Soldering is a very crucial process in PCB assembly and manufacturing, which is highly essential in ensuring functionality and reliability in electronic assemblies. The soldering process involves joining the SMD and PTH components to the PCB through the use of solder as the conductive medium. However, different types of soldering defects might occur, and all these have a great deal of impact on the quality of the final product.

Common Soldering Defects and Their Effects

Understanding the different types of soldering defects is important to detect and address them effectively.The main classes of defects, considering their failure modes, are:

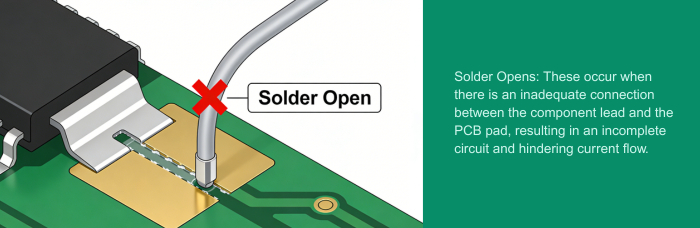

Open Circuits

Solder Opens: These solder opens happen when there is not enough connection between the lead of a component and the pad of a PCB, incompletely opening a circuit and hindering the flow of current.

Lifted Pads: This is when excessive heat and mechanical vibration causes the PCB pad to detach, which leads to loss of connection.

Solder Skips: These happen when solder is not applied to the pads of SMDs, hence leaving areas unsoldered with open circuits.

Short Circuits

Solder Bridges: When excess solder bridges between conductors on the PCB and creates unwanted connections, short circuits arise.

Solder Balls: These are the small, stray spheres of solder on the surface of a PCB, potentially causing shorts when lodged between conductors.

Solder Splash: Unwanted solder droplets due to impurities or contaminants can cause shorts.

Loose Joints

Cold Solder Joints: Poor heating during the time of soldering resulted in weak joints that are characterized by a rough, dull surface.

Disturbed Joints: Movement during soldering may inhibit proper bonding, leading to failure to ensure reliability.

Solder Voids: Spaces in the solder joint weaken the connection due to contamination or lack of wetting.

Insufficient Solder: Results in a joint with little electrical or mechanical integrity.

Other Defects

Solder Dewetting: This is when the solder does not adhere properly to either the PCB pad or the component lead.

Solder Flux Residue: Residual flux has the potential to cause corrosion or problems with insulation resistance.

Solder Cracking: Due to stress or thermal cycling tends to degrade strength and conductivity at the joint.

Tombstoning: One end of a component lifts off the pad during reflow because of uneven heating.

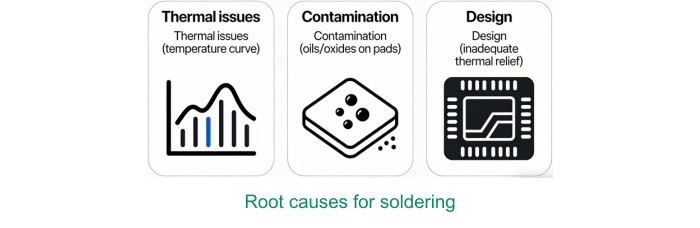

Causes Behind Soldering Defects

The only way to effectively prevent soldering defects is to identify the root causes:

Thermal Issues: Lack of heat or too-fast cooling yields cold joints and voids.

Solder Quantity: Too much solder produces bridges. Insufficient quantity yields opens.

Contamination: Oils, oxides, or chemicals on surfaces can impede proper soldering.

Missing Alignment of Components: Incorrect placement can include defects such as tombstoning.

Design Defects: Inadequate thermal relief and poor design of the pad are also causes for various defects.

Excessive Thermal Shock: Temperature extremes can cause pads to lift and crack.

Solder Paste Quality: Low metal content and other factors can lead to solder balling and solder bridging.

