For the electronics manufacturing industry, PCB (Printed Circuit Board) assembly is the fulcrum point that binds design to finished goods. Its cost has a direct impact on project budget planning, product pricing strategy, and a company's marketplace competitiveness. Irrespective of whether you are a novice to the business or an experienced one seeking cost reduction, it is imperative that you know thoroughly the composition, determinants and control mechanisms of PCB assembly costs. This manual provides you with an elaborate and logically consistent overview of PCB assembly costs.

1. Fundamentals and Operations of PCB Assembly

1.1 What is PCB Assembly?

PCB assembly refers to the process of installing and connecting electronic components (e.g., resistors, capacitors, integrated circuits (ICs), connectors) to a bare PCB using specified technologies, which yields a working electronic assembly. It is the most important phase of the conversion of "bare boards" into "finished products" in electronic device manufacturing, and it influences the performance and reliability of the device directly.

1.2 Major Assembly Technologies and Processes

PCB assembly technologies are largely divided into two groups, with vast differences in processes and usage:

- Surface Mount Technology (SMT) Assembly

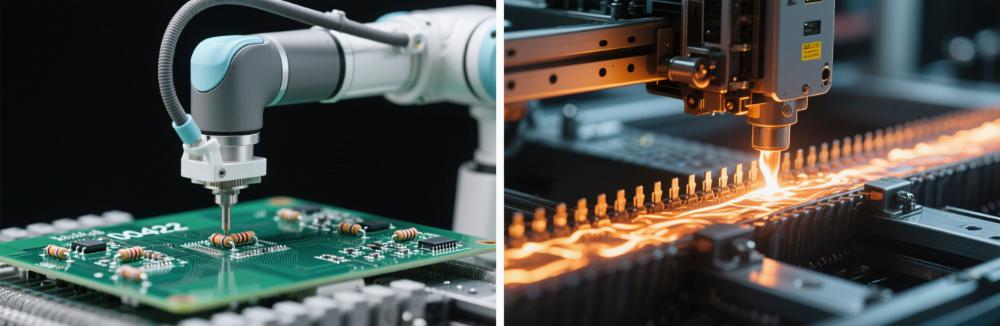

It is the mainstream technology of modern electronics manufacturing, well suited to miniaturized, high-density electronic products. Its core processes are:

- Solder Paste Printing: Printing solder paste onto designated pads on the PCB using a stencil or printer ahead of future soldering.

- Component Placement: Using high-accuracy pick-and-place machines to select SMT components and accurately place them onto the solder-paste-coated pads according to design requirements.

- Reflow Soldering: Conveying the PCB with components mounted into a reflow oven, where solder paste melts and solidifies using accurately controlled temperature curve cycling, forming a solid electrical bond between pads and components.

- Inspection: Through the use of Automated Optical Inspection (AOI) and other methods for checking component position accuracy and quality of solder joints, to ensure assembly quality.

SMT technology is very automatable, suited for mass production, and reduces unit cost significantly, making it desirable for miniaturized high-density designs.

- Through-Hole Technology (THT) Assembly

It is well-suited to apply in mounting components requiring high mechanical strength or high power handling, with relatively complex processes:

- Hole Preparation: Pre-drilling of holes in the PCB prior to component insertion with precise diameters matching component leads.

- Component Insertion: Manual insertion or machine insertion of component leads through pre-drilled holes into place over pads.

- Soldering: Use of wave soldering and other methods to solder component leads onto pads on the other side of the PCB, forming electrical and physical connections.

- Inspection: Verification of soldering quality and component installation accuracy by visual inspection or functional testing.

THT technology involves higher man power involvement, is suitable for low-volume manufacturing or special component assembly but with relatively higher costs.

- Hybrid Assembly Technology

The majority of advanced electronic devices combine the advantages of SMT and THT technologies to achieve a hybrid assembly process. On the same PCB, for example, small and low-power components use SMT, and THT uses large and high-power components while having an equilibrium among performance, cost, and reliability.

2. General Range of PCB Assembly Prices

PCB assembly prices have a wide range depending on various factors. It is helpful to have the following ranges in mind in order to budget ahead of time:

2.1 By Area

The estimated cost of PCB assembly is normally $0.02 to $0.05 per square inch, with typical labor and indirect cost. Actual costs in the real world will, nevertheless, vary widely based on design complexity, material selection, and other factors.

2.2 By Single PCB

- Small PCBs (size: 2x2 inches to 4x4 inches): Approximately $5 to $20 per board based on design complexity.

- Small PCBs (size: 4x4 inches to 6x6 inches): Approximately $10 to $30 per board, based on component density, layer number, etc.

