The need to have smaller, faster and more complex devices is increasing in the modern rapid electronics manufacturing industry. Surface Mount Technology (SMT) assembly has been the key process to address these requirements. The most important part of the SMT assembly is the pick and place machine, which is also a very sophisticated machine that has transformed the way components are placed in its accuracy and speed.

Working Principle of Pick and Place Machine

Pick and Place machines are highly complex robots created to automate the placement of surface-mounted devices (SMDs) on to printed circuit boards (PCBs). They work in an intensively designed SMT assembly line in which several pre procedures are used to make sure that the components are placed successfully.

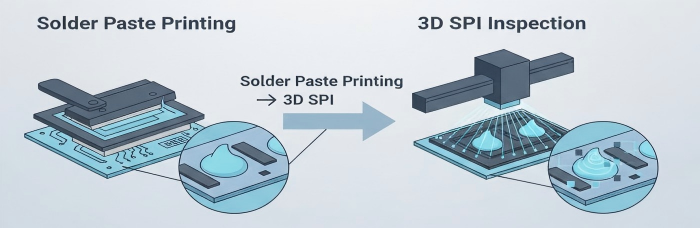

Preparation and Inspection

The PCB should be well-prepared prior to the initiation of pick and place process. The PCB is then sprayed with solder paste which is a compound of small balls of solder and flux created through the use of a stencil printer. This application should be very precise because this is the factor that directly influences the quality of connection between the component. The 3D Solder Paste Inspection (SPI) machine performs a check after the application to identify any variation of the paste volume and positioning. This is to make sure that only boards that are well prepared go to the next step.

The Pick and Place Process

Component Pickup: The system is a pick and place machine that is provided with feeder systems that organize and deliver components arranged in reels, trays, or tubes. Such systems expose the placement head to the components repeatedly and at precise time, which is important in reducing errors when performing operations at high speeds.

Check and Adjustment: Developed vision devices are used where high-resolution cameras are used to image every component. The systems check the type and orientation of the component and align them before putting them to position. This is a very important step in dealing with different package sizes, including tiny ones such as 0201 or even smaller.

Component Placement: The machine part that is referred to as the head of placement picks up and lays the components onto the particular solder paste applied pads on the PCB. The accuracy of this process cannot be overemphasized because it defines the quality and the performance of the board assembled. Linear motors and encoders can operate at high speed which helps to gain required accuracy and speed.

Advantages of Pick and Place Machines

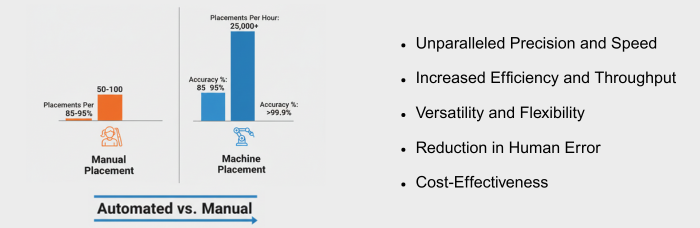

Incomparable Accuracy and Rapidity: Pick and place machines are able to do thousands of placements per hour, which is much more than can be done by human labour. This accuracy guarantees that complex parts like Ball grid arrays (BGAs) will be perfectly aligned with the PCB pads preventing problems like misalignment and tombstoning.

Greater Productivity and Response: Automation of the component placement process leads to substantial efficiency and time savings on the production process. Machines are also consistent in terms of large production runs and this is important in ensuring that quality in terms of quality is met.

Versatility and Flexibility: These types of machines are able to accommodate an enormous number of different sizes and shapes of components, with the manufacturers able to readjust to different design requirements without any issues. This scalability will aid in small scale as well as mass production without huge reconfiguration.

Minimization of Human Error: Pick and place machine reduce the possibility of human error by automating what is usually a labor intensive task. The result of this automation is increased reliability and reduced defective products.

Cost-Effectiveness: Although pick and place machines require a significant amount of money at the beginning, cost advantages are huge in the long-term. This involves reduction of the labor expenses, reduction of the wastes and streamlining of the production processes.

Implication on Electronics Production

Pick and place machines have revolutionized the electronic manufacturing process, as the complex electronic products can now be manufactured in high speed and precision. They play a critical role in satisfying the consumer needs of the high-technology products at competitive prices.

Trends and Advancements

The pick and place machines improve with advancement in technology. The current developments involve the incorporation of artificial intelligence (AI) and machine learning to extend the powers of machines. AI will enable machines to be able to maximize the placement routes and anticipate maintenance requirements, thereby cutting down on downtime and increasing returns.

Moreover, with components becoming smaller than 01005 in size, it is now developing machines with refined nozzles and sensitive vision systems. This adaption enables them to work with exceptionally small and sensitive elements, and be accurate to the changing circumstances.

A second trend includes the shift towards a smart factory-setting. It is an integration of real-time data analytics, which can predict maintenance and correct errors in real-time. The flexibility and efficiency of manufacturing can also be considerably improved since, due to smart factory settings, switching between various production runs can be done in a short period.

To conclude, pick and place machines have been indispensable in the current SMT assembly procedure and have allowed unmatched accuracy and velocity in the placement of surface-mount devices on PCBs. The machines help simplify production by automating the placement of components which are very efficient, flexible and accurate. With the ever-growing technological progress, these machines will come with more developed capabilities including AI and machine learning, further increasing their abilities. This development has made it possible to enable manufacturers ease the continuously increasing demands of smaller and more sophisticated electronic gadgets without compromising the quality of production and economical processes.

At PCBCart, we have invested in state-of-the-art pick and place machines to ensure that our clients enjoy premium PCB assembly services. Our commitment to precision, combined with cutting-edge technology, enables us to guarantee quality and reliability in our services. We are dedicated to helping you improve your production lines through our innovative processes, hence maintaining a competitive advantage in the industry. Visit our website today and request a quote to experience our exceptional PCB assembly services.