Methods

Baking, though easy, is a careful and safe undertaking:

Avoid Overheating: Still the board or solder joints may melt in case of overheating during the process.

Ensure Ventilation: In the event of the chemical residues, there should be proper ventilation to prevent the inhalation of fumes.

Handle with Care: Wear protective equipment to prevent burns when unloading the tray.

Eliminate Sensitive Parts: It is possible to detach heat-sensitive parts, but make sure that specification is not ignored during the baking.

Baking is also an effective method alternative techniques, like desiccators, compressed air to surface moisture, or low temperature devices like hairdryers to speed up the process. Baking is an all-inclusive, trustworthy option, although each approach has its advantages and disadvantages.

Moisture prevention in Dried PCB storage

It is important to store the PCB properly after baking, to ensure that it is in a moisture-free state. Keep in closed containers with desiccant disks in cool and dry conditions. Moisture-barrier bags vacuum sealed are the best method to protect the product during long term storage to allow future assembly.

Common Mistakes to Avoid

Mistakes may happen even when it comes to a basic technique such as baking. The following traps should be avoided:

Overheating: Do not overheat above 125℃ or you will damage it.

Omission of Cooling Period: Thermal shock can be caused by rapid cooling after baking.

Ignoring Component Specifications: An inability to follow the heat tolerance of components may result in damage.

Crowded Oven Arrangement: The oven should not be overcrowded to provide sufficient space to allow air to flow freely.

Learning how to bake PCBs to dry them is a worthy aspect of the development that provides a precautionary factor to the possible failure of the electronics. It is possible to ensure the credibility of PCBs in different uses providing a clear knowledge of the basic principles, application of specific methods and prevention through the use of measures. Be it a hobbyist or a professional, proper baking is one of the factors that will lead to a successful electronic assembly business, by protecting against the unknown risks of moisture in the constantly changing electronic world.

PCBCart is one of the pioneers in the PCB fabrication and assembly market as far as high quality is concerned. Having a history of accuracy and dependability, PCBCart has a wide variety of services to provide which can be used to satisfy the varied requirements of both electronic manufacturers and hobbyists. Your decision to use PCBCart will mean that you get access to advanced facilities, highly qualified technical support, and quality assurance in all projects. We invite you to request a quote with PCBCart that would make you experience the excellence and efficiency of electronic solutions, which will be developed to take your projects to the new heights.

Request for Advanced PCB Assembly & Manufacturing Quote

Helpful Resources

• How to Ensure the Quality of PCBs

• PCB Protection: Potting or Conformal Coating?

• Moisture Sensitive Devices Storage and Handling