- Large PCBs (size: 6x6 inches and bigger): Between $20 and hundreds of dollars per board, primarily due to larger material consumption and complexity in processing.

2.3 By Assembly Technology

- SMT Assembly: Approximately $50 to $500 per panel, best suited for high-density, mass-produced boards.

- Through-Hole Assembly: Approximately $100 to $1,000 per panel, more costly due to more labor-intensive than SMT.

- SMT + Through-Hole Hybrid Assembly: Approximately $150 to $1,500 per panel, between the two figures based on the percentage of each technology used.

2.4 By Production Volume (Unit Cost)

Unit costs are very production-volume sensitive, with economies of scale being obvious:

| Production Volume Range | Unit Cost (USD) | Explanation |

| 1-10 units | 50-200 | High fixed cost proportion leads to high unit costs. |

| 10-100 units | 20-100 | Costs start to be diluted. |

| 100-1000 units | 10-50 | Economies of scale begin to show. |

| 1000-10000 units | 5-30 | Unit costs decrease significantly. |

| 10000+ units | 2-20 | Fixed costs are fully diluted. |

3. Key Drivers of PCB Assembly Cost

Variations in PCB assembly cost are caused by the interaction of multiple factors; complete knowledge of these factors is the origin of cost control:

3.1 Material Selection: Ideal Cost vs. Performance

Materials form the basis of cost, and fluctuations in material cost and performance directly determine end costs:

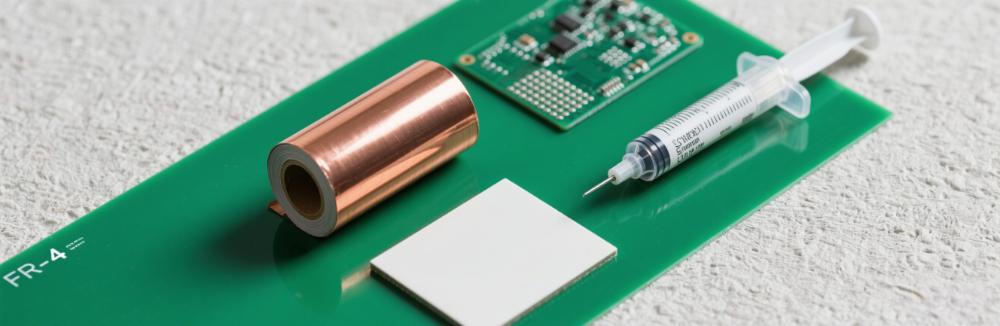

- Substrate materials for the PCB

Substrate material selection must be optimized between cost and performance requirements:

- FR-4: Common cost-effective material, ranging from $1.00 to $8.00 per square foot, for general-purpose electronic products with favorable mechanical strength and electrical properties.

- Ceramic: Ranging from $5 to $50 per square foot, having favorable high-temperature endurance and high-frequency capability, for high-reliability applications such as aerospace and military.

- Elastomeric materials (such as polyimide, PTFE): Between $2 and $20 per square inch, flexible, for special uses like wearable devices and foldable displays.

- Copper Thickness

The copper layer thickness will affect the current-carrying capability, thermal dissipation efficiency of PCBs, and cost:

- Thin copper (1 oz to 2 oz): $5 to $20 per square foot, covering the current and heat dissipation needs of standard electronic devices.

- Thick copper (4 oz and above): $20 to $50 per square foot, higher strength conductivity and heat dissipation with increased material and processing cost, suitable for high-power devices but costlier.

- Solder Paste

Quality of solder paste directly affects solder joint reliability with great price differences:

- High-end solder paste: $40 to $80 per syringe or jar with high wettability and stability, reducing solder joint defect rates.

- General or lead-free solder paste: $20 to $50 per syringe or jar with relatively low performance but acceptable for applications where low reliability is acceptable.

3.2 PCB Design Parameters: Size, Thickness, and Complexity

- Size

PCB size affects material usage and processing complexity as well. Small PCBs for electronics in watches, for example, are less expensive than large ones for desktop computers or industrial hardware since they use less material and are simpler to process. The packing density of components on the PCB also has an impact on costs—the denser the component packing, the higher the processing precision required, and thus the expense.

- Thickness and Aspect Ratio

While the impact of PCB thickness on costs used to be negligible, it has increasingly been important in recent years with the increase in complex designs:

- Thin PCBs (0.8mm or thinner): Approximately $10 to $30 per board, and with very little material utilization and relatively simple processing.

- Thicker PCBs (2.0mm and above): Approximately $15 to $40 per board or higher; if they also have a high aspect ratio (length-to-thickness ratio), processing complexity increases dramatically, and costs increase.

