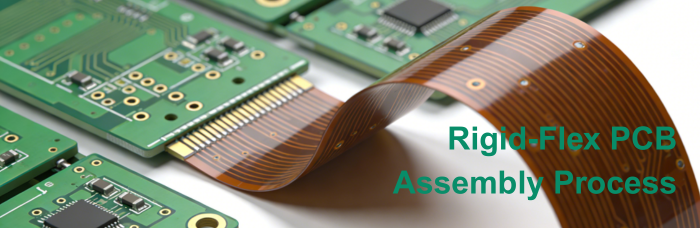

In today’s ever-evolving technology-driven environment, there has been unending pressure for the development of miniaturized, high-performance, and multifaceted gadgets. The rigid-flex printed circuit board has proved to be one of the hallmark technologies that can fully satisfy the above requirements. These types of boards combine the strengths of rigid PCBs with the flexibility of flexible PCBs. In this article, we will broach on the intricacies associated with assembling rigid-flex PCBs and why they cannot be ignored in today’s technological revolution.

Rigid-flex PCBs are hybrid PCBs that combine various layers of rigid and flex PCBs in such a way that their functionalities are harnessed jointly. This approach to PCB manufacture gives rise to many advantages, such as weight reduction, compact design, and reliability. Rigid-flex PCBs are, therefore, essential in aerospace, automotive, consumer electronic, and medical industries, where compact design and reliability are of paramount importance.

Design and Planning

The assembling phase begins with an important step named design and plan layout. The design plan layout is a backbone in successful PCB assembling. The engineers make use of advanced computer-aided design tools to design meticulous schemes that demonstrate the subtlety in trace routing, impedance, and component placement. The design needs to incorporate flexibility without stressing in failure, which is an important point to consider as these boards are flexible in operational running.

Material Selection

Material choice is a critical parameter that impacts the functionality and longevity of a rigid-flex PCB. This is mainly true since the flexible area usually incorporates high-quality polyimide films that are highly flexible and heat-resistant. On the other hand, the stiff area always incorporates FR-4 laminates. This acts as an important requirement since the structure always needs rigidity. This is the only factor that ensures the chosen adhesive materials and techniques are heat and mechanically strong to withstand the board's structural integrity.

Production of the Flex Layers

The creation of the flexible layers is a precision-based process that requires careful attention. The coppering of the polyimide layers is done using sophisticated methods such as vapor deposition. The drilling of the boards is also done with accuracy to create the vias needed for the electrical connections of the layers. This is a crucial part of the entire process as any deviation would cause major problems when it comes to the functionality of the board.

Layer Lamination

After the flexible circuits have been processed, the process of lamination of the rigid parts follows. Lamination is the most crucial stage where alignment and bonding of the rigid parts using the action of heat and pressure occur. Lamination ensures that no electrical shorts or signal problems are created in the board, which may affect the performance of the board.

Drilling and Hole Preparation

The next step would be precision drilling to create the required holes for via interconnections as well as through-hole interconnections. Depending on the size of the holes to be created and their accuracy, mechanical drilling as well as laser drilling would be used. This process is critical as the quality of the holes created will significantly influence the interconnections in the PCBs.

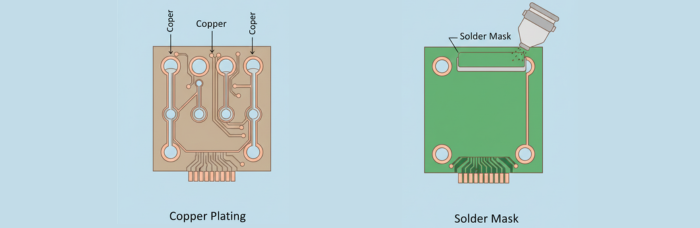

Plating and Solder Mask Application

After hole creation processes are completed, through-hole plating is conducted. This process enables the creation of robust connections. The next process is the use of a solder mask. This solder mask protects the circuit board against oxidation and helps in precise soldering. Also, the solder mask enhances the heating process within the board.

Component Assembly

The assembling of components uses fully automated surface mount technology (SMT). This is because the assembly requires picking and placing mechanisms, which are essential in handling fragile flexible substrates used in manufacturing circuit boards. Care must be taken in placing components on the board, which may look trivial, in order not to end up damaging them during assembly.

Reflow Soldering and Inspection

Reflow soldering, a process of bonding components permanently to the board, is done in a manner which circumvents the effects of thermal shock, which may cause stress to the flexible material. After the bonding process, the board is thoroughly tested by means of AOI, X-ray inspection, among others, which checks the alignment of components and any flaws like tombstoning or bridging.

Stiffener Attachment and Testing

For added structural robustness, particularly in areas that need to be strengthened, such as in the connection area, stiffeners are bonded using adhesive methods or thermal bonding processes. The resulting board now undergoes strict electrical verification to determine its functional capability and any possible inadequacies, such as an open or short circuit condition.

Final Inspection and Packaging

Prior to being considered ready for use, the board has to pass through a final inspection. This ensures that the board has met quality standards. The board is also protected by packaging techniques that prevent damage by electrostatic discharge and physical damage. This is achieved through the use of anti-static bags and moisture barrier bags.

The manufacturing of rigid flex PCBs requires a complex technology involving the challenges of both rigid and flexible PCB manufacturing. Every procedure requires precise implementation to yield a board qualified to meet the strict specifications needed by highly advanced technologies.

At PCBCart, our skills and knowledge allow us to provide high-quality, reliable, and functional products that cater to the ever-changing needs of various sectors. With the increasing call in the market for more portable and dynamic electronics, rigid flex PCBS play a critical role in technological advancement. For individuals working on new projects that harness the power of rigid flex PCBS, PCBCart is here to provide you with the skills and expertise to make your dream come true. Check out our website or get in touch with us to see more information on how our custom-built products can help push forward the technological revolution of tomorrow, realizing tomorrow’s innovations in technology, starting from today.

Request for Advanced Rigid-Flex PCB Assembly Quote

Helpful Resources

• Flex-Rigid Multi-Layer PCB Fabrication Process

• Material and Build-Up Construction of Flex-Rigid PCB

• Can't-Miss Engineer-Friendly PCB Layout Guidelines

• Common Defects in PCB Assembly and How to Prevent Them

• PCB Protection: Potting or Conformal Coating?

• Properties of Flex-Rigid PCB Used for Automotives