In the ever-changing area of electronics, Flex Printed Circuit Boards have made their presence felt in no small measure because of their malleable ability to bend, fold, and accommodate irregular spaces as well. These versatile boards are employed for various purposes in electronic devices such as smartphones to critical system components in cars and medical systems. However, it is also true that it is this very flexibility of Flex Printed Circuit Boards that sometimes poses particular functional and mechanical difficulties when it is required that particular sections of this flexible circuit be stronger in rigidity and sturdiness. That is where stiffeners become important.

What Are Stiffeners in Flex PCBs?

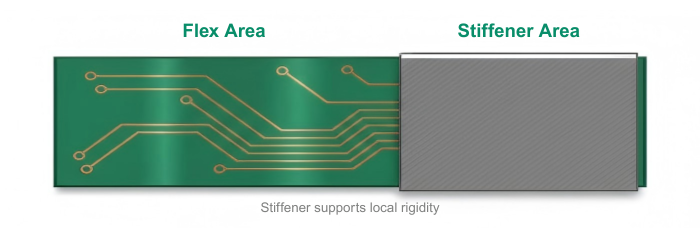

Stiffeners refer to the secondary parts that are attached to the Flex PCBs so that they can be supported and their structural integrity can be improved. Stiffeners in a circuit are not conductive, unlike other parts of the circuit. Stiffeners are important in supporting those parts of the Flex PCB that are vulnerable to stress and must be made rigid in order to be useful, especially during assembly.

Advantages of Using Stiffeners

In Flex PCBs, the addition of stiffeners has several benefits that are essential for the reliability and life of the PCBs:

Mechanical Reinforcement: Stiffeners offer the required rigidity in regions where components such as connectors and integrated circuits are mounted. Basically, it prevents unwanted flexure, thus the possibility of a mechanical failure.

Assembly Enabling: When assembled, the presence of stiffeners in the reflow soldering enabling automation process of manufacturing ensures a Flat PCB, which is vital for assembly correctness to be attained during the assembly stage.

Improved Component Support: Stiffeners reduce stress on the solder pads in areas of connectors that may be used and reused quite frequently, prolonging functional life for your PCB.

Thermal Management: Some of the stiffener materials act like a heat-sink by dissipating the temperature away from the critical components. This capability provides additional help for maintaining thermal stability and improving general efficiency in devices.

Vibration and Resonance Mitigation: Stiffeners reduce mechanical deformation, hence improving resistance to vibration and resonance of Flex PCBs, which is essential to safeguard the reliability of signals and the performance of the overall device.

Typical Materials for Stiffeners

The selection of materials for stiffeners is critical and is to a large extent dependent upon the requirements of intended use. The materials that are commonly used include:

FR-4: It has a high strength and a stable dimensional ratio, with flame-resistance properties. It can be found in applications such as stress relief areas and as a solid base for a variety of manufacturing processes.

Polyimide (PI): Because of its elastic properties and high heat resistance, polyimide is appropriate for situations in which there is a requirement for a light-weight stiffener material. Its ability to resist wear makes it suited for areas where there is contact with ZIF zero-insertion-force connectors.

Metal (Aluminum/Stainless Steel): Such metals ensure excellent mechanical strength, and their suitability in high thermal conductivity and corrosion-resistant tasks makes them commonly used in the automobile and heavy power segment.

Stiffener Placement and Layout

Stiffeners’ locations in a Flex PCB have a major impact on the board’s performance. There are a variety of arrangements that can be chosen from:

Top Layer Placement: Provides very good structural support for components placed on one side of the printed circuit board. It's very useful for weight distribution and avoiding stress concentrations.

Bottom Layer Placement: This assists in the addition of strength to areas that need to be reinforced, mostly the locations with active components that need to have added mechanical strength.

Dual Layer Placement: The use of stiffeners in both the top and bottom layers increases the overall stiffness of the board, which is necessary in environments where the board has to work under multidirectional stresses.

Techniques for Attaching Stiffeners

Essentially, there exist two approaches in securing stiffeners in a Flex PCB:

Thermal Bonding: This method involves the use of heat and pressure to generate a robust bond that is both durable and long-lasting. This method is quite effective but the equipment needed is quite costly; hence it is not applicable in all situations.

Pressure Sensitive Adhesives (PSA): With its greater malleability and relatively lower price, PSA provides good adhesion in situations where lower mechanical properties are needed or when removability is required.

Integrating Stiffeners in PCB Design

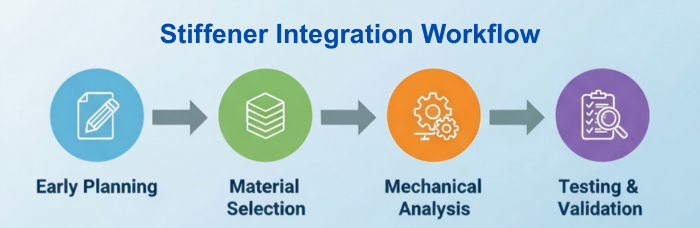

The integration of stiffeners must be one of the underlying principles within the design process for a PCB:

Early Planning: Stiffener requirements need to be taken into account from the initial stages of planning in PCB layout.

Material Selection: Material should be selected and compatible with the substrate used in the circuit board and the expected working conditions to get best results.

Mechanical Analysis: Simulation and mechanical assessment are to be performed to optimize positioning, as well as requirement for stiffeners that meet performance criteria.

Testing and Validation: Extensive prototyping and testing would be carried out in order to validate the effectiveness of stiffener implementations.

Stiffeners are an integral component in the improvement of the functionality as well as the reliability of flexible printed circuit boards or Flex PCBs. This is particularly important for thoseFlex PCB application areas that demand the ability of the printed circuit boards to withstand forces. Through the inclusion of stiffeners in the design of Flex PCBs, it is possible to balance the printed circuit board's ability to be bent as well as fit into compact areas. Through the use of stiffeners in Flex PCB technology, it is ensured that the reliability of the printed circuit boards is maintained in a wide range of application areas that include consumer electronics and the medical industry.

When it comes to the integration of stiffeners in your Flex PCB design, it is imperative to work with a company that has experience and is committed to quality. At PCBCart, we have over two decade of experience in the industry to offer the best possible Flex PCBs to suit your requirement. Our extensive range of stiffener materials, right from the tough FR4 stiffeners, flexible polyimide stiffeners, to our metal stiffeners, ensures that you have just the right fit. With our cutting-edge technology and commitment to precision, we are confident that we can provide you with nothing but the best possible products. Let us help make your design ideas possible. Reach us now at PCBCart and see how we can take your ideas to innovative heights with our superior Flex PCBs.

Get an Instant Quote for High-Quality Flex PCB Assembly

Helpful Resources

• Flexible PCB and Its Assembly Technology

• Material and Build-Up Construction of Flex-Rigid PCB

• PCB Thermal Design Considerations

• Effective Measures to Defeat Warpage Problem for PCBs

• Flexible and Flex-Rigid Printed Circuit Board Applications

• How to Ensure the Quality of PCBs