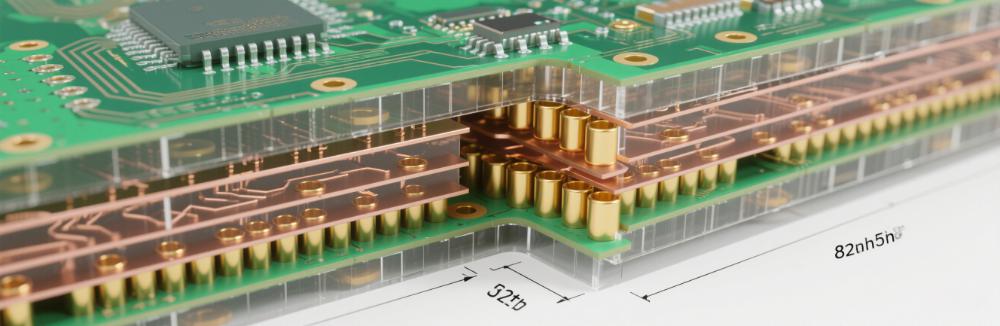

- Number of Layers

Number of layers is a key cost driver. Multilayer PCBs (for example, 4-layer, 6-layer, 8-layer) provide more wiring space by adding signal and ground layers, suitable for complex circuit schematics. Additional layers, though, mean higher material costs and extra lamination steps, and result in significantly increased costs. For example, 4-layer PCBs can range from 30% to 50% more expensive than 2-layer PCBs.

- Design Complexity

Design complexity is reflected in component density, signal routing, etc.:

- Component density: Denser component structures are more demanding for placement equipment concerning precision, leaving less time for manual adjustments and inspections and, as a result, with higher costs.

- Signal routing: High-frequency, high-speed signal routing should not be affected by interference and crosstalk and should employ advanced design tools and technologies, which drive up design and manufacturing expenditures.

3.3 Component Types and Assembly Technologies

- Component Types

Different forms of components have varying impacts on assembly costs and processes:

- Surface Mount Devices (SMDs): Small in size (e.g., 0402, 0201 packages), very suitable for automatic insertion, at a lower cost.

- Through-hole components: Larger in size, semi-automatic or manual insertion, with lower efficiency in assembly and higher cost, very appropriate for use where high power or mechanical strength is required.

- Advanced packaging components (e.g., BGA, CSP): With tall and dense pins, requiring special assembly and soldering machines (e.g., X-ray inspection equipment), most expensive.

- Assembly Technologies

The choice of assembly technology directly affects costs:

- SMT: High automation, well suited for volume production, with low cost per unit but high initial equipment investment.

- THT: High manual labor, suitable for special assembly of small lots or parts, with high unit costs.

- Hybrid assembly: A mix of the best of both technologies, and cost being somewhere in between both of them, depending on component proportion and design complexity.

3.4 Production Volume and Lead Time

- Production Volume

The impact of production level on cost is most notably achieved in economies of scale. With an increase in production level, fixed costs such as debugging equipment and training personnel are spread across more units of products, considerably reducing their unit cost. An example is that the unit cost of producing 1000 PCBs would be 50% lower compared to producing 10 PCBs.

- Lead Time

Typical lead times (7-14 days) allow manufacturers to plan production moderately at the least expense; rush orders (2-3 days) have added costs, typically 10%-30% of the standard cost, for overtime labor, priority equipment scheduling, and expedited logistics.

3.5 Testing and Quality Control

Testing and quality control are significant connections to assure PCB performance, and their investment has a direct impact on costs:

- Basic testing (e.g., visual examination, simple functional testing): Low in cost, approximately $0.1-$2 per board.

- Advanced testing (e.g., Automated Optical Inspection (AOI), In-Circuit Testing (ICT), X-ray inspection): High in cost but can detect small defects with high precision, reducing subsequent rework and after-sales costs, ideal for products with high reliability standards (e.g., medical equipment, automotive electronics).

4. The Importance of PCB Assembly Costs: The Link Between Quality and Price

PCB assembly costs are not just about price but are directly related to product quality, reliability, and competitiveness in the marketplace:

4.1 Component Position Accuracy

More costly assembly solutions inevitably utilize high-precision placement equipment (e.g., high-precision pick-and-place machines), enabling exact component placement, reducing faults such as solder joint defects and component misplacement, and ensuring minimum device functionality. Less costly solutions usually do not have sufficient equipment accuracy, resulting in unreasonably high defect rates and increased subsequent rework costs.

