This article will tell you nothing but the introduction of SMT (Surface Mount Technology) assembly procedure and its development trend in the future.

PCB successfully added to your shopping cart

As the Chinese New Year holiday is approaching, please note that our office will be closed from February 14th to 23rd (10 days). During this period, responses to inquiries may be delayed, but you can still submit quotes and orders online as usual.

English

English

English

English

English

English

Español

Español

Deutsch

Deutsch

Français

Français

Italiano

Italiano

日本語

日本語

ภาษาไทย

ภาษาไทย

Malay

Malay

This article will tell you nothing but the introduction of SMT (Surface Mount Technology) assembly procedure and its development trend in the future.

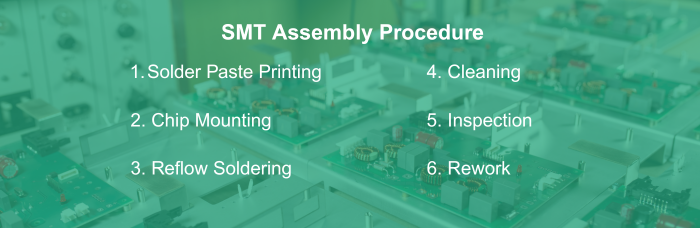

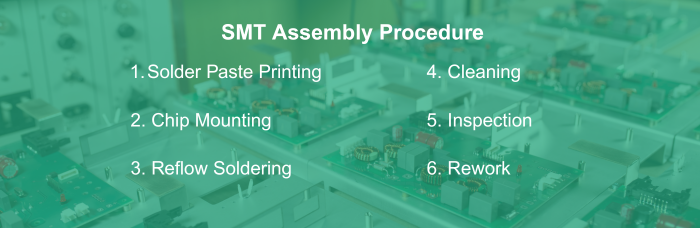

SMT assembly procedure primarily consists of the following steps: solder paste printing, chip mounting, reflow soldering, cleaning, inspection and rework, all of which will be introduced in detail below.

• Solder Paste Printing

Solder paste printing refers to the process in which solder paste is placed onto PCB (Printed Circuit Board) pad through the openings on stencil. Solder paste printing is implemented by solder paste printer that is placed at the first beginning of SMT assembly manufacturing line.

• Chip Mounting

Chip mounting aims to place components onto corresponding positions on PCB compatible with design files and it is done on chip mounter that is placed after solder paste printer in SMT assembly manufacturing line.

• Reflow Soldering

In the process of reflow soldering, solder paste is first melted, making SMCs (Surface Mount Components) or SMDs (Surface Mount Devices) stuck to PCB board with solder paste cooled down. Reflow soldering is carried out in reflow soldering oven that is placed after chip mounter in SMT assembly manufacturing line.

• Cleaning

Cleaning aims to eliminate hazardous residues left on board. Hazardous residues possibly derive from flux that is used during reflow soldering process. Cleaning machine is usually used to clean off residues, which is not placed at a fixed position in SMT assembly manufacturing line. Cleaning can be implemented either during SMT assembly line or off the line.

• Inspection

Inspection is used during SMT assembly procedure to get the quality of soldering and assembly guaranteed compatible with corresponding manufacturing standard and regulations. Numerous equipment and tools can be used to participate in SMT inspection, such as magnifying lens, microscope, ICT (In-circuit Tester), Flying probe test, AOI (Automated Optical Inspection), X-ray inspection, function tester etc. Inspection equipment can be placed on any suitable position if necessary.

• Rework

Rework is implemented to fix or remanufacture PCB whose defects are exposed through inspection. To implement rework, some equipment and tools are called for, including electric soldering iron, rework station etc. Rework can be placed at any position of SMT assembly line.

Development Trend#1: Quick, Flexible and Fast-Responsive

Competition in the future will become so drastic that any successful corporation has to depend on quick, flexible and fast-responsive technical equipment system. As long as that aim is obtained, more opportunities will be captured to enter market and more profit will be made. Therefore, SMT machinery will develop towards quick, flexible and fast-responsive direction in the future.

