In the complex arena of electronics, the integrity of soldered joints is the cornerstone of electronics functionality. Nonetheless, one of the most ubiquitous problems that could potendy affect electronics integrity is the occurrence of cold solder joints. Faulty joints formed from inadequate soldering and poor interaction between leads and pads on printed circuit boards pose risks of intermittent electronics malfunction and failure. Regardless of whether you are an amateur electronics enthusiast or expert electronics engineer, learning ways of avoiding faulty cold solder joints is paramount.

Understanding Cold Solder Joints

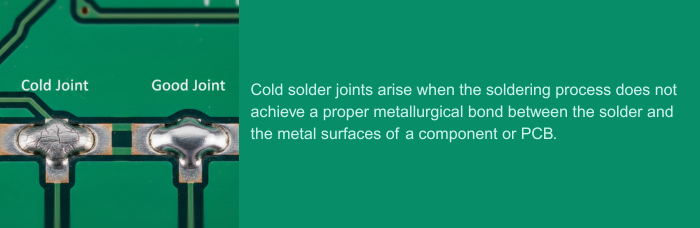

A cold solder joint is formed if there is no proper joining of the solder and the corresponding metal surfaces of either the component or PCB. The insufficient heat of the components and surfaces of the components and PCB can cause low-quality joining. If the components and PCB are joined with low-quality surfaces with the use of low-quality flux and while using lead-free solder, then also a cold solder joint may form. A cold solder joint can also appear dull and/or grainy and/or cracked. A perfect joint would appear shiny and smooth.

Why Cold Solder Joints Are Important

The consequences of cold solder joints for electronic assemblies can be substantial.For hobbyists, such joints can mean that their project does not turn out as expected. For professionals, the consequences can include expensive returns, product recalls, and potentially dangerous products. All such consequences can negatively affect the reputation of the brand.

Detecting Cold Solder Joints

It is imperative to spot a cold solder joint in order to solve any potential problems. Sometimes, a cold solder joint appears dull, irregular, or has signs of cracking. From an electricity perspective, it could be characterized by an intermittent path of current flow or total breakdown. Higher readings of resistance could also point to a problem, which should always be close to zero.

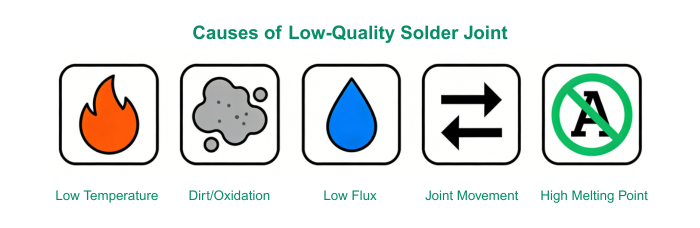

Causes of Low-Quality Solder Joint

Insufficient Heat: It is one of the major reasons where the solder doesn’t attain its melting point, thus resulting in low solder flow with poor bonding.

Contaminated Surfaces: Dirt, oil, and oxidation accumulate oncomponent leads or pads, forming a barrier that inhibits solder adhesion.

Insufficient Flux: Flux is required for removing the oxide layer on the metal surface and thus improving adhesion. Insufficient flux may prevent the formation of a strong joint.

Movement During Cooling: If there is movement to a joint during the cooling phase of soldering, the solder can become flawed, resulting in joints with cracked solder.

Challenges with Lead-Free Soldering: Due to their increased temperatures of fusion and differences in solder flow soldering lead-free solders requires very careful handling to avoid forming cold solder joints.

Approaches To Prevention

Optimal Soldering Temperature: It is recommended that a temperature-controlled soldering iron be used. This is set depending on the type of solder being worked with. Generally, the range is 260°C to 315°C for the case of lead-based solder and 300°C to 350°C for the case of lead-free solder.

Surface Preparation: Clean the surfaces where you will be doing the soldering using isopropyl alcohol. When a solder with a flux core is used, it helps to create a better bonding between surfaces.

Appropriate Flux Usage: Select the appropriate flux depending on the usage scenario – rosin for general use, no-clean flux for low residue usage, and water-soluble for harsh environments. This will assist the cleaning process for increased solder flow and bonding capability.

Effective Soldering Methods: To form a good connection, touch both the PCB and the component leads simultaneously using a soldering iron. Allow the solder to flow and do not apply excessive amounts of solder to form solder bridges.

Use of Quality Tools: Invest in quality soldering equipment like magnifying tools for viewing, desoldering pumps for error correction, and even workplace organization tools for preventing interruptions during the soldering process.

Handling Lead-Free Solder

Environmental compliance may require the use of lead-free solder. This solder may be more beneficial. However, it also comes with more challenges in terms of higher melting points and the properties of the solder when it melts. However, you can be able to handle the effects of the solder’s rapid cooling properties by using the right temperatures and flux. Practice more effective ways of dealing with the rapid cooling effects.

Fixing Cold Solder Joints

Despite proper preventive measures, cold solder joints may develop. To fix cold solder joints, one has to reheat the joint to its melting point and add new flux. It is also useful to add a little amount of new solder. To achieve good conductivity, one has to make sure that there are no disturbances while cooling. The repaired joint should ideally have a smooth and shiny surface.

Cold solder joints are one of the biggest problems faced by the electronics community. As mentioned earlier, joints which lack sufficient heat and are contaminated with debris can become problematic. Utilizing knowledge to prevent such issues from becoming problematic is possible with effective soldering temperatures, clean joints, and proper soldering techniques. Applying such knowledge is crucial to prevent such issues from becoming problematic. This is applicable for professionals or hobbyists to provide joints with endurance.

PCBCart is at the cutting edge of PCB manufacturing and provides unmatched expertise and capabilities for even the most complex soldering requirements. Our dedication to excellence and accuracy is designed to ensure that each and every PCB delivered is of the highest standard and performance requirement. With the latest equipment and a qualified personnel team, we at PCBCart have the capability to handle all the issues that could be generated by cold solder joints and prevent such problems in your PCBs. Try the best that we can offer and experience the best by sending us a quote request.

Get an Instant Quote for High-Quality PCB Assembly

Helpful Resources

• Elements Influencing SMT Soldering Quality and Improvement Measures

• Contrast on Soldering Technologies Used in Lead and Lead-Free Reflow Soldering

• Automated Optical Inspection (AOI) for SMT Assembly

• PCB Surface Coating Functions and Selecting Principles

• Process Control Measures to Stop Defects in SMT Assembly

• How to Prevent Poor Solder Wetting