4.2 Soldering Quality

Soldering is the most important process in PCB assembly; quality soldering relies on quality solder paste and experienced engineers. Costly solutions invest more in the soldering process, forming strong and stable solder joints, avoiding hazards like cold solder joints and fake solder joints, and reducing the chances of electrical failure during device usage. Costly solutions invest low-quality solder paste or inexperienced engineers, resulting in poor solder joint reliability and affecting device lifespan.

4.3 Comprehensive Inspection and Testing

Solutions that cost more necessarily involve more stringent inspection and test processes. For example, AOI may check for placement faults in components, and ICT can check for circuit connectivity so defects are detected early in production and corrected to ensure only qualified products are put into circulation. Less costly solutions can relax inspection processes, so defective products get passed into circulation and brand image is ruined.

4.4 Leverage of Newest Technologies

More costly solutions can use advanced technologies such as SMT, with the ability to support finer and denser package sizes of components for the miniaturization and high-performance functioning of electronic devices to fulfill the development needs of modern consumer electronics and IoT devices.

4.5 Compliance and Certification

Certain industries (e.g., medical, aerospace) are accompanied by rigorous standards and PCB certification requirements (e.g., IPC standards). More costly solutions involve the expense of meeting such standards, rendering products industry compliant and market accessible. Less costly solutions can also be non-compliant, excluding products from target markets.

5. Methods of Estimating PCB Assembly Cost

Estimating PCB assembly cost to the best of one's capability keeps in mind a number of components; the following are some methods:

5.1 Total Cost Formula

Total Cost (C) = Component Cost + Labor Cost + Indirect Cost + Material Cost + Testing and Inspection Cost + Quality Assurance Cost

5.2 Detailed Calculation of Individual Cost Components

- Component Cost: Find the cost of purchase of all electronic components applied in the PCB, i.e., resistors ($0.1-$1 per unit), capacitors ($0.1-$2 per unit), integrated circuits ($1-$10 per unit), connectors ($0.1-$5 per unit), etc. Total component cost is the sum of all component prices.

- Labor Cost: Calculated on the basis of the complexity of design and assembly technology. SMT assembly labor stands at $15-$30 per hour, and professional or prototype assembly (with complex components such as BGA) at $20-$50 per hour. Multiply with working hours to arrive at the total labor cost.

- Indirect Cost: It includes rental of production facilities, equipment depreciation, utilities, management wages, etc., typically estimated at 20%-40% of the total cost.

- Material Cost: Cost of non-component auxiliary materials such as PCB substrates, solder paste, and flux, based on material type and application.

- Testing and Inspection Cost: Basic functional testing is estimated at $0.1-$2 per board; complex testing (e.g., AOI, ICT) is estimated in terms of use of equipment and man-hours.

- Quality Assurance Cost: The cost of additional testing and documentation to meet industry standards or customer requirements, estimated according to specific requirements.

5.3 Calculation of Unit Cost

Unit Cost = Total Cost ÷ Number of Assembled PCBs. For example, if the total cost is $1000 and 100 PCBs are assembled, then the unit cost is $10 per board.

6. Effective Strategies for Reducing the Cost of PCB Assembly

Assuming the maintenance of quality, the following actions can effectively reduce PCB assembly cost:

6.1 Simplify PCB Design

- Smeet Design: Assuming meeting functional functions, reduce PCB layer number (e.g., 4 layers to 2 layers), reduce component density, remove unnecessary complex structures, and reduce processing steps and materials consumed.

- Reduce Through-Hole Count: Through-hole processing adds additional drilling and soldering operations; reducing through-hole count can reduce labor and equipment costs.

- Use Standard Parts: Emphasize universal, easily available standard parts, reduce special or custom-made parts, and reduce procurement cost and inventory control complexity.

6.2 Reasonably Schedule Production Quantity and Ship Time

- Increase Order Quantity: Leverage economies of scale to reduce unit costs by ordering in large volumes. Raising an order from 100 boards to 1000 boards can reduce unit costs by 30%-50%.

- Choose Standard Lead Times: Avoid rush orders, produce responsibly, and utilize standard lead times to minimize additional charges.

6.3 Select Appropriate Assembly Technology

- For mass production, high-density PCBs must prioritize SMT technology to reduce unit cost with its automation advantage.

- For low-volume or special through-hole components PCBs, hybrid assembly technology can be utilized as a cost-performance compromise.

6.4 Choose Cost-Effective Suppliers

- Multiple Suppliers Comparison: Compare prices, services, and quality of different suppliers and determine cost-effective partners.

- Evaluate Supplier Capability: Choose suppliers with advanced equipment, experienced technology, and strict quality control to reduce cost of rework due to low quality.

