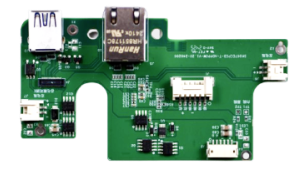

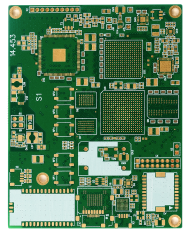

PCB AssemblyHOT

One-stop PCB assembly service.

read more

Fulfillment: Turnkey or consigned

Quantity: 1-10,000+pcs.

Quality Grade: IPC3

Lead time: as short as 2 days

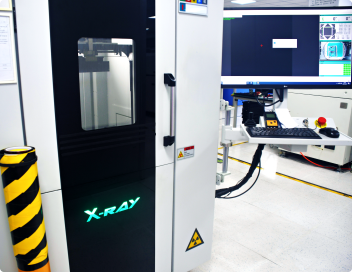

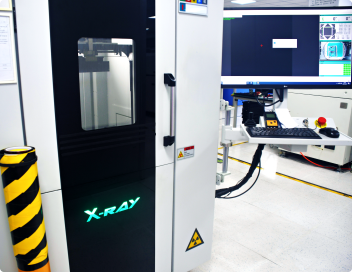

Other: AOI, X-ray, SPI, ICT

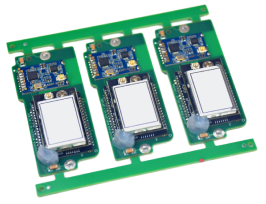

PCB Prototype

Quick-turn prototype PCB with low cost.read more

Layers: 1-8

Quantity: 5-1000 pcs.

Quality Grade: Standard IPC 2

Lead time: 2-9 days

Material: FR4

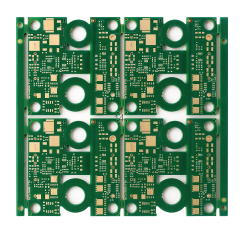

Standard PCB Fab

Full feature FR4 PCB fabrication.

read more

Layers: 1-32

Quantity: 1-1million pcs.

Quality Grade: Standard IPC2

Lead time: 2 days-5 weeks

Material: FR4

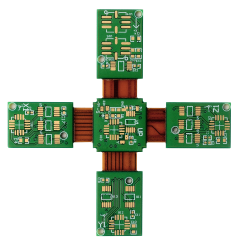

Advanced PCB Fab

Complex PCBs leading to your applica-tions’ best performance. read more

Layers: 1-32

Quantity: 1-1million pcs.

Quality Grade: Standard IPC3

Lead time: 12-15 days

Type: Flex, Rogers, Alu, etc.

PCB Layout

Optimize your designs with our precision PCB layout services read more

Layers: Up to 64

Capability: Support 150,000+ PIN

Services: Validation and re-engineering

Lead time: 3-10 days

Type: Rigid, Flex, Rigid-Flex, HDI

BOX Build Assembly

Ready-to-ship electronic products,

tailored to your needs.

read more

Simple to multi-component systems

Tailored to your specifications

ISO9001, IATF16949, RoHS, UL

Cable/harness & electro-mechanical assembly, testing, packaging

Turnkey PCB Assembly Services

PCB Services

PCB Services

Quality

Assurance

Customer

satisfaction

Secure

Transaction

PCB Manufacturing

PCBCart offers full-feature PCB production services with high reliability to be fully compatible with your requirement.Business covers rigid FR4 PCBs, HDI PCBs, FPC, Aluminum PCBs, Rogers PCBs, etc. Learn More

- Expanded manufacturing capabilities

- Rigorous quality control options

- Value-added options: FREE DFM and more

- Online quote and order system

PCB

Assembly

Short

lead time

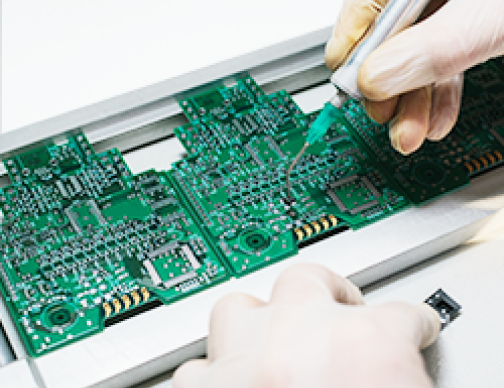

PCB Assembly

Covering PCB fabrication, parts sourcing, SMT and/or THT assembly, PCBCart's one-stop turnkey PCBA services can be flexibly combined to meet your project's scope,quality, schedule and budget needs. Learn More

- 01005, 0201, 0.4mm pitch BGA

- AOI, X-ray, FAI, Flying probe

- Certified components sourcing

- Box build assembly, IC programming

PCB Assembly Capability

PCB Assembly Capability

Advanced PCB Fab Capability

Advanced PCB Fab Capability

PCBCART

PCBCART Thailand Factory Officially in Operation

PCB Assembly Facilities Showcase

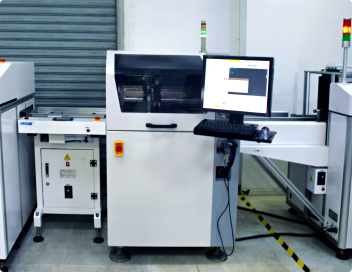

Advanced Equipment and Testing

Jet Printer and Dispenser (MYCRONIC)

3D AOI

High-Speed 3D Solder Paste Inspection System

High-Precision Solder Paste Printer

JTR-1200D-N Reflow Oven

KED600 Batch Cleaner

SE-450-HL Wave Soldering System

Panasonic NPM-W2 Chip Mounter

X-RAY

ZSWHPS-11-2 Selective Wave Soldering Machine

3D AOI

High-Speed 3D Solder Paste Inspection System

High-Precision Solder Paste Printer

JTR-1200D-N Reflow Oven

KED600 Batch Cleaner

SE-450-HL Wave Soldering System

Panasonic NPM-W2 Chip Mounter

X-RAY

ZSWHPS-11-2 Selective Wave Soldering Machine

Automated Production Line: Features the latest automatic three-proof paint spray and dispensing machines to meet diverse processing needs.

Comprehensive Testing Process: All quick sample products undergo 100% automatic optical inspection (AOI), visual checks, and X-ray testing before shipment.

Why Choose us

With 20 years of dedication and innovation, PCBCart stands as a top PCB manufacturing supplier, offering exceptional PCB Assembly and Layout services tailored to meet your specific needs with high quality and precision.

Singapore

Singapore

Parkview Square, Singapore

Parkview Square, Singapore

Thailand Factory

Thailand Factory

Samut Prakan Province, Thailand

Samut Prakan Province, Thailand

USA

USA

Katy Houston

Katy Houston

China Factory

China Factory

Hangzhou, China

Hangzhou, China

Prepreg vs. Core in PCB Manufacturing

Choosing PCBCart optimizes prepreg and core material usage in PCB design, enhancing structural integrity, performance, and efficiency.

view detailsHow to Optimize Microvia Drilling, Copper Plating, and Filling for HDI PCBs?

Learn practical strategies to optimize microvia drilling, copper plating & filling for HDI PCBs—enhance performance, reliability, and manufacturability with industry standards.

view detailsRigid-Flex PCB Assembly Process

Rigid-flex PCBs combine rigidity and flexibility, offering unmatched compactness and reliability crucial for advancing electronic technologies in diverse industries.

view details