It’s been known that SMT assembly manufacturing line grows from single equipment to multiple equipment line so that volume production can be improved. High efficiency has been an essential target people have been striving for and SMT manufacturing efficiency is indicated by productivity efficiency and control efficiency. Productivity efficiency refers to the comprehensive productivity of all the equipment along SMT assembly manufacturing line and higher productivity derives from appropriate allocation. In addition, high-efficiency SMT manufacturing line has already developed from single-line manufacturing to double-line manufacturing, which not only reduces covered area, but also improves manufacturing rate.

Development Trend#2: Green and Environment-Friendly

It has to be admitted that SMT assembly manufacturing line has to some extent done great harm to the environment, from applied material such as package material, solder paste, adhesive agent, flux etc. to SMT assembly procedure. The more SMT assembly manufacturing lines there are and the higher their levels are, the more serious the damage will be. As a result, future SMT assembly manufacturing line will develop towards green line.

Green manufacturing refers to the fact that requirement concerning environmental protection has to be achieved at the very beginning of SMT assembly manufacturing. Possible pollution source and extent should be carefully analyzed that will be exposed in each procedure of SMT assembly manufacturing so that corresponding SMT equipment and material can be picked up, manufacturing regulations made and manufacturing condition established. Finally, the SMT assembly manufacturing will be administered in such a suitable, scientific and reasonable way that manufacturing requirement and environmental protection can be obtained. Therefore, both manufacturing scale and manufacturing capacity should be considered in terms of SMT assembly manufacturing. Besides, the effect brought by SMT assembly manufacturing to environment should be compatible with environmental protection demand, from design, SMT manufacturing line establishment, SMT equipment determination, material selection etc.

Development Trend#3: High-Efficiency and Intelligent

When it comes to surface mount technology, the upgrading and development of SMT equipment indicate the level of SMT assembly. Manufacturing efficiency will become an important standard to mark the performance of SMT equipment in the future. To improve manufacturing efficiency, some adjustment has to be made in terms of SMT equipment structure and some improvement has to be made in terms of SMT equipment performance.

Another development trend of SMT equipment lies in its flexibility that leads users to customize their service based on their differentiated demands and requirement. Additionally, modularization can be used to cater to different functions to meet mounting demands from different components and mounting should be implemented on different accuracy and speed so that the overall manufacturing efficiency can be increased.

As a new type of electronics assembly technology, SMT has been widely applied in all sorts of products covering numerous fields. Due to its own attributes and advantages, SMT has partially or completely replaced traditional electronics assembly technology, leading to essential and revolutionary changes in electronics industry. Therefore, it’s of necessity to get aware of SMT assembly procedure and its development trend in the future to make it better serve industries.

SMT assembly is a vital part of modern electronics, including processes like solder paste printing, chip mounting, and reflow soldering to deliver consistent, high-quality devices. Current trends emphasize speed, flexibility, and environmental sustainability, placing SMT at the forefront of innovation and efficiency. Keeping abreast of the trends is necessary in order to fully benefit from the technology.

PCBCart possesses the most modern technology and expertise to support your SMT assembly needs. Our commitment to quality and innovation ensures your projects meet future as well as current demands. Partner with PCBCart for solutions that optimize performance and sustainability in your manufacturing operations. Contact us today for a detailed quotation and experience the advantages of working with a leading industry expert.

Receive Your Instant SMT Assembly Quote Today]

Helpful Resources

• Design Requirement of SMT PCBs Part One: Bonding Pad Design of Some Ordinary Components

• Design Requirement of SMT PCBs Part Two: Settings of Pad-Trace Connection, Thru-Holes, Test Point, Solder Mask and Silkscreen

• Design Requirement of SMT PCBs Part Three: Component Layout Design

• Design Requirement of SMT PCBs Part Four: Mark

• Full Feature PCB Manufacturing Service from PCBCart - Multiple Value-added options

• Advanced PCB Assembly Service from PCBCart - Start from 1 piece

PCBCart specializes in high-complexity, precision PCB assembly for mixed-volume batches, offering full-service electronic manufacturing excellence since 2005.

PCBCart specializes in high-complexity, precision PCB assembly for mixed-volume batches, offering full-service electronic manufacturing excellence since 2005.

[email protected] [email protected]

[email protected] [email protected]

Thanks for your support! We'll go over your feedback in detail to optimize our service. Once your suggestion is picked up as the most valuable, we'll instantly contact you in email with a $100 coupon contained.