In the complex world of PCB design and electronic manufacturing, one is often brought to the important decision of opting between hard gold plating and soft gold plating. The choice here is not about selecting a surface finish but strategically enhancing performance, durability, and reliability in electronic components.

Understanding Gold Plating in Electronics

Gold plating is the depositing of a thin layer of gold on electronic components, usually through electroplating, because of its high electrical conductivity, corrosion resistance, and signal integrity. Not all gold plating is the same, though. Hard Gold Plating involves alloying gold with metals like cobalt or nickel to increase its durability, while Soft Gold Plating is nearly pure, enhancing electrical conductivity. These differences lead to distinct applications and advantages suitable for various mechanical and environmental challenges.

Hard Gold Plating

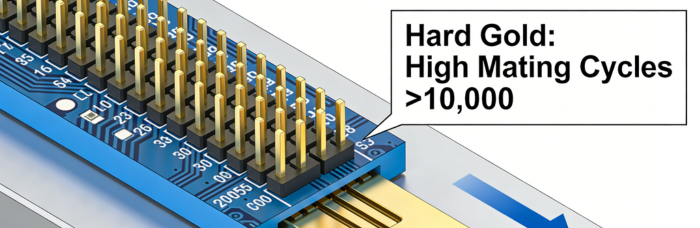

The composition of hard gold, usually alloyed with 0.1–0.3% Co or Ni, features hardness between 120 and 300 Knoop. This composition is provided by electrolytic deposition over a nickel underlayer. The increased hardness of hard gold enables it to withstand thousands of mating cycles-more than 10,000 in edge connectors. It also resists scratches in high-contact environments with stable contact resistance over the life of the connector.

Typical Thickness and Cost: Hard gold has an approximate thickness of 0.75–1.25 µm; the durability will increase with greater thickness, but costs go up substantially as well. Thus, it is used on a select basis, often just on card-edge fingers, while the rest of the board uses a different finish such as Electroless Nickel Immersion Gold (ENIG).

Advantages and Applications: Hard gold is extremely durable and wear-resistant, being particularly suited for sliding or mated contacts in high-insertion applications. Being resistant to vibration and repeated use, it provides stable electrical contact. Typical applications are PCB edge connectors, backplane cards, switch and relay contacts, and areas of high wear in industrial, telecommunication, and defense equipment.

Limitations: Despite the fact that, although advantageous, hard gold is less conductive than pure gold because of alloying. Additionally, it is not suitable for soldering or wire bonding since thick layers of hard gold may result in brittle solder joints. It is also more expensive when large areas or thick layers are required.

Soft Gold Plating

Composition and Hardness: Soft gold plating is almost pure gold, generally ≥99.9% Au, and has very little alloying to provide a hardness of 60–85 Knoop. This makes it much softer and more ductile than hard gold. It often shows up in the manufacturing of PCBs and substrates as soft electrolytic gold over nickel for wire bond pads, or as part of ENIG/ENEPIG finish systems in which the gold layer is thin but pure and flat.

Typical Thickness and Cost: Soft gold for bonding typically has a thickness of 0.1–0.3 µm; immersion gold layers are thinner, about 0.05–0.1 µm for ENIG/ENEPIG. These thin layers make soft gold cost-effective per unit area, particularly for dense surface-mount technology and bond pads.

Advantages and Applications: Soft gold provides the best electrical conductivity to ensure minimum signal loss of high-frequency circuits. It has excellent corrosion resistance, which is useful for high-reliability design in harsh environments. Besides, its excellent bondability makes it perfect for gold or aluminum wire bonding in IC packaging and RF modules. The purity and flatness of soft gold ensure controlled impedance and consistent performance in both high-frequency and high-speed circuits.

Limitations: Soft gold's primary weakness is low wear resistance; it often fails after only a few hundred mechanical cycles. It is prone to scratching and deformation during handling if not carefully controlled, making it unsuitable for high-friction or frequently mated connectors.

Hardness as the Key Technical Divider

The greatest technical differences among hard and soft gold include hardness, which correlates directly with their applications. Hard gold provides a hardness rating of about 120–300 Knoop, alloyed for wear resistance and slightly reduced conductivity from pure gold; thus, it serves best for contacts and connectors. Soft gold, at about 60–85 Knoop in hardness, is highly conductive but also more apt to scratch or otherwise deform, thus serving best for wire bonding, high-frequency pads, and corrosion-critical areas.

Making the Right Choice for PCB Design

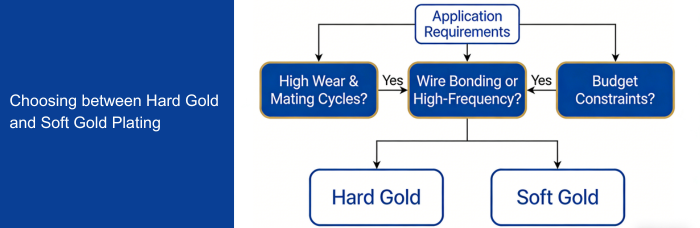

The choice between hard and soft gold relies on several critical factors:

Application Type: Hard gold is used for components such as connectors, switches, edge fingers, and pogo-pin test pads with high cycles, while soft gold is preferred for bonding pads, RF/microwave circuits, high-speed digital, and corrosion-critical nodes.

Mechanical Environment: If the surface is subjected to vibration, or frequent mating or sliding contact, the durability of hard gold becomes essential. Static solder joints, fixed wire bonds, and low mechanical stress environments are areas where soft gold excels.

Electrical Performance: The higher conductivity and flatness of soft gold provide advantages in ultra-low loss and tight impedance control. Where slight conductivity differences are of no consequence, as in standard digital interconnects, either type, if applied correctly, will be satisfactory.

Compatibility of the Assembly Process: Wire bonding or delicate microelectronics assembly requires soft gold or ENEPIG, while connector-intensive assembly and rugged handling demand hard gold on contact areas.

Budget and Finish Strategy: Hard gold can become costly over large areas and high thicknesses.

The decision between hard and soft gold plating is critical, with various balances of durability, conductivity, and application-specific requirements. Hard gold plating is excellent for applications that require high stress and are wear-resistant, while soft gold is invaluable when higher electrical performance and bonding capabilities are required. Being familiar with each type of plating and its properties/strengths will greatly help in choosing the right ones for your designs and will improve functionality and the operating lives of components.

At PCBCart, we combine vast experience with a commitment to quality and insightful guidance through each step in making your gold plating decision. Whether it's a new project or refining existing technology, we provide solutions that cater to ensure optimal results. For a quote today, allow us to help you achieve outstanding performance and reliability in your PCB designs.

Get an Instant Quote for High-Quality PCB Assembly

Helpful Resources

• The Critical Role of Gold in PCB Fabrication

• PCB Surface Finishes Introduction and Comparison

• Guide to PCB Gold Fingers

• ENIG vs Immersion Silver: Surface Finish Comparison

• Guidelines for Surface Finish Selection