In the fast-evolving world of PCB design, copper weight is one of the most elemental parameters that plays a significant role in the electrical performance, thermal management, and structural durability of the board. PCBs form the backbone of digital electronics, and their engineering requires precision to keep modern components mounted securely and in working order. At PCBCart, we understand the importance of choosing the right copper weight and hence offer different weights to help various designs. This article goes over the nuances of copper weights and focuses mainly on the most common types of copper weights: 1oz, 2oz, and 3oz-to explain their various roles, advantages, and applications.

Understanding Copper Weight in PCB Design

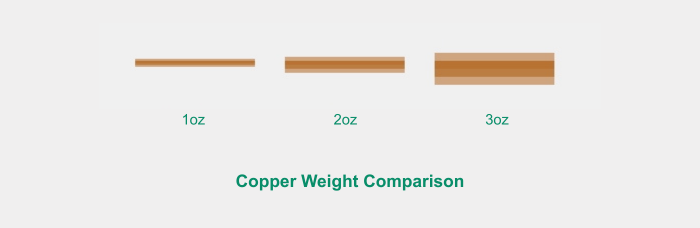

Copper weight is the thickness of copper applied over a 1 square foot area on a PCB and is usually measured in ounces (oz). It is an important measurement because it determines the board's electrical conductivity, thermal performance, and overall structural integrity. Here is a breakdown of commonly used copper weights in PCB manufacturing.

1oz Copper: This represents the general industry standard for many consumer electronics because it strikes a very cost-effective balance between performance and budget for a great many general-purpose applications. It is often preferred for designs where current and thermal demands are moderate.

2oz Copper: Ideal for applications that require higher power handling, like LED lighting systems and automotive electronics, where a larger current capacity is required to support more robust functionalities and efficiency.

3oz Copper: This is used where very high current capacity and durability are required, thus finding applications in very heavy industrial use and high-power transmission systems. The ability of this to withstand high power makes it useful in demanding situations.

Key Differences and Applications

Current-Carrying Capacity

The most important factor to consider when choosing the weight of copper is its current-carrying capacity. The greater the weight of copper, the thicker the copper trace will be, which can carry more current without overheating. This becomes an important feature when it comes to performance and reliability for high-power applications:

1oz Copper: Suitable for low to moderate current applications, such as consumer electronics, where power requirements are small. It can meet the needs of most household devices, portable gadgets, and simple electronics where high power is not a primary concern.

2oz Copper: It is ideal for applications requiring higher power handling, such as LED lighting systems and automotive electronics, where a larger current capacity is required to support more robust functionalities and efficiency.

3oz Copper: Required for high-power applications, like power distribution systems and industrial machinery, that require large currents. It is essential because it will allow the board to operate for an extended period without degrading in performance.

Thermal Performance

Thicker copper layers significantly improve the PCB's thermal management by allowing heat to be dissipated more effectively. That aspect has become important, especially where high-power applications are concerned, where overheating could lead to component failure or diminished performance.

For example, in power converters or high-performance computing systems, the temperature rise can be significantly reduced by using a 3oz copper weight, thus allowing components to safely operate within specified limits and thereby extending their life.

Mechanical Strength

Thicker copper increases the board's mechanical robustness, making it more resistant to physical stress during handling and operation. This increased durability could extend the operational life of the PCB, reducing the need for frequent repairs or replacement in unforgiving environments, such as automotive or aerospace electronics, where physical integrity is crucial under continuous motion and vibration.

Cost Considerations

Larger copper weights offer great benefits in performance but involve higher manufacturing costs because of more materials used and the complexity in the processing required. A designer has to balance the performance advantage against the budgetary constraint. We work closely with our clients at PCBCart for a proper copper weight selection, matching performance needs to financial constraints to achieve efficiency at an affordable price.

Practical Applications of Copper Weights

1oz Copper

Most commonly, this copper weight is used in consumer electronics and other low-to-moderate power applications where the combination of performance and cost is at its best. It will suit everything from very simple devices to more sophisticated electronics where budget considerations are a factor. Examples include home automation devices, portable electronics, and general-purpose gadgets.

2oz Copper

This weight is widely adopted in applications where superior electrical and thermal performance is necessary, such as automotive electronics, power supplies, and LED lighting systems. It provides a higher threshold for power and heat without significantly driving up the cost, hence preferred for many mid-range to high-performance applications.

3oz Copper

Essential for high-power, high-reliability applications commonly required in industrial machinery and large power transmission systems, the 3oz copper provides substantial current capacity and durability. Ideal for applications requiring superior robustness, where performance cannot be compromised over a long period, it ensures reliability and longevity. Typical applications involve industrial power distribution, high-end motor control systems, and large-scale power inverters.

Copper weight is one of the most important elements in PCB design, which influences three significant aspects: current capacity, thermal management, and structural integrity. Thus, the awareness of the specific advantages of 1oz, 2oz, and 3oz copper weights will provide engineers and designers with the opportunity to make decisions that positively affect product reliability, durability, and functionality. Whether consumer electronics or robust industrial systems, selecting the proper copper weight is another vital step toward the realization of concepts into viable, functional products.

At PCBCart, we are dedicated to providing top-notch PCB solutions to help fulfill your needs. Combining extensive experience with a commitment to quality means that your projects are handled with precision and care. For modern electronics, the application of different requirements also requires copper weight and customized solutions. Partnering with PCBCart secures a balance in your need for attention to detail, innovative approach, and concern for your success. Contact us today for a quote to see how PCBCart can help you achieve excellence in your PCB designs.

Request for High-quality PCB Assembly & Fabrication Quote

Helpful Resources

• Relationship between Copper Weight, Trace Width and Current Carrying Capacity

• PCB Thermal Design Considerations

• Heavy Copper PCB Fabrication Technology

• How to Choose Thickness for Your PCB Prototype?

• Power Electronics PCBs Guidelines

• PCB Material Selection Based on Electrical Performance