In the electronics design world, where complexity reigns, Printed Circuit Boards (PCBs) are the platform on which various components are brought together and formed into a singular functional unit. While there is as much value placed on electrical layout and component positioning, mechanical aspects — particularly fixing holes and assembly holes — play a pivotal role in forming a PCB design into a physically realized, optimized product. This article addresses the generally secondary but necessary functions these holes serve in design and manufacturing.

Mounting Holes vs. Tooling Holes

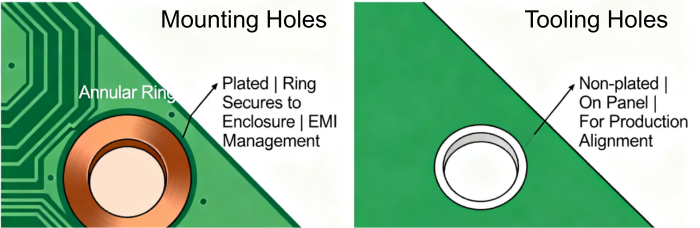

Although sometimes ambiguous, mounting holes and tooling holes are different from each other regarding functions and applications in PCB fabrication and assembly processes.

Mounting Holes

Fixing holes, also known as mounting holes, are used to physically secure the PCB to its enclosure or chassis. Mounting holes refer to mechanical features that ensure safe insertion of a PCB into an enclosure or chassis. Typically larger than other board holes, the holes are placed strategically—at corners or otherwise strategic locations—surrounded by an annular ring or copper pad. The annular ring provides mechanical support and may serve as electrical grounding when plated. Plated mounting holes can link multiple PCB layers, assist with electromagnetic interference (EMI) management, and serve as good anchor points for fastening hardware so that components remain securely mounted to the board.

Holes in these positions can be used for dual mechanical and electrical purposes: mechanically holding the chassis in place as well as allowing current conduction between layers when necessary. Avoiding interference from mounting hole locations with important signal paths is critical to signal integrity and component operation.

Tooling Holes

Assembly holes, often termed tooling holes, are used during the manufacturing and assembly process. Tooling holes, however, are required for alignment of a panel during production to facilitate mounting on a worktable or panel setup. Tooling holes are, in contrast to mounting holes, non-plated and production-standard to fit manufacturing tools without necessitating custom setup. Tooling holes are positioned by design on the panel and not on individual boards, allowing them to be handled efficiently during panelization—when multiple PCB designs are manufactured together for economical manufacturing.

Tooling holes provide precise locating and orientation during manufacture, reducing errors and enhancing efficiency. Their fixed position ensures compatibility with automatic processes, optimizing fabrication and assembly efficiency.

Best Practices for Hole Placement and Design

Adoption of conscientious design practices for holes in PCBs is invaluable to simplify manufacturing processes and ensure product reliability.

Panelization Concerns:

Holes for tooling are a part of panel configurations designed by the manufacturers to reduce manufacturing operations. Placing them in the panel rail or corners enables several boards to be managed and processed economically. Designers are able to custom-design panels, but PCB manufacturers tend to do this as an additional service, factoring the setup fee into the non-recurring engineering (NRE) fees. The process offers standardization and precision to repeated production runs.

Panelization enables the parallel production of several PCBs, making production more efficient. Designers have to work in tandem with manufacturers to design panels to optimize material use while allowing easy separation of individual boards after production.

Plating and Electrical Considerations:

Mounting hole plating involves making sure that they establish good electrical contact to a ground plane, copper pour, or ground trace. This design is important in EMI shielding and also in heat dissipation by transferring the heat to metal fasteners which can be utilized as heatsinks. Proper grounding of mounting holes will also prevent electrical noise from disturbing the functionality of the PCB.

Practical considerations include the establishment of board thermal characteristics and proper provision for heat-conductive paths in the PCB layout. Mounting holes can assist in pulling heat away from heat-sensitive components, contributing to reliability and life.

Orientation Fiducials:

To accomplish accuracy in automated assembly operations, fiducial markers must be placed in three corners of the PCB design. Fiducial markers assist during correct orientation during stencil printing, component mounting, and inspections, and this removes potential mistakes in automated operations substantially. Properly aligned fiducials provide more precise assembly procedures, hence high-quality consistent outcomes.

Economical utilization of fiducials enhances component placement accuracy and reduces the potential for defects. Alignment of such markers with holes for tools ensures smooth transitions from one production phase to the next.

The application of considerate fixing and assembly holes in PCB design is critical to structural integrity as well as efficiency in manufacturing. Having knowledge of the operational difference and design needs of mounting holes and tooling holes, engineers will simply be able to move their designs from the idea stage to implementation. An emphasis on these often-overlooked details can lead to more efficient products and streamline the manufacturing process, which is critical within the evolving electronics industry.

Where making your PCB layouts a reality is concerned, PCBCart is your trusted partner. With extensive expertise in the production and assembly of PCBs, we provide customized, precise solutions attuned to your project's unique demands. Our cutting-edge facilities and strict focus on quality ensure that every detail—whether plating needs or panelization—is carefully addressed. By quoting PCBCart, you are not just getting yourself linked with industry-best services, but you also get access to huge knowledge and expertise so that your designs get produced at the best quality. We'll assist you in bringing your innovative designs to life as working, high-quality products meeting and exceeding market demands.

Get an Instant Quote for High-Quality PCB Assembly

Helpful resources:

• PCB Design for Manufacture and Assembly of PCBs and General Rules it Conforms to

• PCB Manufacturing Process — A Step-by-Step Guide

• What is Surface Mount Technology (SMT)?

• How to Ensure the Quality of PCBs