Prevention Strategies for Soldering Defects

Prevention of soldering defects needs control in design, material selection, process optimization, and inspection:

Design for Manufacturing

Provide adequate spacing between conductors to prevent bridging.

Provide generous thermal relief in pad designs to help avoid tombstoning.

Ensure that the size of components matches pad layouts for correct fitting.

Validate designs through prototyping and functional testing.

Solder Paste Controls

Provide high-quality solder paste that is suitable for the assembly process.

Check quality of solder paste application on a regular basis.

Store solder paste to adhere to expiration dates.

Clean the stencils and monitor the quality of apertures.

Process Controls

Optimize the reflow oven settings for the ideal thermal profile.

Control cooling rates to avoid thermally-induced defects.

No-clean flux or clean the PCBs thoroughly after soldering.

Monitor key process parameters such as temperature and conveyor speed.- Train operators in proper techniques of soldering.

Inspection Techniques and Repair

A strong inspection and repair system can greatly reduce the impact of soldering defects:

Methods for Inspection

Visual Inspection: It is a good method for observing obvious defects with magnification tools.

AOI: The technology makes use of high-resolution cameras to inspect a number of different manufacturing defects, such as soldering defects.

X-Ray Inspection: Due to the fact that most hidden defects occur in multilayer or compact PCBs, the X-ray method of inspection is ideal in this situation.

Electrical Testing: Continuity and functional tests ensure that there is proper connectivity.

Solderability Test: Evaluates the quality of the joint by shape and contact angles.

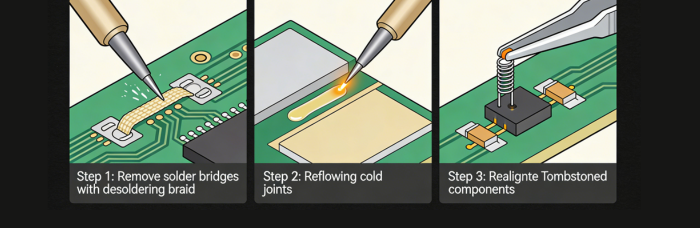

Repair Techniques

Solder Bridges: Remove excess solder using a soldering iron or braid without damaging nearby joints.

Cold Joints: Reflow the joint, providing adequate heating for proper wetting.

Solder Balls: Carefully remove using suitable tools to avoid component damage.

Edge alignment: realign elements to their correct positions.

Tombstones: Realign components accurately to correct positions.

Lifted Pads: Reattach pads using appropriate adhesives. Replace the board if needed.

Solder Voids: Avoid voids by using proper reflow but avoid overheating the PCB.

Flux Residue: Need manual or automated cleaning using the most suitable solvent.

Soldering is one of the basic processes in PCB assembly and manufacturing. It is very important to ensure functionality and reliability in electronic devices. However, soldering defects related to open and short circuits, weak joints, and other anomalies can render the product of low quality.This guide has discussed common types of soldering defects, their root causes, and the best practices for their prevention. Employing effective design for manufacturing (DFM), optimizing process controls, and embracing optimal inspection and repair techniques can help manufacturers reduce incidences of such defects and hence improve their product quality and reliability.

At PCBCart, we value the importance of precision and quality in PCB manufacturing. As one of the leading PCB manufacturers and assemblers with one-roof service, we pledge to deliver superior products through the application of strict quality control measures, utilizing the latest technologies in our processes, including wave and reflow soldering. Our responsible team ensures every step in the production chain is carefully monitored to avoid defects and ensures your PCBs will meet the highest criteria for reliability and performance. Contact us today for a quote and make PCBCart your reliable partner to perfection in your electronic assemblies.

Get an Instant Quote for High-Quality PCB Assembly

Helpful Resources

• Process Control Measures to Stop Defects in SMT Assembly

• PCB Manufacturing Process — A Step-by-Step Guide

• How to Solve Solder Joint Problems in SMT Processing?

• How to Ensure the Quality of PCBs

• Common Defects in PCB Assembly and How to Prevent Them