Printed Circuit Boards (PCBs) form the technology backbone of today's electronics, powering everything from smartphones to high-end aerospace systems. As technology continues to advance, there is growing complexity and capability placed on the PCBs. The antiquated hand design and manufacturing methodologies, longtime industry pillars, today are in danger of becoming obsolete by the demands. The coming of smart manufacturing and artificial intelligence (AI) are revolutionizing the PCB industry into a new high-quality development and unprecedented accuracy.

The Intricacies of PCB Design

PCB stands for a platform onto which electronic components are earthed and connected. Through a series of conductive pads and tracks fashioned from copper sheets laminated onto non-conductive substrates, PCBs are the physical structure of nearly all electronic systems. To design them is marked by the formation of schematics, meticulous placement of components, and intricate routing of connections. However, with the emergence of technologies like 5G, Internet of Things (IoT), cloud computing, and artificial intelligence (AI), the demand for PCBs has surged, driving complexity to unprecedented levels. Modern designs need to offer increased component density and connectivity in confined areas, giving rise to the requirement of sophisticated design to prevent interference in signals and other potential errors. Relying on repeated models of traditional design methodologies is time-consuming and prone to long lead times.

AI: Transforming PCB Design Processes

AI is transforming the PCB designing process by making it more precise, quicker, and more efficient. By leveraging strong pattern recognition and intelligent analytics, AI systems are able to greatly reduce human error in the designing process and greatly reduce time-to-market with automation. Not only are they optimization tools, but they are learning tools as well, that assist in building skills and transferring knowledge between engineering teams.

Significant advancements introduced through AI are:

Automated Component Placement: Optimal component placement is commonly achieved through time-consuming trial and error to reduce signal crosstalk and heat dissipation. AI algorithms reduce this to seconds by examining design constraints and past data to propose optimized layouts, maximizing performance and reliability.

Innovative Routing Solutions: Routing around dense components is one of the toughest aspects of PCB design. AI employs sophisticated algorithms to automate this process, considering design rules, interference avoidance, and manufacturing constraints to produce efficient routing methodologies. AI solutions consistently beat human-created designs in innovation and efficiency.

Simulation and Error Minimization: AI-driven simulation analysis enables signal integrity to be simulated and analyzed prior to physical prototyping of a design. This has the potential to significantly minimize the need for costly redesigns, converting the traditional manual, iterative process of design into an optimal, automated process.

By integrating AI with conventional design tools, such as CAD systems, the productivity of PCB designers is significantly increased. AI allows for the immediate analysis of thousands of design solutions, selecting best-of-breed configurations that were previously impractical to explore due to time and labor considerations.

AI's Impact on Manufacturing and Inspection

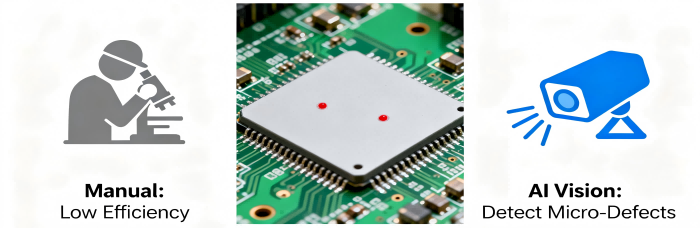

The AI revolution crosses boundaries to the PCB manufacturing and inspection fields, promising significant productivity as well as quality control gains:

Better Inspection Techniques: Traditional manual inspection techniques are inherently less than efficient and laborious. AI, through advanced computer vision technology, can inspect and detect microscopic defects with high accuracy through deep learning algorithms before products reach the factory gate. This results in a significant improvement in product quality.

Optimized Process and Waste Minimization: By the analysis of live sensor data from production equipment, AI dynamically optimizes manufacturing parameters to maximize yields and minimize waste. It also identifies production constraints, guiding investments into necessary system upgrades, thereby making the manufacturing pipeline leaner and more agile.

Predictive Maintenance: With the combination of AI and IoT sensors, predictive maintenance is enabled by forecasting equipment failure prior to it occurring. This forward-looking strategy reduces expensive downtime and increases operational uptime and equipment utilization.

Smart Factories and Industry 4.0

Intelligent factories reflect the vision of Industry 4.0, integrating mechanisms like automation, IoT, and AI in each stage of production. Intelligent factories interconnect machines, software, and humans as an integrated system based on data. Manufacturing execution systems (MES) make production statistics, defect percentages, and workflow congestion real-time visible and also enhance the efficiency of operations.

Automation in PCB manufacturing is evidenced in the application of SMT placement machines, robotic arms, and automatic optical inspection (AOI) systems, all purposed in eliminating the reliance on manual work.

Overcoming Challenges and Embracing Future Trends

Although encouraging progress is observed, the application of AI in PCB technology is not without challenges. Challenges such as insufficient quality training data, lack of cross-disciplinary expertise, and AI model transparency challenges need to be addressed. Similarly, smart factories are faced with challenges such as high initial investment, complexity of merging MES/ERP systems, and cyber threats. To address these, the industry will need to invest in workforce development, build robust data-sharing architectures, and build collaborative ecosystems.

Future advancements will further identify AI-driven process optimization as the backbone of production lines, employing machine learning algorithms to scan real-time data and dynamically optimize. Digital twin technology will allow simulating and testing processes, equipment operating time, and risk assessment prior to production occurring. In addition, advancements like 3D printing of printed circuit boards and self-healing circuits will have the potential to redefine even more possibilities in mission-critical applications such as aerospace systems.

The integration of intelligent factory technology and AI is revolutionizing the entire process of making PCBs, from design to testing. Design loops are reduced for engineers, manufacturers achieve higher yields, and businesses achieve lower costs and higher reliability. This synergy of AI-driven intelligence and human expertise is optimizing an industry previously held back by human capabilities.

At PCBCart, we are at the forefront of this revolution. Join with us and learn how AI and smart manufacturing can enhance your PCB manufacturing. Contact us today for tailor-made solutions expressly designed to meet the needs of your particular application and industry.

Get an Instant Quote for Advanced PCB Assembly

Helpful resources:

• PCB Technological Innovations and Application Practices Driven by 5G and AI

• Intelligent Manufacturing

• Simulation Using OrCAD PSpice

• What Future PCB Will Be Like

• Effective Measures to Defeat Warpage Problem for PCBs

• Five Modes of Intelligent Manufacturing and Their Requirement