- Purchase Value-Added Services: Opt for those suppliers that offer value-added services such as design consulting, procurement of components, and after-sales services in an effort to reduce project costs overall.

6.5 Design for Manufacturability (DFM)

Collaborate closely with assembly suppliers at the outset to utilize PCB design to the supplier's production ability and process characteristics, avoid manufacturability issues in the design, and reduce follow-on modification and rework costs. For example, coordinate component spacing with the supplier's placement machine accuracy to maximize production efficiency.

7. Key Considerations in Selecting a PCB Assembly Supplier

The choice of a good PCB assembly supplier is crucial for quality and cost control; take note of the following:

7.1 Quality and Reliability

- Check if the supplier has passed industry certification such as ISO 9001 and IPC, and whether it has strict quality control processes in place (e.g., full-process inspection, traceability systems).

- Find out the supplier's defect rate (PPM) index; choose suppliers with low defect rates to avoid high rework costs later.

7.2 Technical Capabilities and Equipment Level

- Determine whether the supplier has the required assembly technologies (e.g., SMT, THT, hybrid assembly) and can handle complex components (e.g., BGA, micro-components).

- Understand the equipment status of the supplier, such as placement machine precision, soldering machine capability, and inspection equipment types; high-end equipment is the cornerstone of quality and efficiency guarantee.

7.3 Experience and Professionalism

- Choose suppliers with long-term experience in the target industry (e.g., consumer electronics, industrial control, medical electronics); they are familiar with industry standards and special demands and can provide more professional services.

- Evaluate the supplier's engineering team capability to establish if they are in a position to provide design optimization suggestions to reduce cost.

7.4 Communication and Responsiveness

- Choose suppliers with effective communication and quick response, who are able to feedback production status in a timely manner and resolve issues, avoiding delays due to information lag.

- Understand the supplier's project management process to ensure projects are delivered on time and to quality.

7.5 Cost Transparency

- Request suppliers to provide a complete cost breakdown (e.g., component fees, processing fees, testing fees) to avoid hidden fees.

- Compare the quoting structure of different suppliers and select partners with reasonable and transparent pricing.

8. Commonly Asked Questions Regarding PCB Assembly Costs

8.1 What are the most effective factors in PCB assembly costs?

The most important influences are: PCB design complexity (number of layers, size, component density), component type and number, assembly technology, quantity produced, test requirements, and lead time.

8.2 Which is more cost-effective: SMT assembly or through-hole assembly?

In general, SMT assembly is more cost-effective, especially in large-volume production. SMT is characterized by high automation and low unit cost; through-hole assembly is more expensive with more manual involvement, suitable for special circumstances.

8.3 How significant is the cost difference between small-batch and large-batch orders?

The difference is considerable. As an example, the unit cost of 10 PCBs can be 5-10 times more than that of 1000 PCBs because large-batch orders can dilute fixed costs.

8.4 How much additional cost must be paid for rush orders?

Typically 10%-30% of normal costs, depending on the urgency and supplier policy; fees pay for overtime labor, priority use of equipment fees, and expedited shipping fees.

8.5 What proportion of the total cost of electronic products does assembly cost constitute?

It typically accounts for 30%-60%. The proportion is lower for simple products, but complex products (e.g., smartphones, industrial controllers) have a higher proportion due to more components and complicated processes.

8.6 How to verify if a cost quotation from a supplier is reasonable?

You may request the supplier to provide a detailed breakdown of the costs, compare the quotation structure of multiple suppliers, and conduct an overall analysis based on the quality of the supplier, technical capabilities, and industry reputation.

9. Conclusion

PCB assembly costs are a core link in electronics manufacturing, with their level affected by multiple factors such as materials, design, technology, and production volume. Understanding the mechanism of these factors and mastering cost estimation and optimization methods can help enterprises effectively control costs while ensuring quality, enhancing market competitiveness.

Practically, both cost and quality should be balanced—too low costs can lead to compromises in quality, and too high costs affect profitability. By design optimization, rational planning of production volume, selecting appropriate technology and suppliers, the optimal point of balancing cost and quality can be achieved to clear the way for electronic project success.

No matter if you are a rookie or an experienced veteran in the industry, closely monitoring fluctuations in the cost of PCB assembly and continually optimizing cost control measures are crucial to setting up and growing in the business of electronics manufacturing.

Get an Instant PCB Assembly Quote

Helpful resources:

• PCB Assembly Process

• What is Surface Mount Technology (SMT)?

• Through-Hole Technology in High-Speed PCB Design

• DFM for PCB Design

• PCB Quality Inspection

• Common Defects in PCB Assembly and How to Prevent Them

• How to Evaluate a PCB Assembler