In the field of electronic manufacturing, PCBs can be assembled through several means, which significantly affect the performance, reliability, and cost of the finished product. Whether you are prototyping your design or scaling up for mass production, determining between manual and automated assembly is one of the most important choices that would greatly influence your profit margin. At PCBCart, we know that each project is different and the best approach might be determined by production volume, budget, or design complexity. This article will explain both the manual and automated PCB assembly processes, thus providing insight into how best to make your decision.

Understanding PCB Assembly and Its Importance

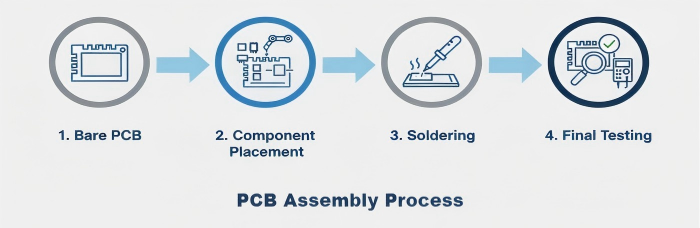

PCB assembly is a very complex process for attaching electronic components on a printed circuit board to make the electronic device functional. The assembly methods directly influence production speed, error rates, and overall cost. Failure to match your assembly methods with your production needs results in inefficiency, increased costs, and delays. A careful understanding of manual and automated methods will help in selecting the most apt approach.

Manual PCB Assembly: Flexibility and Precision

Manual PCB assembly requires skilled technicians to place and solder components on the board using hand tools and soldering irons. Although labor-intensive, this approach has its own advantages in particular situations.

Advantages:

Flexibility for Customization: Manual assembly works especially for PCB prototyping, where frequent design changes are still at a high level. Technicians can easily readjust, without any time-consuming reprogramming of equipment, and provide needed agility during early stages of development.

Lower Initial Costs: In the case of low-volume production, manual assembly eliminates the major setup costs required by automated systems, thus making the process more economically viable in cases involving smaller quantities.

Handling Complex Designs: Some PCBs contain non-standard components or special handling, such as heat-sensitive parts. It ensures manual assembly of these intricacies with the required precision.

Disadvantages:

Slower Production Speed: It is naturally slower compared to other methodologies, like automation, and hence ill-suited for higher volumes of production.

Higher Error Rates: The risk of human error, like misaligned components or inconsistent soldering, could lead to concerns about the product's quality and reliability, potentially creating 1-2% or more in error rates per board.

Expensive for Large Volumes: Labor costs scale directly with the size of the order, and doing it by hand is not economically viable when the order volume is very large.

Manual assembly tends to be preferred for startups or engineers in initial designs where flexibility is more important than speed.

Automated PCB Assembly: Speed and Efficiency

Fully automated PCB assembly utilizes special equipment, such as pick-and-place robots and reflow ovens, in placing and soldering components with very little human labor. This method is optimized for efficiency, especially in larger production runs.

Advantages:

High Speed and Scalability: Automated systems can handle upwards of thousands of components per hour, reducing production time considerably for high-volume orders and thus reducing time to market.

Consistency and Precision: Machines ensure uniform component placement and soldering; error rates as low as 0.01% are realized, which is important to ensure high product quality.

Cost-Effective for Large Runs: While the initial costs are higher, economies of scale reduce per-unit costs in large productions and save significantly over manual methods.

Disadvantages:

High Initial Investment: Automation setup can be quite costly, with costs ranging from programming and machine calibration to possibly special tooling.

Limited Flexibility: Any design changes or modifications require reprogramming, adding to the cost and generally extending the lead times, hence not ideal for projects in flux.

Not Efficient for Small Batches: In low-volume runs, setup costs often negate any benefit derived from automation, making manual assembly the more pragmatic option.

Large-scale production, where speed and consistency have a direct bearing on profitability and assurance of quality, is generally best suited to automated assembly.

Choosing the Right Method: Key Scenarios

PCB Prototyping: Manual Assembly is Best

During prototyping, designs are subject to change, making manual assembly the better choice. Since only a minimal number of units is required, manual processes keep costs low, allowing for fast changes without the associated downtime related to the reprogramming of automated systems.

Low Volume Production: Consider a Hybrid Approach

Manual and hybrid methods are appropriate for production runs between 10 to 250 units. The hybrid method is a balanced approach wherein automated systems are used for standard components, while manual skills are resorted to for special parts; the approach balances cost and quality optimization.

High Volume Production: Automation is the Key

In large-scale scenarios, when the production is more than 1,000, automated assembly is inevitable. This process offers substantial cost benefits not only through lower per-unit costs but also due to the rapidly growing production efficiency that is positive for competitiveness.

Cost Analysis and Implications

Cost is usually the deciding factor. Here's a simplified breakdown based on industry averages for a standard 2-layer PCB with 50 components:

Prototyping (1-10 Units): For the relatively high setup costs in automation, manual assembly is cheaper.

Low Volume (100-250 Units): The costs begin to balance. Automation is more feasible if setup fees amortize across enough units.

High Volume (1,000+ Units): Automated assembly offers substantial savings through per-unit cost cuts and accelerated production schedules.

Quality and turnaround are the decisive factors. Automated systems have lower defect rates and take less time in assembling. Still, manual assembly can be quicker for urgent small-batch orders.

In the competitive field of electronics manufacturing, the choice between manual and automated PCB assembly has a big impact on cost, quality, and turnaround time. With its unbeatable flexibility and precision, manual assembly is well adapted to the PCB prototyping and low-volume production runs where design changes are frequent. On the other hand, automated assembly performs exceptionally in high-volume production by guaranteeing speed, consistency, and cost-efficiency. Understanding the strengths and weaknesses of each method, the manufacturer could fit his production strategy according to his project requirements and ensure maximum performance with an optimal budget.

At PCBCart, we are committed to guiding you through the complexities of PCB assembly with precision and expertise. Whether you are embarking on a small-scale prototype or preparing for a large-scale production run, we offer comprehensive solutions that cater to your unique needs. Our state-of-the-art facilities support both manual and automated assembly, guaranteeing that you receive the highest standard of quality and that the latest technological innovations are available to you. Partner with us for seamless manufacturing processes, competitive pricing, and exceptional customer support. Get in touch with PCBCart today for a quote and take the first step toward a successful PCB project.

Get an Instant Quote for High-Quality PCB Assembly

Helpful resources:

• How Much Does PCB Assembly Cost: A Complete Guide From Basics to Optimization Approaches

• Differences Between PCB Prototyping and Full Spec Production

• 6 Effective Ways to Cut PCB Assembly Cost Without Sacrificing Quality

• Why More and More Customers Choose PCBA One-Stop Service