In the current highly competitive manufacturing environment, precision and efficiency are not a bonus—they are an absolute necessity. As companies compete to manufacture quality products, box build assembly is a defining step in manufacturing. This article aims to inform readers of the intricacy of the box build assembly in order to enable professionals, as well as hobbyists, to have the insight necessary to learn and apply this complex process with confidence.

Comprehending the Box Build Assembly Process

Box build assembly process, often referred to simply as "box build," is at the core of electronic product manufacturing. It involves the final phase of mounting electronic components into a case so that they become a usable end product that can be deployed into the marketplace. The process applies to various industries like electronics, automotive, aerospace, and telecommunications, each having different requirements and standards.

Major Components of Box Build Assembly

The box build assembly process is understood on the basis of a complete understanding of its major components:

Enclosures: The outer protective cover that accommodates the internal components and gives them their structural strength and protection. Enclosures must be industry-compliant and resilient to ensure that components are safeguarded against environmental factors.

Electronic Components: The build includes an extensive array of components ranging from printed circuit boards (PCBs) and wiring harnesses to sensors, displays, and programmable logic controllers (PLCs).

Connectivity: Critical to the box build process is ensuring there are seamless connections between components. This involves accurate wiring and meticulous connectivity testing to ascertain that the product functions as intended.

Quality Control: Continuous quality control procedures should be integrated in the assembly process to ensure the performance and reliability level of the product.

Documentation: Schematics, assembly documentation, design documentation, and precise documentation is necessary to help ensure consistency, troubleshooting, and supporting any post-production enhancement or modification.

Step-by-Step Box Build Assembly Process

Design and Planning

The process begins with intensive design and meticulous planning. It involves creating detailed blueprints and schematics, selecting appropriate components, and outlining precise assembly procedures. Meticulous planning minimizes risks and makes the entire assembly process easier, serving as a guide for the subsequent stages.

Component Preparation

Before assembly, sub-assemblies and parts are gathered, inspected, and processed to their readiness. This includes ensuring their quality and performance up to high levels. Proper marking and classification of parts ensure efficiency during the assembly process, eliminating errors.

Assembly

This stage entails physical mounting of parts into the casing. Trained technicians use strict guidelines to mount the parts, taking precision and accuracy. All parts need to be fitted in the right position in order to allow the final product to work at its best.

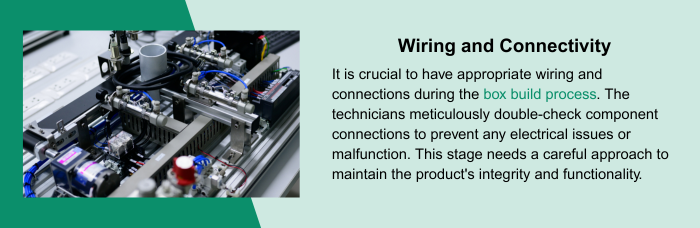

Wiring and Connectivity

It is crucial to have appropriate wiring and connections during the box build process. The technicians meticulously double-check component connections to prevent any electrical issues or malfunction. This stage needs a careful approach to maintain the product's integrity and functionality.

Testing and Quality Control

Quality control becomes part of every step of the box build assembly. There are stringent testing processes to identify any defect or anomaly. The quality checks ensure that the final product is of acceptable quality and is in compliance with industry standards.

Final Inspection and Documentation

A rigorous final check is conducted prior to shipping the product. This is to confirm that the assembly adheres to the original design spec and the requirements of the customer. Documentation of the entire assembly process, such as test results and any deviations in the plan, are retained for future reference and improvement.

Challenges in the Box Build Assembly Process

Most as it is, the box build assembly process is plagued with problems:

Component Compatibility: With multiple components being able to function properly together, making it sometimes complicated to select, work with, and test for exclusion of functional conflicts.

Complicated Wiring: As gadgets become more advanced, wiring and connections become more complicated. This makes higher demands on the precision of technicians and can be a major problem.

Skilled Workforce: Accuracy required in the construction of advanced electronic components demands a highly skilled workforce. It is hard to have and train a skilled team but is worth it for achievement.

Importance of Effective Box Build Assembly Process

Effectiveness of the box build assembly process has a direct impact on many critical business results:

Product Quality: Product quality is a result of a meticulous and efficiently carried out box build process, ensuring reliability and high performance.

Customer Satisfaction: Meeting or exceeding the expectations of the customers is of top priority. Ideal assembly process translates into greater customer satisfaction and loyalty.

Efficiency: Ideal assembly process translates into efficiency, minimum production time, and costs which are necessities to maintain a competitive advantage.

Compliance and Safety: Compliance with standards of the industry and safety norms is inevitable. Effective assembly process guarantees compliance and safety of the product.

In short, the box build assembly process is the most important to successful electronics manufacturing, enabling the transformation of components into finished products. Understanding its building blocks and roadblocks, along with teamwork with industry experts, can lead producers into a level of efficiency never experienced before and product quality supremacy.

PCBCart is a premier choice for all your box build assembly requirements, where industry experience and unwavering commitment to quality and precision come together. Our professionals are trained to design affordable solutions that cater to your individual needs and reduce lead times. By selecting PCBCart, you get to enjoy our streamlined manufacturing processes, lesser chances of miscommunication, and high standards of product output consistently. We invite you to experience the difference that professional partnership can make in achieving your manufacturing goals—contact PCBCart today to request a quote and take your production capabilities to new heights.

Get an Instant and Free Quote for Box Build Assembly

Helpful resources:

• Applications and Types of PCBs for Telecommunications Industry

• PCB Materials

• High Volume PCB Assembly

• Comparison between Wave Soldering and Reflow Soldering

• Effective Measures to Improve SMT Assembly Quality