Legend printing, or silkscreen/overlay, is an integral function in printed circuit board assembly, or PCB, and greatly increases the usability and functionality of a printed circuit board. Although printed circuit board legends can be considered a minor aspect of printed board design, their impact on PCB assembly, testing, and maintenance is rather great.

Importance of Legend Printing of PCB

PCB legends consist of text, symbols, and markings placed upon a surface that contain fundamental information critical to assembly and maintenance. Usually located upon a soldermask surface layer, these serve as a guide that helps assembly and maintenance professionals in mounting components in a fashion that aims towards a positive outcome.

Key Benefits

Streamlined Assembly: The presence of clear and readable legends minimizes the possibility of assembly mishaps since they contain simple instructions for the assembler on where to assemble and how to assemble the components.

Better Troubleshooting: Legends assist in troubleshooting a circuit easily because they contain test points and the identity of components.

Improves Communication: Information presented on the PCBs can be shared easily among the designers, assemblers, and technicians, thanks to effective labeling.

Basic PCB Legend Design Principles

Fundamentals of Design Rules

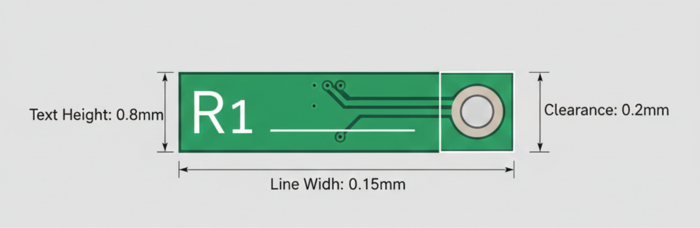

Text and Symbol Size: Text height should be at least 0.8 mm (31 mils), and the width of the lines should be 0.15 mm (6 mils) to ensure clarity. Such text and symbol-size guidelines satisfy most manufacturing requirements.

Clearances: Maintain at least a 0.2 mm (8 mils) gap between legends and solder pads or vias, which helps prevent solder bridging and facilitates smoother assembly.

Orientation: Orientation of text and symbols to retain focus from one perspective, mostly from left to right as industries read.

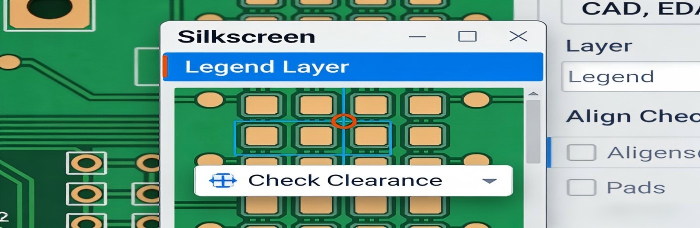

Layer Management: You are responsible for linking the legends to the appropriate layer within the PCB design environment, usually named “Silkscreen” or “Overlay.”

Readability Standards

Contrast: Use strong contrasting color schemes, and this should include using white text against a soldermask of either green, black, or blue backgrounds.

Font Choice: Use simple, sans-serif fonts such as Arial and Helvetica, as they retain their clarity and resist distortion during the printing process.

Controlling the Content: There shouldn't be clutter in the content that is displayed in the legend. Only the necessary information needs to be there. Proper spacing between the different elements helps create a clear difference, thus

Writing the PCB Legend Effectively

When creating PCB legends, the key should be to include data that has direct application in assembly and maintenance, such as the following:

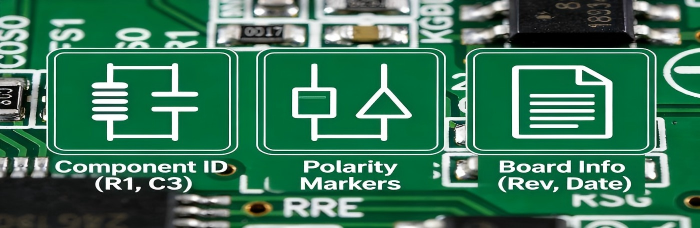

Component Identification: The use of reference designators like R1, C3 corresponding to the schematic serves to ensure the accurate placement of components.

Polarity Indicators: It is necessary to provide polarity indicators for areas where diodes and capacitors are involved.

Board Information: Details like revision numbers, manufacturing dates, and guidance on how to comply with the board, preferably positioned near the board edges.

Best Practices in PCB Legend Printing

Implementation of industry best practices can greatly improve the legibility of your PCB legends:

Prioritization of Information: They recommend placing important data, like orientation and polarity indicators, near related components, and where secondary data is of less importance, it can be placed elsewhere.

Standard Symbols: Use global symbols to facilitate understanding among different teams and in different locations.

Assembly Process Considerations: Legends should be located in such a manner as to support and aid both manual and automatic assembly operations.

Advanced Techniques in Legend Printing

The selection of the right printing technology is imperative for ensuring the legends are of high quality:

Silkscreen Printing: This is a relatively inexpensive printing technique where mesh stenciling is employed in the production of medium-sized to large orders.

Direct Legend Printing: With the inkjet technology, direct legend printing offers maximum precision, thus suiting the printing of prototypes or small projects where details are required.

Material Compatibility: The ink should be material-compatible with the PCB's soldermask and resistant to processes involved in assembly, such as soldering and cleaning.

Common Pitfalls and Avoidance Strategies

Common mistakes to avoid for proper legend printing:

Undersized Text: Make sure the textual size meets the optimum size requirements for easy viewing.

Overlapping Elements: Design for the easy distinction between legends and devices, with no interference in solder pads or vias.

Noncompliance with Manufacturer Guidelines: Make sure you are in line with your manufacturer’s specifications to avoid any redesigns and delays in production.

Legend Verification Prior to Production

A good practice would be to validate that your printed circuit board (PCB) has a correctly placed legend prior to mass production. The following are some

Digital Preview: Utilize the software to create a digital preview of how the legends will print and how they will be aligned once finished.

Prototype Testing: Testing small production runs for legend clarity and location when handled as in real-world use.

Collaborative Feedback: Gain feedback from other team members and assembly teams about the design’s functionality and ease of use.

Legend printing is the most crucial part of PCB design and has gone beyond the boundaries of aesthetics, as it has become a significant factor in the efficiency and reliability of manufacture and, by extension, the manufactured products as well. With the integration of necessary principles, the harmonious adherence to the most stringent level of readability, and the use of advanced technology, it is possible to develop readable and robust legends, ensuring smooth assembly and maintenance processes and the trouble-free functioning of every single PCB board.

At PCBCart, we strive to provide you with the best quality PCBs, together with the added benefits of our professional legend printing services. Our advanced facilities and professional technicians guarantee all of our PCBs are made with the highest quality, together with the finest printed legends for better functionality and clarity. We look forward to you requesting a quote from us, so you can experience the benefits of PCBCart, where the best of technological advancement blends with the best customer service, all of which are designed to cater to your specific needs for PCB production.

Request for Advanced PCB Assembly & Manufacturing Quote

Helpful Resources

• Design Requirement of SMT PCBs Part Four: Mark

• Common PCB Design Issues

• A Beginner’s Quick Guide to PCB Layout

• Design for Manufacture and Assembly of PCBs

• PCB Surface Finishes Introduction and Comparison

• Free DFM Check