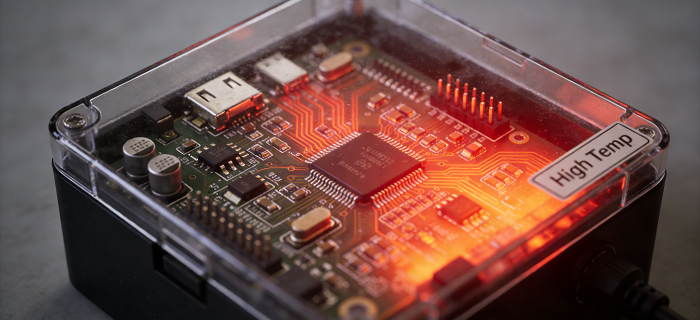

Picture having to hold a scalding mug for hours - uncomfortable, impossible to sustain, and eventually damaging to your hands. Now picture a PCB driving a high-powered device, generating watts of energy in a small enclosure with no means of dissipating the ever-building heat. Overheating has become one of the most critical threats to PCB reliability as electronics continue to shrink in size, surge in performance, and proliferate in numbers. When a PCB runs too hot, it doesn’t just fail to deliver performance - it triggers an avalanche of destruction that degrades functionality, reduces lifespan, and can even result in complete system failure. Let's dig into the unseen repercussions of PCB overheating and why proactive thermal management is non-negotiable for any electronic design.

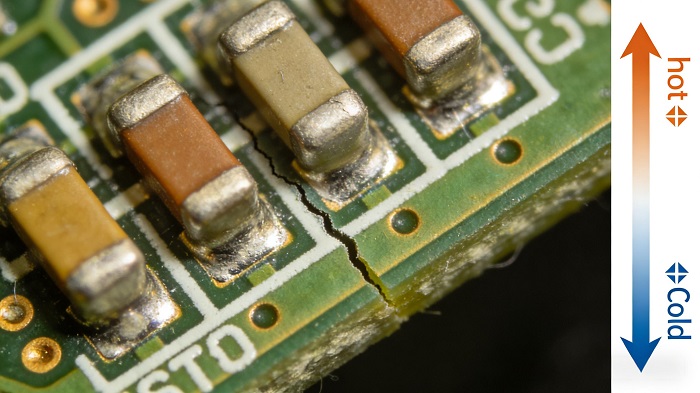

First, it targets the PCB’s physical interfaces. This starts at the solder interfaces, or lifelines, between the board’s components and the board itself. The truth is that each material found on a PCB, from the board material itself to the solder material and the components, expands when heated. However, they expand at rates that are wildly different from each other. This results in continuous stress as the board is constantly cycled through heating and cooling. The resulting strain, as the solder interfaces expand and contract, results in the development of tiny cracks, detaching, or complete fracturing of the solder. This is particularly exacerbated by thermal cycling, which causes the component pads on the board to become detached. The most alarming aspect is that this usually happens out of sight, while inside, the board is literally holding its Dignity Together.

Excess heat is also a hidden accelerator of component degradation. Extended periods of high temperatures reduce the life of electronic components by increasing overall component wear, leading to problems such as electromigration (the gradual movement of metal atoms caused by an electric current, causing a reduction in conductive paths) and dielectric breakdown (insulation breakdown in components separating electrical circuits). Even components engineered to work in high temperatures will fail; they lose efficiency, become slow, and fall short of an average life span. However, when components undergo thermal runaway, it becomes a self-reinforcing process in which increasing temperatures escalate leakage currents and resistances, which in turn cause an increase in overall component heats until it leads to catastrophic failure within seconds.

A loss of performance is another direct victim of overheating. Contemporary PCBs have thermal protective mechanisms that turn off or reduce the clock speed when overheated, protecting the circuitry from any harm. However, when proper cooling is absent, these protective mechanisms are reached much sooner. A fast processor might be slowed down to half speed, or it might start spewing out erroneous data—it has nothing to do with the sensors’ performance, as the PCB isn’t able to cool down quickly enough. Adding fuel to the flames are the so-called hot spots, where temperature buildup is erratic, centered on power-hungry components.

Signal integrity—essential to accurate device function—fails when extreme temperatures are encountered as well. Temperature affects chips in such a way that resistors change from their nominal value, capacitances decrease in capacitors, and semiconductors change conductivity. As a result, timing, biasing, and signaling go out of focus, causing data corruption, oscillations, and incurring complete failure in communications. Copper tracks on a PCB, being a copper path connecting devices on a PCB, are also prone to such problems when they lift from a PCB or separate due to an overload of heat, creating hidden problems in a PCB that are quite difficult to debug before it leads to complete failure.

The catch? These issues can be mitigated with proper design and thermal design consideration. Methods such as integrating thermal vias to direct heat away from critical areas, using heat sinks with high thermal-conductivity thermal pads, optimal component placement to prevent overcrowding heat sources, adding in natural convection by way of ventilation, and increasing the size of the copper pours to provide well-rounded heat distribution are all effective in doing so. For more extreme conditions, high-end options in the form of ceramic substrate materials or liquid cooling solutions are available.

But it has to begin with choosing a manufacturer who can expertly navigate the complexities of PCB design with thermal resistance in mind. This is where PCBCart can help. PCBCart boasts over two decades of design expertise for high-reliability PCBs that can withstand the rigors of high-performance applications such as industrial control applications, consumer electronics products, automotive applications, medical applications, and so forth. At PCBCart, thermal performance is given utmost priority from design conceptualization onwards. Our experienced teams work with yours to ensure that it can overcome the odds of miniaturization, high power density circuits, and handling high ambient working conditions with ease.

Heat shouldn't stop you from achieving your project. Trust us at PCBCart, where we can convert your design into a strong, heat-resistant solution that can fulfill all your demands. Get in touch with us today to see more about our expertise in handling heat.

Request for High-quality PCB Assembly & Fabrication Quote

Helpful Resources

• PCB Thermal Design Considerations

• Metal Core PCB an Ideal Solution to Thermal Issues

• The Most Comprehensive Principles of Thermal Design for PCBs

• Design of High-Power PCB in High Temperature Environment

• Internal Thermal Dissipation Design of PCB based on Thermal Model

• Effective Measures to Defeat Warpage Problem for PCBs