In the complex electronics industry, PCBs are the core component of every machine, both the technical industry and the consumer device. The decision to use surface finish is very important to achieve maximum performance and reliability of these machines. Immersion tin surface finish has been one of the possible options, which have proven effective as a cost-effective solution in various alternatives because of its peculiarities. This paper is an in-depth discussion of immersion tin surface finish, including information about its advantages, disadvantages, and the working features of technology in the framework of contemporary PCB production.

Understanding Immersion Tin Surface Finish

Immersion tin also known as white tin is a coating on PCBs which is achieved through an electroless chemical process. This is a process that coats a thin and homogeneous coating of tin on the naked copper traces, pads and vias of a PCB. The product is a metallic coating which does not only prevent copper from oxidizing, but also gives it a flat solderable surface needed in contemporary dense electronic designs. Of all finishes, immersion tin has the benefit of providing a consistently applied and uniform protection layer usually ranging between 0.8 and 1.2 micrometers, unlike other finishes that may need the use of electric current to be deposited on.

The Benefits of Immersion Tin

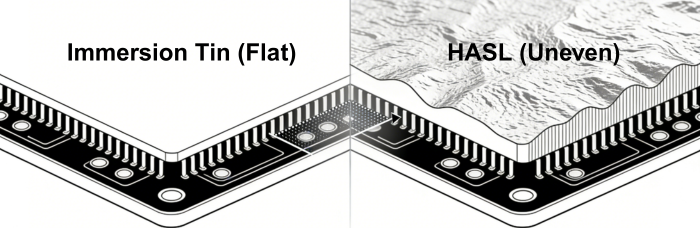

Excellent Planarity

One main advantage of using immersion tin is that it has the potential to have a constantly flat finish. This characteristic is especially beneficial to the assembling of fine-pitch components such as Ball Grid Arrays (BGAs) and Quad Flat Packages (QFPs). Its immersion tin provides a level surface, unlike other finishes like HASL (Hot Air Solder Leveling), which may cause the creation of uneven surfaces and may cause component placement to be inaccurate or misaligned.

Cost-Effectiveness

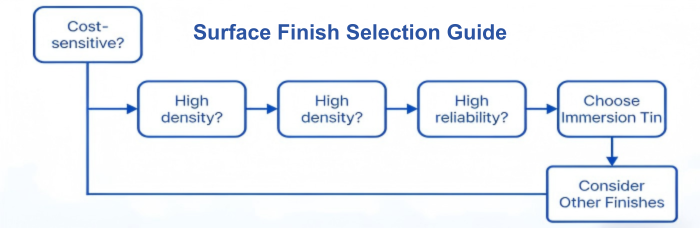

Immersion tin is an excellent product in regard to economic efficiency. It is usually cheaper than higher-end finishes such as ENIG (Electroless Nickel Immersion Gold) and therefore permits manufacturers to produce satisfactory performance at a relatively low cost. This is what makes immersion tin especially attractive to cost-conscious projects, such as consumer electronics, prototyping, and other projects where one has to stick to a very rigid budget.

Pollution Free and Clean

Since the electronics industry has been moving towards the idea of environmental friendliness, immersion tin can be considered as a lead-free option that can meet the requirements of the RoHS (Restriction of Hazardous Substances) directive. The enforced compliance renders it a choice to businesses that endeavor to minimize hazardous substances consumptions as well as stick to the international environmental guidelines.

Enhanced Solderability

Immersion tin is known to be solderable and it produces durable solder joints. It is also strong when subjected to a number of reflow cycles, which are normally needed in the current assembly. Its conformity with lead-free solder procedures can aid in maintaining consistency and reliability of the manufacturing of the final electronic product and the overall quality and durability.

Limitations to Consider

However, immersion tin is not without its challenges as highlighted despite its benefits and therefore needs to be taken into account so as to utilize its full potential to the best.

Short Shelf Life

The major weakness is that it has a low shelf life. The coating could begin to oxidize when it is stored poorly or in periods that would usually take more than six months. In the absence of suitable storage environments, preferably at low temperatures and dry conditions, the surface may lose its solderable properties and the assembly will fail to yield quality outcomes as well as the cost of production will go up as a result of wastage.

Possibility of Tin Whisker Development

Pure tin finishes have a history of forming tin whiskers. These are microscopic metallic spikes which may possibly lead to short circuits when they connect two traces or pads on PCB. This is a particular cause of concern in high-reliability systems such as aerospace or medical devices, where failure of equipment can be severe. Things such as conformal coating can be used as mitigation measures, but this complicates and increases costs when manufacturing.

Vulnerability to Handling Damage

Immersion tin is sensitive on its surface which can easily be spoiled by scratches, contaminants or by fingerprints. This may affect the solderability and integrity of the surface and therefore, there must be strict handling and storage measures to ensure functionality and performance are not impaired during the assembly process.

Real-life Immersion Tin Applications

Immersion tin has its niche in those situations where the factor of budget brevity is the most important, as well as the necessity to have a good solution, yet not necessarily durable. Its application is common in consumer electronics, telecommunication and those applications where fine-pitch component placement is required but where environmental extremes are not a concern.

It is due to these reasons that immersion tin is still a favorite option when it comes to cost effective projects that are performance and cost effective. Nonetheless, in applications requiring ultimate strength, e.g. in motor or military industry, alternative finishes can prove to be more fitting, although more expensive.

Some PCB Designer Things to Keep in Mind

When using immersion tin in your PCB structure, these are the factors that should be considered:

Application Requirements: Evaluate the requirements in reliability versus the cost limitations. Immersion tin is effective in low cost and high volume projects.

Storage and Handling: Instill strict storage and handling measures that will lengthen the shelf life and preserve surface integrity.

Component Density: Make use of planarity of immersion tin on layouts of dense component placement, but conduct tests to confirm compatibility.

Mitigation Strategies: Discuss mitigation measures like conformal coatings to solve tin whiskering problems, especially in high reliability design.

Immersion tin provides a compelling combination of cost, solderability and planarity, and is a good choice where price, fine-pitch component assembly or both are of interest. But its drawbacks, including shorter shelf life, and the possibility of developing tin whiskers make it not always perfect. By carefully evaluating these aspects together with the unique needs of the particular project, such as what type of application the immersion tin will be used in, how much they will be exposed to the environment, and how much they will be required to withstand, designers can decide whether immersion tin is the correct choice in their PCB production.

At PCBCart, we are into high-quality PCB manufacturing solutions that are designed in accordance with various design requirements. We have a lot of experience in surface finishes which include immersion tin, this means that your project will be in the current technology of PCB. PCBCart is determined to give customer excellence, both on the quality of the products and customer service. Our advanced production plants and a tradition of accuracy and dependability make us the right choice to develop any complicated electronic design into reality. We also encourage you to get a quote from PCBCart today and enjoy quality PCB manufacturing and expertise unmatched anywhere else.

Request for High-quality PCB Assembly & Fabrication Quote Now

Helpful Resources

• The Most Comprehensive Guidelines for Surface Finish Selection

• PCB Protection: Potting or Conformal Coating?

• Contrast on Soldering Technologies Used in Lead and Lead-Free Reflow Soldering

• Factors Affecting the Quality of BGA Assembly

• How to Ensure the Quality of PCBs

• Common Defects in PCB Assembly and How to Prevent Them